In the past decade we have seen advances in laboratory

automation and in assays used to assess biological endpoints. At the Southern Research Institute

(Birmingham, AL), these new technologies have

greatly enhanced its high-throughput screening (HTS) capabilities for viral targets in cell-, protein-,

and enzyme-based assays. These technologies can be

leveraged to rapidly screen large compound libraries

to discover new antivirals for previously unrecognized,

emerging pathogens. There has been a dramatic

increase in emerging pathogens, which impact

public health and can result in serious economic

impact at regional or global levels.1,2 Emerging viral

illnesses present a number of unique challenges in

drug discovery efforts, including limited reagents,

access to viral strains, containment, and availability

of trained scientists. In the last decade, resources

have become available for the development of facilities

to study these pathogens, and importantly, for

the development of therapeutics for the treatment

of the diseases they inflict. This article presents the

special issues that must be considered in the creation

of a drug discovery program for these types of

viral pathogens, with examples from the Southern

Research Institute drug discovery research program

in Biosafety Level 2 (BSL2) and Biosafety Level 3

(BSL3) containment.

Special considerations for pathogens

The National Institutes of Health (NIH, Bethesda,

MD) and Centers for Disease Control (CDC,

Atlanta, GA) have three categories for emerging

and biodefense-related pathogens: A, B, and

C.3,4 These pathogens are grouped by the ease

with which they can be spread and the severity

of the disease they cause. For example, many of

the hemorrhagic fever diseases, such as the Ebola

and Machupo viruses, and the bacterium Bacillus

anthracis (anthrax), are placed in Category

A, because they are thought to have the highest

risk and impact in spread and illness. Nipah

virus, influenza, severe acute respiratory distress

syndrome coronavirus (SARS CoV), and hantaviruses

are grouped as Category C agents, and are

considered emerging infectious disease threats.

In addition to the basic research efforts needed

to understand the life cycles of these pathogens

and their effect on human or wildlife hosts, it is

essential that we begin to develop therapeutics for

the treatment of the diseases they inflict. The vast

majority of these agents require specialized containment

laboratories such as BSL3 or 4.5

Several important matters must be considered when

establishing a facility dedicated to the discovery and

development of new therapeutics, i.e., the requirement

for BSL3 or 4 laboratory facilities, regulatory

issues (e.g., Select Agent Rule,6 GLP compliance,

and CDC and USDA permits), personal protective

equipment (PPE), and containment of equipment

as necessary. In addition, the processes for flow of

work among the various laboratories must be thoroughly

reviewed to ensure high-quality results. The Southern Research Institute’s overall approach to

the implementation of HTS for BSL2 and 3 viral

pathogens7,8 is outlined below.

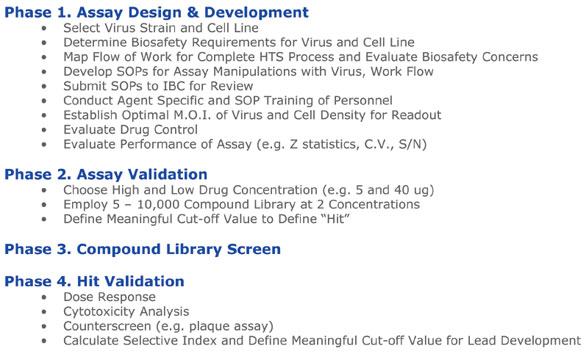

Phase 1: Assay design and development

Figure 1 - Steps undertaken through hit validation. The four phases, with various steps, from assay design and development through

hit validation.

The first HTS assay implemented at Southern

Research was for the SARS CoV.9 The luminescent-based assay measures the inhibition of SARS

CoV-induced cytopathic effect (CPE) in Vero E6

cells. The following section describes the various

steps undertaken through hit validation (Figure

1). The first step in the process was a risk assessment

of the pathogen with respect to its transmissibility

and the type of containment required

within the BSL3. Hence, prior to the development

of the screen, decisions were made on the

type of PPE to be worn by laboratory workers

(Figure 2) and type of containment required

for equipment that might aerosolize virus.

The coronaviruses (order Nidovirales—family

Coronaviridae—genus Coronavirus) are members

of a family of positive-sense RNA viruses that

replicate in the cytoplasm of animal host cells.

They are a diverse group of large, enveloped

viruses that infect many mammalian and avian

species, causing upper respiratory, gastrointestinal,

hepatic, and central nervous system diseases.

