The extraction of organics from water

is fundamental in environmental,

pharmaceutical, process, food, forensic,

and other laboratories. Nearly all laboratories

that perform organic analyses are

equipped with a battery of separatory funnel (SF) and/or continuous liquid-liquid

extractors (CLLEs) to conduct liquid-liquid

extraction. For environmental laboratories

that conduct liquid-liquid extractions in

high volume on a routine basis, this task

can be a critical element, often a bottleneck

of a laboratory operation. The U.S. EPA

imposes a seven-day holding time on water

sample preparations, imparting a significant

burden on extraction technicians, especially

when there are so often delays in getting

the samples from the field to the laboratory.

If holding times are not met, analysis

results are invalid and the laboratories are

commonly charged with the responsibility

to resample.

Laboratories equipped to do either CLLE

or SF liquid-liquid extractions (for the

environmental laboratory, most commonly

Method 3510C or Method 3520C1) choose

one or the other by considering the advantages

and disadvantages of each. An assessment

is made of available labor and capacity

to extract the number of samples on hand,

meet holding time requirements and data

quality objectives, as well as turnaround

time commitments. SFs are used primarily

because a few sample preparations can be

completed within several hours. However,

SF extraction is extremely labor intensive

and often fraught with problems of precision

and accuracy. Emulsions, rendering the

phase separation difficult and sometimes

impossible, are too frequently observed.

Extraction recovery can be inherently low

for some species. CLLEs are costly and slow,

difficult to clean, readily broken, and subject

to drip rate variation, but require much

less labor. For the extraction of herbicides

from water using a lighter-than-water solvent,

the use of CLLE is precluded, leaving

no choice. The especially cumbersome herbicide

method, with its extra steps, was an

additional driving force behind the development

of the technique described here,

so-named bottle liquid-liquid

extraction

(BLLE, or "Billie").

A simple concept in which water, in original

sample bottles received directly from

the field, is mixed with solvent and turned

at a slow rate was explored and found to be

markedly effective, eliminating the many

problems associated with both SF and

CLLE. The advantages of this new method

are readily recognized by organic analysts

who perform high-volume liquid-liquid

extractions on a routine basis. Most notable

benefits are striking simplicity and economy;

radical reduction of labor, solvent,

and solvent waste; ability to prepare a large

number of samples at once; as well as freedom

from emulsions. Extraction times can

be significantly reduced while precision and

overall quality are improved. There is no

glassware to clean, no elaborate equipment

needed, and virtually no labor required.

The use of chlorinated solvents and other

expensive supplies is sharply curtailed (a "green" technique).

Laboratory control sample (fortified

blank) efficiencies for nearly 200 of

the most important environmentally

regulated semivolatile organic analytes

including herbicides, pesticides,

Method 6252 components, and Appendix

IX3 Method 8270C target analytes

were examined and compared to those

obtained using conventional SF or CLLE

techniques. While the study focuses on

species of environmental interest, extraction

efficiencies for a host of related

chemical species can be readily gleaned.

Also presented, an outcome of hundreds

of studies conducted to validate this

procedure, are little known but distinct

recovery patterns and trends observed

among SF, CLLE, and BLLE, which will

help analysts to improve data quality.

The dramatic effects of starting the semivolatile

extraction at an acidic pH as

opposed to base first are elucidated.

Experimental

Early experiments were conducted by rotating

bottles on two ordinary barbecue rotisseries

spaced a few inches apart mounted on

a wooden substrate. Two-inch sections of

rubber hose were cut and slid over square

rotisserie rods to create a smooth, rotating

surface. Clear, wide-mouth 1-L glass jars

were filled approx. 90% full with tap water

and fortified with several drops of a 0.1%

solution of methyl yellow (p-dimethylaminoazobenzene)

in methanol, followed

by a few drops of 1:1 sulfuric acid. (Methyl

yellow, an Appendix IX target analyte, yellow

in color in basic water and bright red in

acidic conditions, served as a visual indicator

of extraction efficiency.) Forty milliliters of

methylene chloride (DCM) was then added

along with 10 g of rock salt. The jar was

placed horizontally on the rotisserie rack and

turned at approx. 3 rpm for 22 hr. After the

22-hr period, the water layer was completely

clear and the DCM layer was bright yellow.

