For more than 30 years, 2-D electrophoresis has been

used by researchers around the globe to separate proteins

by charge and then by size. Two-dimensional electrophoresis has become a widely used technique

in the field of proteomics for the study of protein

expression and to identify proteins in complex mixtures.

Two-dimensional electrophoresis is the separation

of a protein sample by two different electrophoretic

methods. The current methodology consists

of isoelectric focusing (IEF) separation of proteins

in gel strips based on the proteins’ isoelectric point

(pI) under denaturing and reduced conditions (first

dimension) followed by separation in a slab gel based

on protein mass (second dimension). The combined

technique resolves proteins into spots. Proteins are

detected either by prelabeling the proteins or by

staining the gel post electrophoresis. The gels are

imaged and quantified to look for differences in the

resulting 2-D patterns, or the individual protein spots

can be excised from the gel and identified using mass spectrometry or amino acid sequencing.

Improvements in the IEF gel matrix using immobilized

pH gradients (IPG) have led to more stable and

more reproducible pI separations for the first dimension.

The first-dimension separation is performed in

ultrathin, low-percentage acrylamide gels that are

cast onto a polyester backing for easier handling.

The gels are cast as gradient gels with a pH gradient

being formed by the use of acrylamido buffers, such

as Immobilines® (GE Healthcare, Piscataway, NJ),

covalently bound within the acrylamide matrix. The

gels are shipped dry and need to be hydrated with

buffers, sometimes including the sample, before use.

Each strip is used to separate one protein sample.

Voltage must be applied to the hydrated gel strip and

the separation occurs for a recommended number of

volt-hours (Vhrs). In the past, this was determined

simply by multiplying the voltage by the number of

hours that voltage is applied. Today, most instruments

include a counter to record the voltage over

time and calculate the accumulated Vhrs.

Originally, separations of proteins using IPG

strips were carried out on flat-bed systems.

External power supplies were used to apply voltages

up to 5000 V, and separation temperature

was provided and controlled by external chiller

units. In the 1990s, instruments were introduced

to combine and consolidate the power

supply and cooling into a single, integrated

unit; these units allowed for higher voltages up

to 10,000 V. Little has changed in instrument

design over the past 10 years. A recent development,

however, the Hoefer IEF100 isoelectric

focusing unit (Hoefer Inc., Holliston, MA)

(Figure 1), provides a number of features and

enhancements, including higher voltage for

sharper focusing, constant wattage control to

help reduce heat generation, simplified programming

for ease of use, individual strip monitoring

for documentation of the IEF separation,

enhanced temperature control, and a graphical

user interface for quick visual display of the

voltage profile and current generated on each

sample strip. The key benefits are better feedback

on individual sample performance, visual

display of each strip’s data profile, and faster

run times for IPG strips that require many total

Vhrs to focus.

Figure 1 - Hoefer IEF100 isoelectric focusing unit.

The instrument used for the first-dimension

IEF must be capable of high voltages for high

resolution of proteins. Based on the formulas of

Rilbe in 1973, the resolution of IEF is dependent

on the square root of the electrical field.1,2 The

higher the field strength applied, the higher the

resolution. The Hoefer IEF100 offers 12,000-V

output, the highest voltage available from any

commercial product. In addition, each IPG strip

manufacturer offers suggestions for the number

of Vhrs required for good focusing within its IPG

strip. The total Vhrs required varies depending

on the pH range and the length of the IPG strip.

Volt-hour focusing values of 100,000 Vhrs are

not uncommon, and newer IEF instruments utilize

very high voltages to speed focusing times.

During the final focusing steps of the IEF separation,

a higher voltage applied will accumulate

the required Vhrs in a shorter time period, something

easily accomplished with the Hoefer IEF100.

The first step in generating high-quality 2-D results

is good sample preparation. Under native conditions,

proteins may have limited solubility. To maximize

the solubility of a protein mixture, chaotropes such

as urea and thiourea, and nonionic detergents such

as Triton X-100 (The Dow Chemical Co., Midland,

MI) or zwitterionic detergents such as CHAPS

(3-[(3-cholamidopropyl)dimethylammonio]-1-propanesulfonate))

are used during IPG strip hydration

and during sample preparation. Reductants are also

added to reduce the disulfide bonds and unfold the

proteins. Some care must be taken in sample preparation

to reduce the quantity of compounds that

contribute charge or conductivity to the IPG strip

matrix. Samples that contain high concentrations

of salts have higher conductivity and may prevent

the strips from reaching their desired maximum voltages.

This higher conductivity slows down the focusing

times and can lead to the strips burning if not

carefully controlled by the limits of the IEF device.

Typically, low power is used at the beginning of the

run with increasing voltage applied over time. This

can help by slowly migrating samples to their pIs,

minimizing the heat generated at the beginning of

the run, followed by a high-voltage phase to drive

the proteins into sharp pI zones. Fully programmable

instruments such as the Hoefer IEF100 allow multiple

steps to be programmed to gradually increase the

applied voltage over time for increased flexibility.

Programmability enables the unit to change between

phases without user intervention and reduces the

risk of burning the strips.