It is generally accepted that SARS CoV

is transmitted by close person-to-person contact

through coughing or sneezing, which deposits

respiratory droplets on the mucous membranes

of the mouth, nose, or eyes of persons nearby.

Additionally, transmission can occur through contact with surfaces contaminated with the infectious

droplets.

Figure 2 - A scientist at Southern Research conducts in vitro efficacy

testing of a vaccine candidate to prevent high path Avian influenza

(HPAI) infections. This work is being conducted in the company’s BSL3

laboratory in Birmingham, using both hand screening and robotic screening

measures.

Because SARS CoV is airborne and has the ability to

be transmitted from person to person, it was decided

that those handling the virus would wear positive

air-pressure respirators (PAPRs), full-length Tyvek®

suits (DuPont Co., Wilmington, DE) with a wraparound

gown over the scrubs, double shoe covers, and

double latex gloves (Figure 2). Workers dressed in

the wraparound gown and additional layer of gloves

and shoe covers before entering the HTS laboratory

within the BSL3, and removed them when exiting the HTS laboratory. The liquid handling equipment

that dispenses the virus into drugged plates

was placed in a biosafety cabinet (BSC). However,

the plate reader for reading the endpoints was kept

outside. The plate reader and its plate stacker will

not fit in a BSC, and while there is inherent risk of

plates dropping or becoming jammed in the reader, it

was decided that the PPE and BSL3 would act as sufficient

barriers to any possible accidental exposure.

Once the protective barriers were in place, the next

step in the establishment of the screen was to define

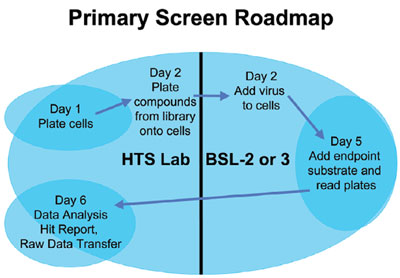

the optimal flow of work (Figure 3). While it would

be advantageous to add chemical compounds to the

screen after virus addition, the problems associated

with maintaining compound libraries in the BSL3

would be formidable. In addition, because of BSL3

regulations, compounds cannot leave the facility

without undergoing a decontamination procedure,

which could alter the integrity of the sample. It was

agreed that storage and aliquoting of compounds

would take place 24 hr after the addition of cells

to multiple-well plates. All of the processes, procedures,

and safety considerations were submitted to

the Institutional Biosafety Committee for review.

Figure 3 - Optimal flow of work.

For the BSL2 virus HTS such as for influenza, the

majority of the safety guidelines above continue to be

followed. The major difference lies solely in the PPE.

In the BSL2 laboratory, gloves, laboratory coats, and

safety goggles are worn. All of the equipment safety

barriers are the same as described for BSL3.

Once approval was met, the actual development and

optimization of the assay and evaluation of the flow

of work outlined was undertaken. Optimization of

the assay requires judicious attention to every detail,

such as the choice of consumables, cell age, growth

conditions, and liquid handler. For example, using an

eight-channel peristaltic pump, Vero E6 cells were

plated in black, clear-bottom, 96-well plates at a

density of 10,000 cells/well in a 50-μL assay medium.

Careful attention needs to be paid to controlling the

humidity of the CO2 incubator, and some brands

appear to do this better than others. The next day,

25 μL of compounds were added to the cells using a

flexible liquid handling system in a biosafety cabinet.

In this case, the BSC was used to protect the cells

from the environment, i.e., keep them in an aseptic

environment. In the Southern Research work flow,

plates are drugged and then hand-carried into the

BSL3 in groups of 50 plates per run. Using more than

50 plates is difficult in the BSL3 environment simply

because of movement logistics. In the BSL2 HTS

virology laboratory, however, up to 125 plates can be

moved effectively, since the constraints of BSL3 are

not present. Plating of the compounds requires about

twice as much time as plating of the virus; thus the flow of work depends on the equipment chosen

for this activity. In all instances, compounds

are plated prior to virus addition.

After incubation for three days, a luminescent

cell viability reagent is added that

measures cellular adenosine triphosphate

(ATP) levels to each well using a laboratory

automation workstation benchmark system.