The experiment was repeated, altering the

initial pH to basic conditions. After 22 hr, the DCM layer was observed to be bright

yellow, while the water layer retained a

yellow tinge.

Encouraged by this crude initial study,

more elaborate experiments were

designed, fortifying deionized, charcoal-filtered

water in 1-L bottles with 50 µg of

a 76-component

mixture of semivolatile

organics (Mega-Mix, catalog no. 31850,

Restek Corp., Bellefonte, PA) containing

acid, neutral, and basic extractables. Traditional

8270C surrogates were also added at

levels customary for laboratories following

environmental procedures. The pH was

brought down to <2 and 40 mL DCM was

added. Following a 22-hr turn at 3 rpm,

the bottle contents were transferred to a

2-L separatory funnel and the DCM was

collected. The water layer was returned to

the bottle, the pH readjusted to >12, and

a second 22-hr turn was performed. The

combined acid/neutral and basic extracts

were concentrated to 1 mL using a Turbovap

apparatus (Zymark Corp., Hopkinton,

MA) prior to analysis by the conventional

environmental 8270C method. All

components were recovered, most with

75% or greater recovery. Phenol, pyridine,

and N-nitrosodimethylamine were low,

however, recovering only at about the

10% level.

Additional studies were undertaken to

improve the recovery of the phenol and

amines. The ionic strength of the water

was increased by adding sodium chloride,

and the effect of intermixing diethyl

ether and other solvents with the DCM

was explored. Extracting with a 60/40-mL

mix of DCM/diethyl ether in place of pure

DCM was found to markedly enhance the

recovery for phenol. Adding sodium chloride

to the water (250 g per 1000 mL) significantly

improved the recovery for the

pyridine and other amines.

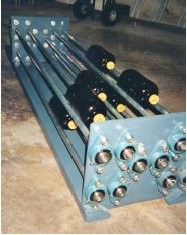

Figure 1 - Photograph of prototype BLLE bottle rotation device.

A heavy-duty turning apparatus was constructed using five sets of 6-ft-long galvanized rods mounted on a rack driven by an electric motor, sprockets, and chain (Figure 1). The device was engineered to turn at triple the earlier experiment rate (12 rpm) as well as to enable 30 1-L bottles to be spun at once. With this apparatus, scores of additional experiments were conducted over years of time to examine the effects of the faster spin, varied durations of spin, alternate mixtures of salt, ether, as well as reversing the extractions by initializing with base rather than acid (Method 625). A vented stopcock bottle cap adapter was designed (Figure 2) to allow the solvent to be removed directly from the bottle, thereby eliminating the need to transfer to a separatory funnel.

Figure 2 - Photograph of bottle cap attachment enabling phase separations to be conducted directly in bottles.

Using the new rotisserie, the following procedures were optimized and are offered here for use:

Procedure A: DCM/ether—Generally semivolatile acid and base-neutral

extractables (Environmental Methods 8270 and 625, specifically)

Step 1: Remove the sample bottle from refrigerated storage and allow to equilibrate to room temperature.

Step 2: Shake the bottle briefly to homogenize the sample. Discard up

to 250 mL and mark the water level meniscus on the bottle for subsequent

accurate volume measurement.

Step 3: Fortify the sample with surrogates and quality control (QC) samples with appropriate solutions. Shake to mix.

Step

4: Adjust the pH of the sample with approx. 3 mL of 12N sulfuric acid.

Check that pH is ≤2 with wide-range pH paper. (A lesser amount of a

stronger acid solution may be substituted.)

Step 5: Add 100 mL of a

60/40 mix of DCM/diethyl ether (BHT-preserved ethyl ether used for this

study; methanol-preserved likely as good).

Step 6: Cap bottle, place

horizontally on rotation rack, and spin for 12 hr at 12 rpm. (Because

the spinning is gentle, there is no pressure buildup, and venting is not

necessary.)

Step 7: Attach an adapter and stopcock to the bottle or

transfer the bottle contents to a conventional separatory funnel to

effect phase separation. Discharge the DCM/ether layer (heavier than

water) into a 200-mL bottle. Add approx. 10 g of sodium sulfate to the

extract and mix.

