Ion exchange is particularly well suited to the separation

of biological molecules; however, limitations

of HPLC packing materials have restricted its use.

Silica-based ion-exchange materials are pH limited

and suffer from nonspecific interactions, although

they can have high efficiency. Porous, polymer resin-based

materials may be used over a wide range of pH

and have a high capacity (dynamic binding capacity

~45 mg/mL); however, they exhibit lower efficiency

and have pressure limitations. Nonporous resins

with fast mass transfer characteristics are efficient

but have extremely low capacity (<5 mg/mL). The

desire to analyze large numbers of charged components

in proteomic samples has driven the search for

improved ion-exchange columns.

Experimental

A nonporous, polymer resin particle was modified to

address the needs of ion-exchange separation. First,

a 200-Å-thick hydrophilic layer was chemically

bonded to the polystyrene/divinylbenzene (PS/DVB)

surface to virtually eliminate nonspecific binding

with biological molecules. Then, a densely packed,

uniform ion-exchange layer was chemically synthesized

to the hydrophilic layer. Multiple ion-exchange

functional groups were attached to one anchoring

point, resulting in a breakthrough in capacity. The

four varieties (SAX, WAX, SCX, and WCX) have

dynamic binding capacities ranging from ~20 mg/mL

to over 50 mg/mL—for example, 20, 38, 53, and 65

mg/mL for Proteomix SCX-NP resins (Sepax Technologies,

Newark, DE) with particle sizes of 10, 5, 3,

and 1.7 μm, respectively.

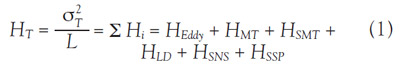

Separation efficiency can be described in terms of

plate height, HT in Eq. (1).1 Efficiency is defined as the

standard deviation (σ2) divided by the bed or column

length (L), and it is the sum of HEddy, HMT, HSMT, HLD,

HSNS, and HSSP, which are plate heights contributed

by eddy diffusion, mobile phase mass transfer, stagnant

mobile phase mass transfer, lateral diffusion, stationary

phase nonspecific interaction, and stationary

phase specific interaction, respectively.

Eliminating the pores minimizes the contribution

from stagnant mobile phase mass transfer. The

hydrophilic layer makes the nonspecific interaction

factor negligible.

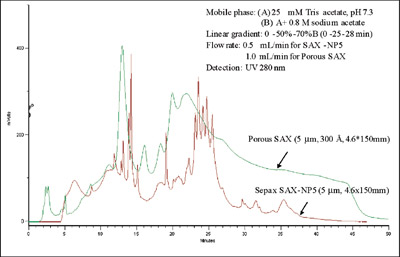

Figure 1 - Separation of horse serum (20 μL, 2× diluted) on 300-Å porous SAX

column compared to nonporous Proteomix SAX.

Figure 1 compares the separation of horse serum

on a traditional 300-Å porous ion-exchange column

to that achieved on a nonporous Proteomix

SAX. Both are 5-μm, 4.6 × 150 mm columns.

Capacities are equivalent, but efficiency and resolution

are significantly improved on the nonporous

resin.

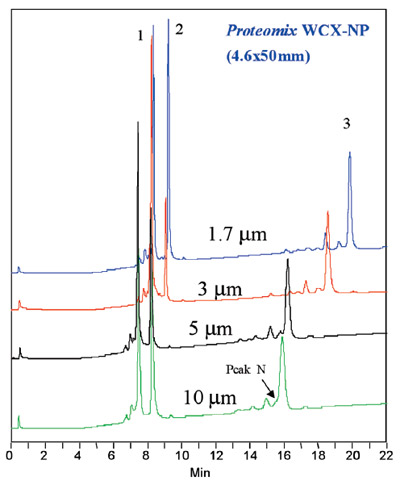

Figure 2 - Separation of a protein mixture using four

Proteomix WCX-NP columns with particle size ranging from

1.7 μm to 10 μm. Separation conditions—Mobile phase A:

20 mM phosphate-buffered saline (PBS), pH 6.5. Mobile

phase B: A + 1.0 M NaCl. Gradient: 0–100% B in 20 min.

Flow rate: 1.0 mL/min. Pressure: 10 μm, 540 psi; 5 μm,

890 psi; 3 μm, 1600 psi; 1.7 μm, 3100 psi. Detection: UV

at 280 nm. Proteins (1.0 mg/mL each): 1) ribonuclease A,

2) Cytochrome C, 3) lysozyme.

Particle size also plays an important role in efficiency

and resolution. Decreasing particle size

increases efficiency but dramatically increases

backpressure. Commercialization of ultrahigh-pressure LC instrumentation enables the use of

very small particles.2 Traditional resin-based ion-exchange

materials have been unable to withstand

the additional backpressure. The upper

pressure limit for Proteomix nonporous packings

is 10,000 psi, which enables their use in UPLC™

(Ultra Performance LC™) systems (Waters, Milford,

MA) and other high-pressure systems. Figure

2 shows a separation on four different particle

sizes of Proteomix WCX-NP from 10 μm to 1.7

μm. Note the resolution of the small peak adjacent

to lysozyme.

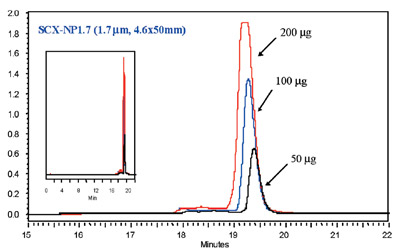

Figure 3 - Loading capacity test elution of Cytochrome C (20 mg/mL).

Separation conditions—Mobile phase A: 20 mM PBS. Mobile phase B: A + 1.0

M NaCl. Gradient: 0–70% B (21 min). Flow rate: 0.35 mL/min, 2800 psi.

Detection: UV at 280 nm.

A loading experiment using Cytochrome C, shown

in Figure 3, demonstrates a high capacity

while maintaining performance for the

1.7-μm nonporous material.

Conclusion

The use of nonporous resins improves

mass transfer and allows smaller particle

sizes to dramatically improve

efficiency in any pH range. Chemical

modification to eliminate nonspecific

binding and optimize ion-exchange

capacity overcomes the limitations

of classical nonporous resins. Ion-exchange

chromatography using nonporous,

specially modified resin-based

packings should become

a widely used tool for the

analysis of large numbers of proteins, low-abundance

protein detection,

and monitoring of

protein post-translational modification,

as well as the analysis of other

biological molecules. They should

also find use in pharmaceutical

applications in which small ionic

solutes can be difficult to retain by

reversed phase.

References

- Giddings, J.C. United Separation Science;

John Wiley & Sons, Inc.: New York,

1991; Chap 12; pp 269–89.

- Mazzeo, J.R.; Neue, U.D.; Kile, M.; Plumb, R.S.

Advancing LC performance with smaller particles and

higher pressure. Anal. Chem. A-pages 2005, 77(23),

460A–7A.

Dr. Huang is CTO, and Ms. McKay is Director of Marketing,

Sepax Technologies, Delaware Technology Park, 5-100

Innovation Way, Newark, DE 19711, U.S.A.; tel.: 302-366-1101; fax: 302-366-1151; e-mail: [email protected].