Recently, the laboratory switched to a system

with a smaller footprint. Smaller footprints

in equipment are of particular advantage

in BSL3, where space is at a premium. For

96-well assay plates, plates are shaken on a

compact benchtop plate shaker, which has

a small footprint as well. For 384-well plates,

the plates are not rocked. Luminescence is

measured using a plate reader. An Ethernet

interface allows direct uploading of the data

into the database and analyses using an integrated

data management software application outside

of the BSL3. Each plate contains negative and

positive controls that are used to fail or pass plates

that have Z-values of less than 0.5.9

Phase 2: Assay validation

As part of the validation for the viral HTS assay,

small compound libraries are used to determine

the reproducibility of the hits and the hit rate. A

“hit” is identified as an active compound that either

activates or inhibits the assay signal above a defined

threshold value from the sample mean signal. A hit

for this assay was considered to be any compound

exhibiting a % CPE inhibition of >50%. The hit

rate can vary depending on the virus.9,10 While

the library in this study was not validated against

a high and low drug concentration, subsequent

studies with other viruses have shown it to be an

important step at this stage of assay validation. For

example, in the validation effort of the assay to discover

small molecules that inhibit the cytopathic

effect exerted by influenza viruses, the laboratory’s

high-throughput cell-based assay was used to screen

16,000 compounds from a commercially available

compound library at a low and high concentration.

10 The hit rate for the compounds screened at

low concentration was 0.02% compared to 0.38%

at the high concentration, for an approximately

19-fold increase in the hit rate. For the SARS CoV

screen, hit rates of 0.01%9 were observed.

A comparison of the screening results from the same

set of compounds assayed on different days is the

most effective way to determine the reproducibility

of the assay. If one relies solely on the control wells

to assess the assay, one may develop a false sense of

confidence in its capabilities. The liquid handling

steps used for the control wells, which are usually

on either end of the plate, often differ from the steps

used for the unknowns in the compound library.

Also, the positive control compounds are usually

limited to one or two mechanisms of action. Reliance

only on data from these compounds may inadvertently

bias one against compounds operating by

different mechanisms.

While two libraries comprising known biologically

active compounds were used for the initial validation,

another rationale for choosing the validation

library is that one can select a subset of compounds

representing the chemical diversity of the larger

compound library. By doing this, the hit rate at a

proposed screening concentration can be estimated,

allowing one to adjust the concentration up or down

for the large screen. A benefit to choosing the validation

set in this way is that when the large library

is screened, the validation compounds are scattered throughout the large screen. This provides an independent

third assay of these compounds that can be

used to assess the quality of the large run.

Another advantage of choosing a large compound

validation set relates to troubleshooting the automation.

Typically, running a few plates at a time is

insufficient to identify problems that are likely to

occur when handling a large number of plates in

one day. The optimized validation set of Southern

Research is 10,000 compounds, or about 10% of the

large library.

Phases 3 and 4: Compound library screen and hit validation

At this stage, the general algorithm for HTS antiviral

screening employs the validated primary cell-based

assay for determining single-dose efficacy with

one or more of the laboratory’s large libraries. This

type of approach has been used successfully to screen

nearly two million compounds. This is followed by a

second, similar cell-based screen for toxicity evaluation

of the compound, which showed 50% or better

activity and dose response (DR) confirmation.

Those compounds with robust SI values are confirmed

in secondary assays (such as a plaque assay).

As an example of the large compound library screen,

100,000 compounds were screened in duplicate from

the 100,000-compound library against SARS CoV.9

The hit rate for this library (compounds that inhibited

CPE by >50%) in a single-dose (SD) format was

determined to be approximately 0.8%.

To screen selected hits from the SD assay, compounds

were confirmed in a DR format. Every HTS

assay has a false positive rate, and hits from the

primary SD screen are only considered potential

positives until that activity is confirmed in a second

DR screen, as mentioned above. Hence, the SD

screen identifies a smaller subset of effective lead

compounds (i.e., hits), which are then run through

one or several secondary assays to define the compound

dose response and/or toxicity. The accuracy

of the primary assay is paramount for identifying hits,

while simultaneously reducing the number of compounds

funneled through the secondary assays and

greatly decreasing the amount of time and resources

required to evaluate lead antiviral compounds. The

criterion for determining compound activity is based

on its selective index (SI50). The compounds with

an SI50 value of <4 are classified as not active, SI50

= 4–9 as slightly active, SI50 = 10–49 as moderately

active, and SI50 >50 as highly active. Following confirmation,

structure–activity relationships are defined

using a cheminformatic approach to identify other

similar molecules that might be available commercially.