Step 8: If using a separatory funnel, return the

water to the original bottle and readjust the pH of the water to ≥12

(check with pH paper) using approx. 9 mL of 6N NaOH or a smaller

quantity of 10N NaOH.

Step 9: Add 80 mL of a 50/30 DCM/ethyl ether mix and return to rotisserie for a second 12-hr period.

Step

10: Reattach an adapter and stopcock to the bottle or transfer the

bottle contents to a separatory funnel to effect phase separation.

Combine the DCM/ether layer with the initial DCM/ether extract.

Step

11: Allow the extract to remain in contact with sodium sulfate for at

least 2 hr, mixing periodically. If the sodium sulfate forms clumps, add

additional sodium sulfate until it remains free-flowing. (Adding sodium

sulfate directly to the extract in place of a common practice of

pouring the extract through a funnel or column of sodium sulfate serves

several purposes. The sodium sulfate remains in contact with the extract

for longer periods of time, the successful removal of water is visibly

indicated by an absence of clumps, and much less sodium sulfate is

required.)

Step 12: Drain the extract through a glass fiber filter

and concentrate the extract using conventional evaporative techniques.

Submit for analysis.

Step 13: Recharge the original bottle with tap

water to the original mark and pour into a 1000-mL volumetric flask to

record the exact volume extracted.

Procedure B: Hybrid—Generally semivolatile

acid and base-neutral extractables

(Environmental Methods 8270

and 625, specifically)

Steps 1-7: Identical to Procedure A

Step 8: Returning the water to the original

bottle, add 190 g of sodium chloride and

shake to dissolve.

Step 9: Readjust the pH of the water to ≥12 (check with pH paper) using approx.9 mL of 6N NaOH or a smaller quantity of

10N NaOH.

Step 10: Add 80 mL of DCM and return to

rotisserie for a second 12-hr period.

Steps 11-14: Identical to steps 10-13 of

Procedure A.

Procedure C: Herbicides (Environmental

Methods 8151 and 615 including hydrolysis step)

Step 1: Remove the sample bottle from

refrigerated storage and allow to equilibrate

to room temperature.

Step 2: Shake the bottle briefly to homogenize

the sample. Discard approx. 250 mL

and mark the water level for later measurement.

Step 3: Fortify the sample with surrogate

and batch QC samples with appropriate

solutions.

Step 4: Add 190 g of sodium chloride and

shake to dissolve.

Step 5: Adjust the pH of the sample with

14 mL of 6N NaOH. (Check that pH is =12 with wide-range pH paper.)

Step 6: Cap bottle, place on rotation rack,

and spin for 2 hr at 12 rpm.

Step 7: Add 100 mL DCM to the water in

the bottle and turn for an additional 4 hr.

Step 8: Attach an adapter and stopcock to

the bottle or transfer the bottle contents to

a separatory funnel to effect phase separation.

Discard the DCM layer and return

the water layer to the original bottle.

Readjust the pH of the water to =2 (check

with pH paper) using approx. 14 mL of

12N sulfuric acid.

Step 9: Add 140 mL of diethyl ether

(BHT-preserved required as opposed to

methanol-preserved to avoid quenching

subsequent methylation) and return to the

rotisserie for a 12-hr turn.

Step 10: Reattach an adapter and stopcock

to the bottle or transfer the bottle contents

to a separatory funnel to effect phase separation.

Collect the ether layer (top layer) in

an acid-washed 250-mL bottle containing

approx. 10 g of acidified sodium sulfate.

Step 11: Returning the water to the original

bottle, add an additional 100 mL of

diethyl ether and spin for an additional

12-hr period.

Step 12: Reattach an adapter and stopcock

to the bottle or transfer the bottle contents

to a conventional separatory funnel

to effect phase separation. Add the ether

layer to the original ether extract in the

250-mL bottle containing sodium sulfate.

Step 13: Allow the extract to remain in

contact with sodium sulfate for at least 2

hr, mixing periodically. If the sodium sulfate

forms clumps, add additional sodium

sulfate until it remains free-flowing.

