Chiral molecules continue to drive

growth across a number of industries as

new chemistries, active ingredients, and

products are developed and commercialized.

These industries include pharmaceuticals,

fine chemicals and intermediates,

agrichemicals, and flavors and

fragrances, as well as emerging nutraceutical

and cosmeceutical areas. Due to significant

benefits provided by single-enantiomer

therapeutics and by FDA

requirements, the pharmaceutical industry

in particular has been actively driving

chiral chemistry and technology.

But for all the advantages of chiral compounds,

isolating and purifying them

has remained a difficult, inefficient, and

costly proposition. The technology discussed

here approaches chiral separations

in a radically different way. A new

class of “smart” nano structured materials

have been developed that are highly

effective at separating a broad spectrum

of chiral chemical compounds. This

technology, called EnantioSelective

Polymer™ (ESP™, Evolved Nanomaterial Sciences [ENS], Cambridge,

MA), comprises a suite of novel chiral-selective

materials that can be used in a

variety of industry formats to deliver

chiral separation solutions.

Chiral drugs are one of the fastest-growing

categories of pharmaceuticals. Each

molecule of a chiral drug has a mirror

image. These mirror image molecules, or

enantiomers, are identical in terms of their

chemical structure and physical properties.

While enantiomers can be very hard

to distinguish using chemistry, they can

have very different biological effects, since

the physiological environment is also predominantly

chiral. A chiral drug containing

a mixture of enantiomers may contain

two or more distinct biological ingredients,

each with different biological activities.

This can cause problems with dosing,

lower effectiveness for the chiral drug,

unpredictable pharmacokinetics, or harmful

side effects. For some chiral drugs to be

effective, the mirror image isomer must be

eliminated. Since the enantiomers are

chemically identical, and differ only in

their three-dimensional geometry, selectively

eliminating the undesirable enantiomers

can be very challenging.

Several different conventional avenues

exist to separate enantiomers from a chiral

mixture. Chiral crystallization methods,

including diastereomeric crystallization,

have been around for decades, but method

development is tedious and success is

often “hit or miss.” On the other hand,

chiral chromatography has a higher rate of

success and is growing in popularity.

The difficulties that exist in chiral separations

have spurred a continued interest in

chiral-selective materials that can be

used as stationary phases. Most of the

current chiral materials select for a particular

enantiomer by weakly binding it to

another chiral molecule that is immobilized

on a support within a column. The

chiral molecule, or selector, plus the support,

make up the chromatographic stationary

phase. Different enantiomers are

retained by the stationary phase with different

kinetic time scales, resulting in a

separation. In most cases, the stationary

phase incorporates a large, complex

molecule that can stick to the analyte

enantiomers at multiple points, leading

to chiral selectivity. In other cases, a

folded protein is stuck to the support, and

analytes are captured in the chiral-shaped

pockets of the protein and are

held through hydrogen bonds and other

complexation interactions. Still other

stationary phases rely on beads comprised

entirely of polymers of chiral-selective

molecules, eliminating the need for a

support. All of these approaches rely on a

set of chemical interactions and binding

events to detect the difference between

chiral enantiomers.

EnantioSelective Polymer uses nanotechnology

to directly sense the

three-dimensional chiral geometry of

a molecule by using physical interactions

rather than chemical binding.

The phenomenon is somewhat analogous

to the shape effects observed in

chiral-imprinted polymers, where chiral

molecules in a polymer are dissolved

away, leaving chirally shaped cavities that can select for enantiomers.

Polymer imprinting does not

work well in the absence of binding

interactions, because the shape of the

polymer molecules includes nonchiral

voids or free volume that “washes out”

the imprinted shape recognition. By

using nanoscale engineering techniques,

the company has created a

nanostructured polymer that realizes

the true capability of a physical, “chirally

imprinted” approach. ESP incorporates

a very large number of interconnected

chiral voids. The walls of

the voids are very dense, preventing

the polymer free volume from degrading

the chiral selectivity of the chiral

voids. Interconnecting the voids

makes much more of the material

accessible to analyte molecules. ESP

medium has an ultrahigh interior surface

area comprising minute channels

larger than the size of a large

molecule. The channels are tightly

packed with chiral molecular chains

that protrude like dense brushes. Diffusing

molecules are forced to interact

with these brushes because the interstices

are too small to allow any other

pathway through the material. The

chiral brush and chiral shapes of the

channels select for the enantiomers.