Additional parallel chemical synthesis may

be done to generate a group of structurally related

compounds, which are reevaluated with the aforementioned

DR assays and further characterized for

mechanism of action if promising.

Next, an assay is used to determine the point in the

SARS CoV life cycle that the DR hits inhibited. In

effect, this simple screen allows one to ascertain if

the inhibition of the compound was early (entry)

versus late (replication). The laboratory’s biochemical

assays also exploit the high sensitivity of fluorescence detection, or use proximity assay formats with

ultralow background interference.

The development of a panel of biochemical assays

is important for the identification of the mode of

action for each lead candidate. These assays target vital components of the virus life cycle that are necessary

for infection, disruption of host–cell mRNA

translation, transcription, and virus budding. The

targets are often unique to the virus, and similar

activities are not found in the host such as for influenza,

which has neuraminidase, M2 proton channel,

and NS1A RNA binding activities.

Summary

The activities described above give an introduction

to the first phase of activity essential to drug discovery,

and this is clearly just the beginning. Once a hit

has been verified using a combination of cell-based

and biochemical methods, we can move forward to

determine the toxicity and efficacy of the drug in an

animal model. It is after this stage that we will gain

valuable insight into the suitability of the compound

class for lead optimization medicinal chemistry and

follow-up preclinical toxicology testing. It is hoped

that recent advances in infrastructure, new assays,

and HTS procedures will lead to the discovery of

new antiviral drugs for emerging and reemerging

pathogens, those of which we are aware and those

that are yet to come.

References

- Satcher, D. Emerging infections: getting ahead of the curve. Emerg. Inf. Dis. 1995, 1, 1–6.

- King, D.A.; Peckham, C.; Waage, J.K.; Brownlie, J.; Woolhouse, M.E.J. Infectious diseases: preparing for the future. Science2006, 313, 1392–3.

- www.bt.cdc.gov/agent/agentlist-category.asp.

- www3.niaid.nih.gov/biodefense/bandc_priority.htm.

- www.cdc.gov/OD/OHS/biosfty/bmbl4/bmbl4toc.htm.

- www.cdc.gov/od/sap/.

- Peiris, J.S.; Lai, S.T.; Poon, L.L.; Guan, Y.; Yam, L.Y.; Lim, W.; Nicholls, J.; Yee, W.K.; Yan, W.W.; Cheung, M.T.; Cheng, V.C.; Chan, K.H.; Tsang, D.N.; Yung, R.W.; Ng, T.K.; Yuen, K.Y. Coronavirus as a possible cause of severe acute respiratory syndrome. Lancet2003, 361, 1319–25.

- Kuiken, T.; Fouchier, R.A.M.; Schutten, M.; Rimmelzwaan, G.F.; van Amerongen, G.; van Rie, D.; Laman, J.D.; de Jong, T.; van Doornum, G.; Lim, W.; Ee Ling, A.; Chan, P.K.S.; Tam, J.S.; Zambon, M.C.; Gopal, R.; Drosten, C.; van der Werf, S.; Escriou, N.; Manuguerra, J.-C.; Stöhr, K.; Malik Peiris, J.S.; Osterhaus, A.D.M.E. Newly discovered coronavirus as the primary cause of severe acute respiratory syndrome. Lancet2003, 362, 263–70.

- Severson, W.E.; Shindo, N.; Sosa, M.; Fletcher, T.; White, L.; Jonsson, C. Development, validation and optimization of a luminescence-based high throughput screen for inhibitors of Severe Acute Respiratory Syndrome. J. Biomol. Scr. 2007, 12, 33–40.

- Noah, J.; Severson, W.; Noah, D.; Rasmussen, L.; White, E.L.; Jonsson, C.B. A cell based luminescence assay is effective for high throughput screening of potential influenza antivirals. Antiviral Res. 2007, 73, 50–9.

Dr. Jonsson is Program Leader, Emerging Infectious Diseases

Research Program; Ms. White is Manager, High Throughput

Screening Center and Enzymology Laboratory; Dr. Noah is

Research Biologist; Dr. Severson is Research Biologist; and

Dr. Heil is Associate Research Biologist, Emerging Infectious

Diseases Research Program, Southern Research Institute, 2000

9th Ave. S., Birmingham, AL 35205, U.S.A.; tel.: 205-581-2681; fax: 205-581-2093; e-mail: [email protected].