For years, forensic laboratories in the U.S. have struggled to reduce DNA sample processing backlogs and human errors, both of which hinder timely and reliable criminal convictions. A 2011 report from the National Institute of Justice (NIJ) indicated that the U.S. has had more than 100,000 backlogged samples for several years.1 Crime statistics indicate that arrests, identifications, and prosecutions double when genetic information is used to solve a crime. All 50 states now mandate the collection of DNA samples for felony convictions,2 creating more samples than forensic labs can reliably and promptly process.

The industry agrees that improved work flow designs and laboratory infrastructure are needed to reduce processing time, decrease backlogs, and track samples accurately. Pressure from the private and public sectors to solve these problems will remain high, as many high-crime communities are largely unable to access forensic sample analysis tools for crime scene DNA. Meanwhile, many repeat offenders remain on the streets.3

A global problem

Implementing and maintaining a robust, high-quality, nationwide forensic service to support the justice system is challenging. The U.K.’s Forensic Science Service (FSS) is a good example. While it was in operation, the FSS led the world in forensic science research.4 U.S. law enforcement officials studied the FSS in 2010 to learn best practices and understand why the U.K. system had a much faster turnaround time with minimal sample backlogs compared to the U.S.

At the time of the study, the average turnaround time for forensic DNA analysis was three days; some private vendors completed analysis in less than 24 hr‒considerably better than U.S. statistics.4,5 The U.K. system had higher productivity because samples were processed in large, centralized facilities, and these labs had implemented sophisticated laboratory information management systems (LIMS) and automation.4

Because of the challenges that even the best labs face in maintaining a high-quality, reliable forensic work flow, the U.S. Department of Justice (DOJ) has spent more than $500 million since 2004 to improve crime lab work flows, by adding infrastructure and LIMS documentation systems to help reduce the backlog.1,3 Many laboratories have used the DOJ’s grant program to purchase automation and LIMS technologies.

Innovations in forensic lab automation instruments

Figure 1 – Inside view of AutoLys STAR workstation.

Figure 1 – Inside view of AutoLys STAR workstation.Automation can improve work flow by reducing hands-on time and the number of steps within a protocol, thereby increasing laboratory productivity and sample security. By automating DNA isolation‒one of the rate-limiting steps needed to genotype and identify criminals‒labs can eliminate time-consuming pipetting steps and increased traceability, thus eliminating a documentation burden. Automating other steps, such as sample card punching, also boosts productivity and allows laboratories to perform DNA isolation and extraction overnight.

Despite the introduction of several automation tools since 2004, several serious bottlenecks remain. Many labs still need a reliable, fully automated lysis system that maintains chain of evidence for crime scene sample processing. Another need is a fully integrated automated punching and liquid handling system with full sample traceability for direct amplification methods for improved throughput in database crime labs.

Figure 2 – Robotic arm of Microlab easyPunch STAR workstation.

Figure 2 – Robotic arm of Microlab easyPunch STAR workstation.Recent innovations provide automated cell lysis and DNA isolation from samples and sample card punching for blood and saliva extraction. Hamilton Robotics (Reno, NV) has developed three new modules for its Microlab® STAR workstations: the Microlab AutoLys STAR and the Microlab easyPunch STARlet and ID STARlet instruments systems6–8 (see Figures 1 and 2).

Because the benefits of automating a work flow can be offset by the challenges that can arise from implementing automation instruments, all of these systems were designed for forensic and clinical labs that need to scale operations more efficiently within their existing infrastructure.

For example, The Netherlands Forensic Institute (NFI) at The Hague9 is currently validating the Microlab AutoLys STAR system for its work flow. The NFI performs the vast majority of forensic DNA casework in The Netherlands and provides services for global law enforcement agencies. The institute is part of the global surveillance network for chemical, biological, and nuclear terrorism; the illegal wildlife trade; as well as civil and criminal cases. The NFI selected Hamilton because of its ability to provide an automated solution from sample storage to retrieval to upfront processing.9

The NFI found that the AutoLys solution enabled them to automate six steps within the DNA isolation process with minimal impact to extracted DNA quality9,10 (Figure 3). The Hamilton system enabled the automation of key steps, including sample lysis and separating the sample’s raw extract from its carrier buffer. Before the AutoLys solution, these two steps were difficult to automate, always added gaps in traceability, and were considered bottlenecks for NFI and most casework labs.4,10,11