Step 14: Concentrate and derivatize

the extract conventionally and submit

for analysis.

Step 15: Recharge the bottle with tap

water to the original mark and measure the

sample volume using a 1000-mL volumetric

flask.

Results and discussion

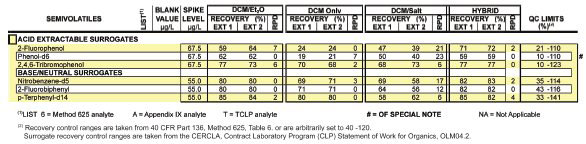

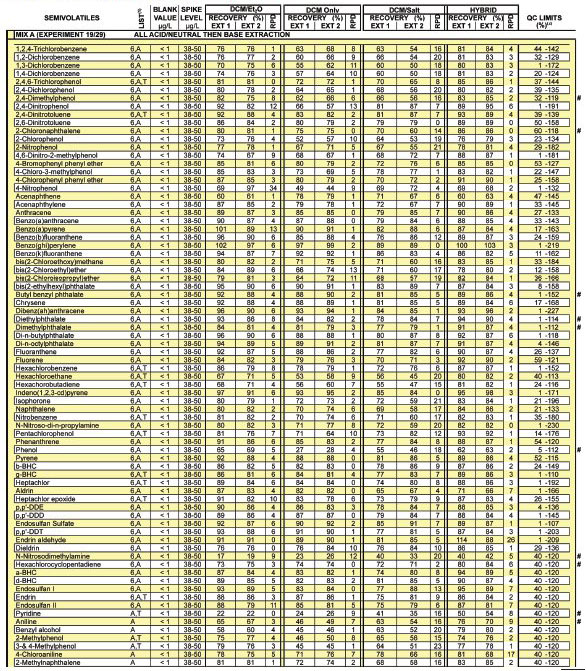

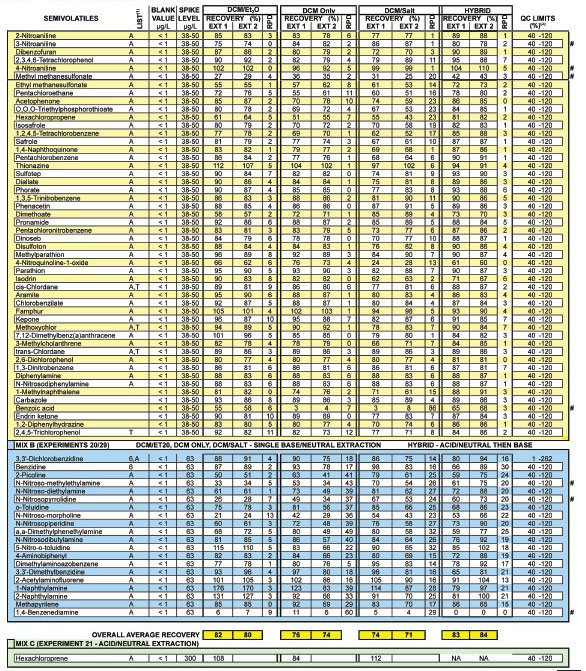

Tables 1-3 summarize dozens of laboratory

control sample and method blank analyses.

Control matrices of purified water were

fortified with a methanolic mix of compounds

prior to pH change and solvent

addition. Under the column header "List,"

analytes associated with Method 625, the

Appendix IX Groundwater Monitoring

List, or the Toxicity Characteristic Leaching

Procedure (TCLP) are encoded with

the character 6, A, or T, respectively. In

each table, applicable QC limits obtained

from Method 625 are provided as a frame

of reference. Recovery limits for those

compounds not associated with Method

625 are arbitrarily set to 40-120. Surrogate

recovery limits are those established by

the U.S. EPA Contract Laboratory Program

(CLP) for semivolatile organics. A

composite of the results for a number of

associated method blanks is provided. The

pound sign (#) is used to call attention to

analytes of special interest.

Table 1 - Bottle extraction: Replicate results of four techniques

Table 1 - Bottle extraction: Replicate results of four techniques continued

Table 1 - Bottle extraction: Replicate results of four techniques continued