Recent developments in upstream processing of

biomolecules, driven by an increasing demand for

biotherapeutics, have resulted in increased protein

expression levels and larger feed volumes. As the

total amount of protein increases, the capture and

intermediate purification steps in the downstream

process must be able to handle larger volumes with

higher amounts of expressed protein in a fast and

efficient way. This requires separation media with

properties supporting both high flow velocity and

high dynamic binding capacity.

The Capto™ Q is a strong anion exchanger (GE

Healthcare Bio-Sciences AB, Uppsala, Sweden) based

on a highly rigid agarose matrix. It combines high

capacity with high flow rates at low backpressures.

This article describes the capture of green fluorescent

protein (GFP) on Capto Q. Results from

media screening, optimization, scaleup, as well as

scale-up modeling and productivity calculations

are presented. In addition, some general guidelines

on optimizing a capture step when using the anion exchanger are given.

GFP is a 28-kDa protein with a pI of 6.2, in nature

found in the pacific jellyfish AequoreaVictoria. In

this study, recombinant GFP expressed in Escherichiacoli was purified. The goal of the study was to demonstrate

that it is possible to capture 100 kg of product

per 24 hr using Capto Q. As will be shown, the goal

was reached.

Experimental and results

Method development and optimization work was

performed using an ÄKTAexplorer™ system, while

the scaleup was performed using an ÄKTApilot™

system (both from GE Healthcare Bio-Sciences

AB). Since GFP absorbs light specifically at 490

nm, it was easy to follow the protein during process

development and optimization.

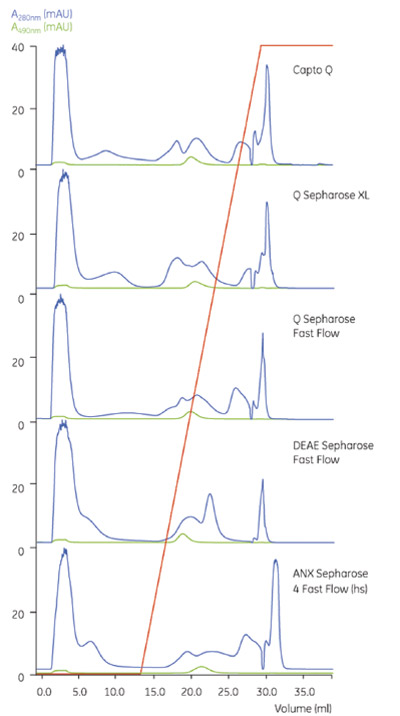

Figure 1 - Screening of media selectivity. From top to bottom:

Capto Q, Q Sepharose XL, Q Sepharose Fast Flow,

DEAE Sepharose Fast Flow, and ANX Sepharose 4 Fast Flow

(hs). Blue curve: A280, green curve: A490 (GFP). (Figures

1–4 © 2006 GE Healthcare Bio-Sciences AB. Reproduced

with kind permission.)

An initial benchmarking of different

anion exchange media (Capto Q, Q

Sepharose™ Fast Flow, Q Sepharose

XL, ANX Sepharose 4 Fast Flow [hs],

and DEAE Sepharose Fast Flow [all

from GE Healthcare Bio-Sciences

AB]) was done at small scale using

prepacked HiTrap™ columns (GE

Healthcare Bio-Sciences AB). Figure

1 shows the result of the screening.

It can be seen that Capto Q gave a

selectivity profile that differed slightly

from the other tested media and it was

decided to use Capto Q for optimization

of the capture step.

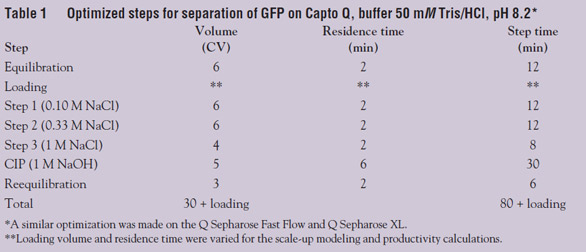

Optimization of the capture step was

performed, determining both optimal pH and conductivity for binding and elution as

well as residence time for optimal productivity. To

save process time and minimize buffer consumption, the process equilibration/reequilibration/wash/elution/cleaning in place (CIP) volumes

were optimized without sacrificing purity and yield.

It was found that the optimal loading buffer was 50

mM Tris/HCl, pH 8.2. Elution was accomplished

by using a step gradient with an increasing amount

of NaCl. Table 1 shows the optimized steps for the

separation. One should be aware that for some

proteins, the dynamic binding capacity on Capto

Q does increase upon increased ionic strength up

to a certain ionic strength, over which it again

decreases. It is therefore recommended that both

loading pH and loading conductivity, between

2 and 15 mS/cm, are optimized with respect to

dynamic binding capacity as well as purity of the

target protein.

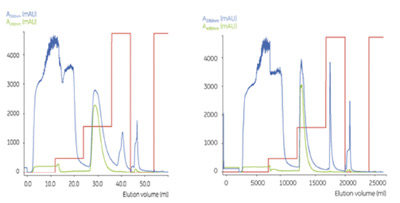

Figure 2 - Capture of GFP on small-scale (2-mL) and pilot-scale (800-mL)

columns. On the small scale, 30 mg, and on the pilot scale, 12 g of GFP were

loaded per run. Note that in the pilot-scale chromatogram, the volume axis includes

the equilibrium step; in the small-scale experiment, the start point is at the start of

sample introduction.