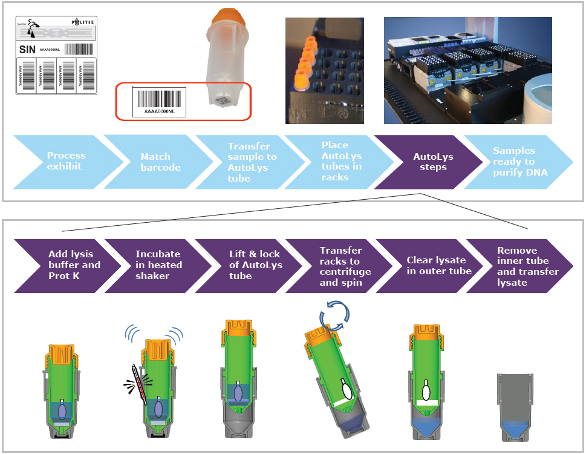

Figure 3 – General sample processing work flow using the AutoLys tubes and AutoLys STAR system. After processing evidence, traces can be directly linked to the AutoLys tube by matching barcodes, enabling full sample traceability during extraction. The integrated filter of the AutoLys tube allows automated separation of lysate from trace carrier. The complete lysis work flow takes place in a single vial. (Reproduced with permission from The Netherlands Forensic Institute, NFI, The Hague.)

Figure 3 – General sample processing work flow using the AutoLys tubes and AutoLys STAR system. After processing evidence, traces can be directly linked to the AutoLys tube by matching barcodes, enabling full sample traceability during extraction. The integrated filter of the AutoLys tube allows automated separation of lysate from trace carrier. The complete lysis work flow takes place in a single vial. (Reproduced with permission from The Netherlands Forensic Institute, NFI, The Hague.) Figure 4 – AutoLys tube assembly.

Figure 4 – AutoLys tube assembly.As shown in Figure 4, central to automating DNA lysis with the Microlab STAR system is the AutoLys tube assembly. The tube is free of DNA, RNA, DNase, and RNase, and has three primary components: an outer tube, an inner filter tube, and a 2-D barcode. The AutoLys tube is basically a spin column that is compatible with the Microlab STAR’s robotic AutoLys channel.6 Preprogrammed software scripts enable the instrumentation to perform the assay steps, which isolate and wash the sample’s DNA in the AutoLys tube.

The software informs Hamilton robotic channel tools to handle the tubes throughout the process, from capping and decapping, to pipetting buffers and other reagents into the sample, throughout the centrifugation steps, and finally transferring the sample lysate into a fresh tube or plate. The system is currently being validated with various forensic sample types including dried blood, saliva, and cigarette butts, and can process up to 96 samples at a time.6

Table 1 – Overall results of Part 1 (initial testing) showing the high efficiency of the AutoLys system compared to manual processing. Average of peak heights from DNA profiles, corrected for dilution factor (1/a) and amount of input in PCR. (Reproduced with permission from The Netherlands Forensic Institute (NFI), The Hague.)

The NFI performed the developmental validation of the AutoLys STAR system prior to its commercial release. As part of its validation process, the NFI evaluated the performance of the AutoLys STAR against manual methods using a “scoring coefficient” that scored samples according to their comparative DNA yield. In this test, the closer the values get to 100%, the closer the automated method is to meeting or exceeding the DNA yield of a manual work flow. The NFI observed that for undiluted blood, diluted blood, and saliva samples, the automated system yields were within a 90–95% of manual methods (see Table 1).10

The investigators from the NFI concluded that the AutoLys STAR, when implemented properly, provides a solution for forensic labs that can overcome the challenges of critical steps in DNA extraction protocols. The automated protocol can provide DNA with equivalent or better yield than manual methods, depending on the sample type. The NFI, using Hamilton instruments, will store up to one million crime scene samples for up to 80 years, as required by government regulations.9,10

Recently, Hamilton Robotics and Life Technologies (Carlsbad, CA) collaborated to develop the Microlab ID STARlet, a new platform with fixed methods that streamlines the entire human identification work flow (DNA extraction, quantitation, normalization, and short tandem repeat (STR) reaction setup. This robotic system exclusively uses Life Technologies’ Applied Biosystems Human Identification kits and consumables to cover the end-to-end forensic work flow, including handling input and output data files between analysis instruments.8

Figure 5 – The easyPunch STARlet system uses Whatman’s FTA® forensics cards for buccal swab samples for STR analysis.

