Purge-and-trap (P&T) concentration along with GC analysis is a widely used method for the detection of volatile organic compounds (VOCs). This methodology was developed to achieve the high sensitivity necessary to determine VOCs in drinking water according to U.S. EPA Method 524.2. The U.S. EPA began revising Method 524.2 to possibly permit method flexibility. Occurrence and environmental impact factors were taken into consideration for the current list as well as possible new target analytes. Research is now complete, and the U.S. EPA currently proposes a new revision to Method 524.2. A revised list of analytes consisting of challenging compounds such as iodinated trihalomethanes (ITHMs), fuel oxygenates, and Contaminant Candidate List 3 (CCL-3) volatile organic compounds was proposed in 2008. This newly proposed method will be 524.3, and may include new parameter optimizations not previously permitted in 524.2 as well as the ability to use selective ion monitoring (SIM) analysis for troublesome compounds.

To accommodate the proposed guidelines of U.S. EPA Method 524.3, Teledyne Tekmar (Mason, OH) chose to perform a purge efficiency (PE) evaluation using its latest P&T technology by utilizing the Stratum Purge and Trap Concentrator (PTC). The Stratum PTC is a new-generation and enhanced P&T concentrator recently introduced into the analytical arena. It features U-shaped analytical and condensate traps; proprietary sorbent materials; independently controlled electronic mass flow controller (patent pending); a Siltek-coated (Restek Corp., Bellefonte, PA) sample pathway; and other enhancements, providing improvements over earlier P&T concentrators and demonstrating impressive results for many current U.S. EPA methodologies, including 524.3.

This study was done in conjunction with the U.S. EPA. Overall efficiency (OE) data were provided by the U.S. EPA at the AWBERC facility in Cincinnati, OH. PE data were collected by Teledyne Tekmar using a normalized analysis run consisting of an 11-min purge time and 40-mL/min purge flow for water sample analysis. Both data sets are presented here.

Experimental

Instrument conditions

An Agilent 6890/5973 GC-MS (Agilent Technologies, Palo Alto, CA), Stratum PTC, and SOLATek 72 Multi-Matrix Autosampler (Teledyne Tekmar) were used for the analysis. Results and findings were obtained through the use of a 20 m × 0.18 mm × 1.0 μm RTX-VMS fused-silica capillary column (Restek Corp.). The mass spectrometer detector (MSD) scanned in full-scan mode from 35 to 350 m/z at 5.27 scan/sec.

Data results

Table 1 - Purge efficiency data

A complete list of the newly proposed target analytes was kindly provided by the U.S. EPA. Stock standards were prepared and 25 replicate samples at 20 ppb were analyzed. The mean percent recovery data were generated by taking the average response of all replicate samples (Table 1). The results for this analysis were impressive, with the recovery for all targets analyzed at approximately 90% or higher. RSD values were well below the 10% range.

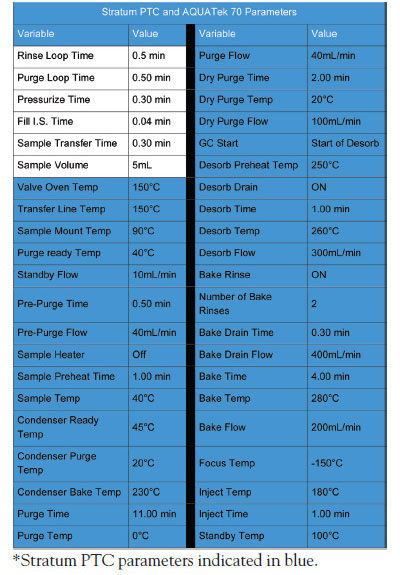

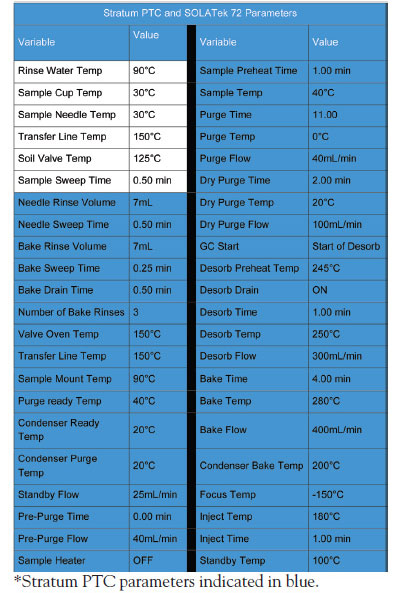

Data collected by the U.S. EPA at the AWBERC facility utilized the Stratum PTC along with the AQUATek 70 liquid autosampler (Teledyne Tekmar). Both the concentrator and autosampler were connected to an Agilent GC-MS system using the same type of analytical column and instrument parameters as those in the studies performed at Tekmar. Instrument parameters for the Stratum PTC and AQUATek 70 and SOLATek 72 are presented in Tables 2 and 3, respectively.

Table 2 - Stratum PTC/AQUATek 70

parameters*

Table 3 - Stratum PTC/SOLATek 72

parameters*

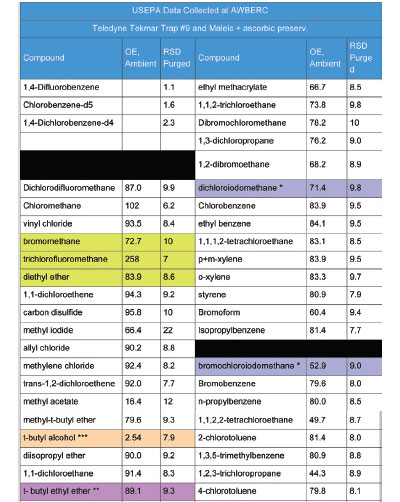

The U.S. EPA agreed to share with Teledyne Tekmar the data collected during the initial method development work. Overall efficiencies were calculated from these data. It is important to note that OE is the recovery relative to on-column injection. It includes the purge efficiency, trapping efficiency, desorb efficiency, and transmission through the entire sample path. There may be some inherent bias using this technique, and few agencies use this methodology. Overall efficiencies are expected to be lower, and may be technique as well as compound dependent. The U.S. EPA did report that the purge efficiency data collected averaged approximately 90% for the newly proposed target list. Data for OEs are presented in Table 4. Newly proposed target analytes from the Contaminant Candidate List were evaluated for OE as well. Again, these compounds did well using the Stratum PTC with RSDs under 10%. The OE data used for this analysis are presented in Table 5.

Table 4 - U.S. EPA OE data

Table 5 - Newly proposed CCL-3 OE

data

Conclusion

Overall efficiency can be influenced by several factors, including temperature, extraction volume, and sample size as well as the hardware used to extract the sample. For example, a glass vessel containing a frit for better gas distribution will generate more sample interaction than one without. The Stratum PTC has the capabilities to manipulate all of the above-mentioned factors to increase the efficiency recoveries. By employing an electronic mass flow controller, the entire key functions such as purge volume, water management, desorption, and cleanup can be controlled independently through the input of the user interface. This eliminates the need for manual pressure and flow setting traditionally associated with purge and trap.

The U.S. EPA has not yet finalized or released the proposed revision to Method 524.2; therefore a full method evaluation was not performed at this time. As the U.S. EPA continues to investigate compounds and controlling conditions, the Stratum PTC will aid in ease of use and provide the precision and accuracy required by today’s demanding environment.

Ms. Dattilio is VOC Product Specialist, Teledyne Tekmar, 4736 Socialville Foster Rd., Mason, OH 45040, U.S.A.; tel.: 513-229-7000; fax: 513-229-7050; e-mail: [email protected].