The Hoefer IEF100 permits control of power to the

IPG strip by setting a constant wattage for some or

all of the steps of a given protocol. This helps to control

the current and voltage applied to the sample

and prevents overheating. For example, in a simplified

two-step protocol, a low wattage step is used to

initiate salt and protein migration. As proteins and

ions focus into zones, ion movement slows down,

and the conductivity of the strip decreases. As the

current decreases, higher voltages can be applied to

the strips. By controlling the wattage, the heat generated

during electrophoresis is also controlled.

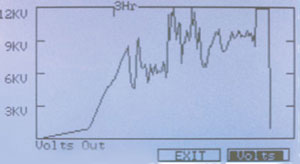

Figure 2 - Hoefer IEF100 graphical display of the total

voltage applied to the IPG strips.

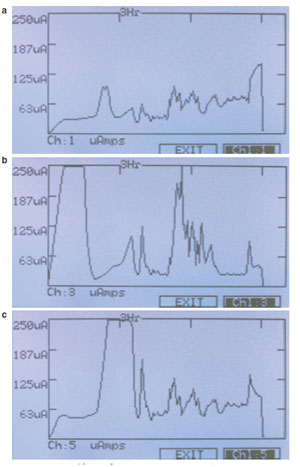

Figure 3 - a) Hoefer IEF100 graphical display μA current generated

of sample extract. b) Hoefer IEF100 graphical display μA current

generated of sample extract including 25 mM NaCl (salt). Note the high

current at the beginning of the run and spikes later in the run as the strip

begins to burn. c) Hoefer IEF100 graphical display μA current generated

of sample extract including 50 mM Tris. Note the higher current later in

the run as the voltage is increased. Overall these strips have higher conductivity

than those without Tris.

The Hoefer IEF100 has the ability to monitor each

individual IPG strip and show both numerically and

graphically the individual current of each strip. The

usefulness of this feature is shown in the examples

of the graphical display and resulting 2-D gels for three IPG strips separated in the Hoefer IEF100

focusing unit. Figure 2 shows the total voltage

applied to all the strips being focused. Figures

3a–c display the current generated in three IPG

strips. Figure 3a shows the current profile of a

24-cm, 3-10NL (nonlinear pH gradient) IPG

strip with ~37 mg Escherichia coli extract in standard

8 M urea, 2% CHAPS, 0.05% Pharmalyte

buffer (GE Healthcare). Figure 3b is an identical

strip, but with 25 mM salt (sodium chloride)

included in the buffer. Figure 3c is an identical

strip, but with 50 mM Tris included in the buffer.

It is apparent even before completing the

experiment that the conductivity of each strip

is very different. The strips with no additives

give a fairly flat and even current throughout

the run, but strips containing salt and Tris have

large peaks of high current as the run progresses.

By looking at the data and comparing them to

the graphs of other strips or previous runs, the

user may gain insight into sample properties

that can lead to problematic results.

Following focusing, the strips were equilibrated

in 50 mM Tris-Cl pH 8.8, 6 M urea, 30% glycerol,

2% sodium dodecyl sulfate (SDS), and 1%

dithiothreitol, and overlaid onto 12.5% SDS slab

gels. The SDS gels were run in the Hoefer SE900

2nd Dimension Gel system (Hoefer Inc.) for

30 min at 100 V followed by 6 hr at 80 mA per

gel. The gels were silver stained. The gel images

(Figures 4–6) help to demonstrate the problems

of how these ionic compounds interfere with the

final 2-D results. Conventionally, 2-D images are

displayed with the acidic region to the left and

the basic pI region to the right. The SDS second

dimension separated the samples from the top

(highest molecular weight) down to the bottom

(lowest molecular weight).With the addition

of salt (Figure 5), there is a large blank region

toward the basic end (right side) of the 2-D gel

and streaking resulting from the concentration of

proteins just before this salt effect. The addition

of Tris (Figure 6) led to poorly focused spots and

increased horizontal streaking. The user now can

see through the graphical interface that the strips

had variations in their conductive properties,

and can then decide if the run properties need

to be altered to avoid damage to the strip, if the

strip needs to be removed from the focusing run,

or if the sample should be prepared differently in

future sample preparations.

Figure 4 - Silver stain of a 2-D gel result generated using a 24-cm,

3-10NL pH IPG strip with ~37 mg E. coli extract in standard 8 M

urea, 2% CHAPS, 0.05% Pharmalyte buffer.

Figure 5 - Silver stain of a 2-D gel result generated using a 24-cm,

3-10NL pH IPG strip with ~37 mg E. coli extract in standard 8 M

urea, 2% CHAPS, 0.05% Pharmalyte buffer containing 25 mM NaCl.

Note the blank region on the right (basic) end of the IPG strip where salt

interferes with the 2-D pattern. The location of strip burning is also evident

by the yellow streak running vertically down the gel.

Figure 6 - Silver stain of a 2-D gel result generated using a 24-cm,

3-10NL pH IPG strip with ~37 mg E. coli extract in standard 8 M

urea, 2% CHAPS, 0.05% Pharmalyte buffer containing 50 mM Tris.