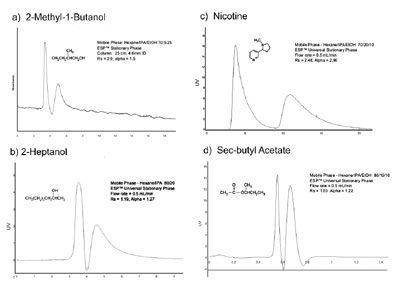

Figure 1 - Using ESP technology, the same stationary phase and identical column can separate

enantiomers of two alcohols (a and b), an alkaloid (c) that causes adsorption problems in conventional

HPLC media, and a small acetate (d). Other compound classes such as fatty chain molecules,

acids, and amines have also been separated using the same stationary phase. Small molecules such as

the acetates and alcohols shown (a, b, and d) often present challenges for chromatographic separation.

In contrast to chiral materials that select

for specific molecules or classes of

molecules, ESP has a broadly selective

spectrum. For example, the identical

ESP-packed HPLC column can separate

chiral alcohols, free amines, chiral acids,

terpenes, alkaloids, and amino acid

derivatives, as illustrated in Figure 1. A

number of compounds within these

classes, as well as entire classes such as

small alcohols and hydrocarbons, have

proven very difficult to separate employing

conventional HPLC column technology.

These compounds and compound

classes can be successfully

resolved with ESP, and are represented

in Figure 1. Several HPLC traces, all

using the identical column without

repacking or a change of stationary

phase, are shown in the figure. It is

important to note that the solvents used

for ESP HPLC separations are mild and

environmentally friendly: typically,

ethanol, isopropanol, and hexane.

In addition to chromatographic separations,

the polymer can be used as

a batch sorbent or as a chiral molecular

sieve. This characteristic is

unusual and extremely powerful;

ESP is indeed a “smart” material and

allows for different separation techniques

to be utilized in order to

obtain a pure enantiomer. The same

material used in a columnlike device

can also be used as a sorbent. In a

number of cases, the polymer has

been used to achieve high enantiomeric

excess (EE) in a single

batch sorbent step using a breathtakingly

simple approach. The enantiomeric

mixture is poured into a

container as a neat liquid or greater

than 5 wt % solution. ESP with a

150–250 μm particle size is added to

the jar. The ratio of ESP used to

undiluted enantiomers ranges from

1:1 to 5:1 by weight. Once the powdered

ESP has been added to the

container holding the enantiomers

(as neat liquid or a reasonably concentrated

solution), the container is

sealed and agitated for roughly 3–5

min. The ESP is filtered off, leaving

predominantly one enantiomer

behind. To avoid confusion with the

theoretical plates in a chromatography

column, the company refers to

this procedure as a single sorbent

stage. In many cases, greater than

95% EE can be attained in one to

five sorbent stages.

This type of simple, highly scaleable

separation has been demonstrated

for phellandrene, nicotine, several

amino acids and their derivatives,

lactic and malic acid, and a number

of terpenes. The terpenes make a

very useful demonstration because

chiral compounds such as limonene

are inexpensive, not dangerous, and

have commercially available enantiomers

for comparison. In a typical

demonstration, observers are invited

to smell the racemate, which is subsequently

added to two vials of ESP.

One ESP has been designed to

exclude the (+) enantiomers; the

other excludes the (–) enantiomers.

Once the racemate has been added

to the two vials containing the two

ESP types, the vial contents are

mixed by tapping. Observers are

then invited to smell the individual

enantiomers. Typically, a high EE,

greater than 70%, is required to

begin to distinguish enantiomers of

a fragrance. A distinct difference

requires a higher EE. In order to perform

a successful smell test demonstration,

the liquids must also be

added neat, since solvents would

interfere with the enantiomers’ individual

fragrances. A high loading of

neat racemate is also required in

order to wet the ESP enough to

allow mixing. This simple demonstration

establishes the enantio

selective power, speed, and capacity

of this technology.

The manufacturer is applying this

technology to deliver novel tools

for the analytical, synthetic, or process

chemist working with chiral

compounds in a variety of applications,

across many industries. The

ESP suite of technologies provides

breakthrough performance addressing

the many challenges posed by

chiral compounds.

Dr. Valluzzi is Chief Scientific Officer, and Dr.

Chaloner-Gill is V.P. Chromatography,

Evolved Nanomaterial Sciences (ENS),

675 Massachusetts Ave., 14th floor, Cambridge,

MA 02139-3309, U.S.A.; tel.: 617-441-5107; fax: 617-902-2700; e-mail: [email protected].