The developed method was used for scaling up

the separation to pilot scale. A 400-fold scaleup

was performed from a Tricorn™ 5/100 column

(GE Healthcare

Bio-Sciences AB) (10-cm bed

height, 2-mL volume) to a FineLINE™ 70 column

(GE Healthcare Bio-Sciences AB) (20-cm bed

height, 800-mL volume), keeping the residence

time constant. Figure 2 shows a comparison of the

results from the two scales. The purification factor

was at both scales approx. 5, and yields in all runs

were above 90%. Analysis by 2-D electrophoresis

showed that the profile of the copurified contaminants

was very similar at the two scales (data not

shown). Scaleup of processes for biopharmaceuticals

requires that the separation profile remain the

same at the different scales. This includes parameters

such as purification factor and yield as well as

clearance of critical impurities like nucleic acids,

host cell proteins, and viruses. Any of these factors

may change when column bed height is altered,

and should thus be validated using the final bed

height. This is of great importance to remember,

since in the early stages of a project there is often

a shortage of material and work is carried out in

columns with lower bed heights than will be used

at the production scale.

Scale-up calculations

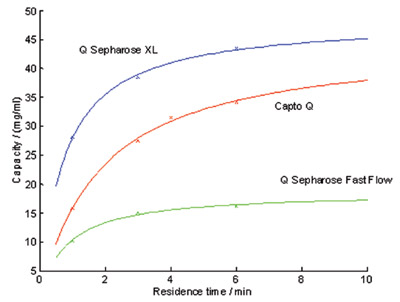

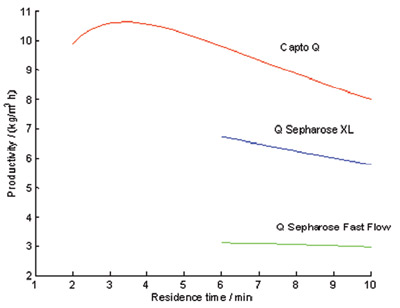

Figure 3 - Dynamic binding capacities for GFP on Capto Q, Q Sepharose XL,

and Q Sepharose Fast Flow as a function of residence time.

Dynamic binding capacities (DBC) for GFP

were determined at different residence times

on Capto Q, Q Sepharose XL, and Q Sepharose

Fast Flow (Figure 3). Based on these results and

the chromatography cycle data of

the three media (parameters used for

Capto Q shown in Table 1), productivity

calculations for each medium

were performed.

Figure 4 - Calculated productivity with Capto Q compared to Q Sepharose XL

and Q Sepharose Fast Flow. Note that Q Sepharose XL and Q Sepharose Fast

Flow do not have the same rigidity as Capto Q; thus there are no values for these

media at the shorter residence times attainable at the 20-cm bed height.

A theoretical scaleup was done to 20-cm bed height by keeping the respective

residence times constant, i.e., operating

Capto and Sepharose (Fast Flow and

XL) resins at 600 cm/hr and 200 cm/hr,

respectively. Exceptions were the loading

step, run at different flow velocities,

and the CIP, which was kept constant

at 30 min. The cycle time when using

Capto Q (1.5 hr) is considerably shorter

compared to when using Q Sepharose

XL or Q Sepharose Fast Flow (3.5 hr).

The columns were loaded to 70% of

DBC (QB 10%) and yield was measured

to be 93.5%. The effect of varying the

loading velocity on resin productivity is

shown in Figure 4. Since Capto Q allows

higher flow velocities to be used, the

developed process can be run at shorter

residence times compared to Q Sepharose

XL or Q Sepharose Fast Flow. Thus,

note that although the DBC is higher

on Q Sepharose XL compared to Capto

Q (Figure 3), the productivity is higher

on Capto Q. The high productivity

achieved on Capto Q stems from both

a high dynamic binding capacity and

the possibility of using high flow velocities,

even at a large scale. As can be seen

from Figure 4, the maximum productivity

achieved on Capto Q is 10.4 kg/m3hr.

This corresponds to the goal of 100 kg of

product per 24 hr in a 400-L column (0.2

× 1.6 [i.d.] m).

Conclusion

A capture step was developed that

gave a high yield of target protein as

well as removal of bulk impurities in less than

2 hr. A 400-fold scaleup was demonstrated.

Recoveries were above 90% at both scales. The

purification factor, approx. 5, indicates that the

majority of contaminants had been removed.

Not only were the recoveries high, but the product

eluted in a small volume (2.6 column volumes

in the FineLINE 70 column), which is

critical for a subsequent chromatography step.

Finally, a short overall process time means

improved product integrity by reducing exposure

time to proteases and other contaminants detrimental

to product quality and yield. Altogether,

the results show that Capto Q is well suited for

use in a capture step.

Ms. Åkerblom and Mr. Bryntesson are Research Engineers,

Dr. Brekkan is a Scientist, and Dr. Eriksson is a Senior Scientist,

GE Healthcare Bio-Sciences AB, Björkgatan 30, SE-

751 84 Uppsala, Sweden; tel.: +46 18 6120539; fax: +46

186121844; e-mail: [email protected].