Note the poor focusing of sample particularly in the acidic (left) side of

the 2-D gel.

Capturing the IPG strip current information in

real time provides feedback to users, enabling

greater control of the separation and therefore

allowing them to make better decisions with

respect to problematic or highly conductive samples.

These highly conductive samples may limit the

maximum voltage or current available for the entire

run. As described by Görg,3 low voltages for extended

periods of time at the beginning of the run can help

to desalt the sample prior to IEF separation. When a

strip is noted as having very high conductivity at the

beginning of the run, the user can modify the protocol

to include a low-voltage desalting phase or remove

the strip from the experiment since the higher conductivity

may limit run parameters. Without proper

salt removal, strips can dry out and burn (see Figure

7). The Hoefer IEF100 can display the erratic behavior

of a burning IPG strip (as shown in Figures 2 and

3b). The ability to monitor each IPG strip individually

provides immediate feedback to the researcher.

This valuable information can be used to advise the

researcher to modify sample preparation or run parameters

and prevent run failure.

Figure 7 - Results of too high a voltage applied to 24-cm

strip containing 25 mM salt. The IPG strip has begun to burn

as can be seen by discoloration and damage to the IPG gel. The

Hoefer IEF100’s graphical interface shows erratic currents as

the conductivity across the damaged area changes and arcing

occurs (Figure 3b).

In some cases, other ionic compounds such as

Tris are included in sample extraction buffers or

added to adjust the pH of the sample preparation.

Smejkal4

notes that these ions can create boundaries

that proteins cannot traverse, restricting them

from achieving true focusing. In the examples

provided with Tris (Figure 3c), the current profile is higher and flatter than the sample without

Tris. In addition, the gel pattern shows disruption.

To avoid the complications of additives, sample

cleanup prior to IEF can be helpful to remove

ionic compounds.

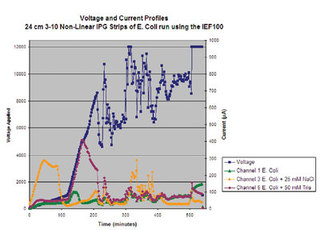

Figure 8 - Chart of parameters recorded during an IEF run using the

Hoefer IEF100. Along the left y axis, the voltage delivered is plotted over

time (x axis). Using the second y axis, the current of the individual IPG

strips is recorded over time. Note that the channel containing salt (Figure

3b, channel 3) has very high conductivity (shown by the very high μA) at

the start of the run, which eventually decreases as the salts and proteins

migrate in the IPG strip. Though this graph shows the parameters for

three of the six channels, the Hoefer IEF100 will record the parameters

for each of the six focusing channels in addition to the Vhrs, W, and temperature

of the run.

In addition to displaying the voltage and current

profile (data) on the liquid crystal display

(LCD) of the Hoefer IEF100, all run parameters

can be sent to an external printer or

captured to a computer (Figure 8). Importing

the data into a spreadsheet program such as

Microsoft® Excel™ can allow users to generate

a graph of all parameters for the run. Thus

they are able to keep a permanent record of

the set parameters and run conditions and

diagnose any problems that may arise during

the focusing.

Temperature control is also very important in

order to achieve reproducible results and prevent

any hot spots from occurring. A protein’s

pI is dependent on the temperature of the separation.

A separation at 20 °C might be very

different from one at 25 °C. Under denaturing

conditions, temperatures over 37 °C may be

detrimental to the protein separation. Heating

of samples in urea solutions can carbamylate

proteins and introduce charge changes,

which is undesirable when protein separation

is based on charge. Localized hot spots can be

generated in zones of high conductivity, such

as areas containing high ion concentration.

Fast dissipation of this heat is important to prevent

overheating in localized regions. The Hoefer

IEF100 is equipped with a Peltier-cooled focusing

bed to accurately and precisely control the temperature

of the separation.

Conclusion

By controlling the temperature, delivering very high

voltages, and collecting data on each individual sample,

the Hoefer IEF100 is an invaluable tool for the

proteomics researcher.

References

- Andrews, A.T. Electrophoresis, 2nd ed.; Oxford University Press: Oxford, U.K., 1986; pp 247–50.

- Righetti, P.G. Immobilized pH Gradients: Theory and Methodology; Elsevier Science Publishers: Amsterdam, The Netherlands, 1990; pp 108–11, 120.

- Görg, A.; Obermaier, C.; Boguth, G.; Harder, A.; Scheibe, B.; Wildgruber, R.; Weiss, W. The current state of two-dimensional electrophoresis with immobilized pH gradients. Electrophoresis Apr 2000, 21(6), 1037–53.

- Smejkal, G.; Robinson, M. Tris interference in IEF and 2-DE. Electrophoresis May 2007, 28(10), 1601–6.

Ms. Laird is Senior Scientist, Hoefer Inc., Holliston, MA,

U.S.A. Mr. Cohen is President, and Mr. Attwood is Director

of Sales and Marketing, Harvard Bioscience, Electrophoresis

Business, 84 October Hill Rd., Holliston, MA

01746, U.S.A.; tel.: 508-893-8999; fax: 508-429-5732;

e-mail: [email protected].