Figure 5 – The easyPunch STARlet system uses Whatman’s FTA® forensics cards for buccal swab samples for STR analysis.For forensic databasing, Hamilton Robotics has developed the easyPunch STARlet platform with Whatman, a GE Healthcare division (Waukesha, WI).7 The easyPunch STARlet system uses Whatman’s FTA® forensics cards for buccal swab samples for STR analysis (see Figure 5). This solution overcomes the challenges of coordinating multiple systems for punching and liquid handling steps by offering one integrated solution. Two special automation modules transport and punch the paper cards, and the STARlet platform includes powerful software for analyzing images and tracking of a variety of sample spots.7,8 Its modular design enables the integration of other devices, such as a centrifuge and plate sealer, thus potentially integrating the entire work flow, including DNA isolation using the ID STARlet workstation.

For smaller labs, the economical Microlab NIMBUS system from Hamilton is a benchtop automated liquid pipetting system that uses similar hardware to its counterparts, and is well suited for PCR sample prep as well as DNA and RNA isolation.12

Conclusion

As the cost of implementing robotic solutions falls, more state and regional laboratories can afford these solutions to mitigate backlogs. This should improve access to genetic services and guard the chain-of-custody for state and local law enforcement agencies, thereby improving conviction rates, exonerating the innocent, and improving public safety.

References

- Nelson, M. Making Sense of DNA Backlogs, 2010—Myth vs. Reality (U.S. Department of Justice National Institute of Justice Special Report); accessed online Oct 2012; https://www.ncjrs.gov/pdffiles1/nij/232197.pdf.

- DNA Saves; accessed online Nov 2012; www.dnasaves.org.

- Mattimore Fuller, V. Accessibility and the backlog: rethinking DNA capacity and capability. Forensic Mag. Apr 25, 2011; accessed online Nov 2012; https://www.forensicmag.com/article/accessibility-and-backlog-rethinking-dna-capability-and-capacity.

- Goulka, J.; Matthies, C. et al. Toward a Comparison of DNA Profiling and Databases in the United States and England (Rand Corporation, 2010), 1–8; accessed online Nov 2012; http://www.rand.org/content/dam/rand/pubs/technical_reports/2010/RAND_TR918.pdf.

- Lakhani, N. CSI Chief condemns forensic cuts. The Independent, Jan 9, 2012; accessed online Dec 2012; http://www.independent.co.uk/news/uk/crime/csi-chief-condemns-forensic-cuts-2179744.html.

- The Hamilton Company, Robotics, Standard Solutions, AutoLys STAR; http://www.hamiltonrobotics.com/hamilton-robotics/standard-solutions/autolys-star/.

- The Hamilton Company, Robotics, Standard Solutions, easyPunch STARlet; http://www.hamiltonrobotics.com/hamilton-robotics/standard-solutions/easypunch-starlet-fta/.

- The Hamilton Company, Robotics, Standard Solutions, Microlab STARlet; http://www.hamiltonrobotics.com/hamilton-robotics/standard-solutions/microlab-id-starlet/.

- The Hamilton Company, “New Hamilton Fully Automated Sample Lysis Solution to be Validated by Netherlands Forensic Institute,” Feb 14, 2012; http://www.evidencemagazine.com/images/Newsletters Feb 2012/HamiltonAutoLysSystem.pdf.

- de Jong, B., Tack, L. et al. Automated lysis and purification of high quality DNA from biological materials for total sample traceability. The Netherlands Forensic Institute, June 2012.

- Kemp, S.; Pinchin, R. Decreasing turnaround time of DNA analysis by improving processes in the laboratory. Int. Lab. India Ed.; accessed online Nov 2012; http://www.thermo.com/eThermo/CMA/PDFs/Various/File_4038.pdf.

- The Hamilton Company, Robotics, Standard Solutions, NIMBUS; http://www.hamiltonrobotics.com/hamilton-robotics/nimbus2/.

Laurent Baron, Bobby Chavli, and Lois Tack are with Hamilton Robotics, 4970 Energy Way, Reno, NV 89502, U.S.A.; tel.: 510-364-2885; e-mail: [email protected]. Annette Summers is with GeneCom Group, San Francisco, CA, U.S.A.