In a variety of industrial and environmental applications, the measurement of total organic carbon in water is an important analytical parameter in evaluating water quality. The Fusion analyzer and TOC TekLink™ software (Teledyne Tekmar, Mason, OH) combine to provide a wide range of user-friendly features and reliable data analysis. The software allows unattended autocalibration scheduling, automatic dilution capabilities using stock standards or samples, universal calibration, and blank methods for all detector ranges. Automated self-diagnostic tools, 21 CFR functionality (Electronic Records and Electronic Signatures [ERES]), exportable reports in various formats, and simple sample scheduling with minimal method development are also included. Default analytical parameters are set for total carbon (TC); total organic carbon (TOC); inorganic carbon (IC); and total organic carbon by analysis differential, i.e., total organic carbon analysis minus inorganic carbon analysis (TC–IC). The range of detection is from parts per trillion (ppt) to percent-level TOC with carryover of less than 1%.

Figure 1 - Fusion TOC analyzer.

The Fusion analyzer (Figure 1) is divided into four main compartments:

- Integrated autosampler. An integrated autosampler with improved automated syringe delivery system provides high precision and accuracy. The analyzer handles all liquid movement through a redesigned seven-port valve that is capable of accurately delivering volumes in 20-μL increments.

- Visible wet chemistry section. A visible wet chemistry section permits effortless examination of sample processing and maintenance. Grouping like components allows for easier maintenance as well as separation of the electronics and valves, preventing electrical components from possible liquid exposure in the unlikely event of valve failure. A dedicated IC chamber prepares samples for TOC analysis by adding phosphoric acid to the untreated sample and gas stripping inorganic carbon. An enhanced UV reactor increases sample oxidation for more pronounced UV radiation interaction between samples and oxidants. A highly efficient corrosive scrubber and mist trap eliminate corrosive gas and possible water interference from the sample gas stream before it enters the nondispersive infrared (NDIR) detector.

- Mass flow controller. Carrier gas used in the analysis is instantly controlled independent of temperature and source pressure fluctuations through a mass flow controller (MFC). Valves direct the gas flow controlled by the MFC. The combination of valves and MFC permits mode-to-mode changes to the flow rate. TOC TekLink software enables the user to optimize the sparge flow of the sample. Combined, these features result in lower gas use, since flow rates can be set instantaneously.1,2

- Static Pressure Concentration technology. The Fusion employs a CO2 detector designed to tolerate significant concentrations of SO2/SO3, moisture, and halogens. The detector uses patent-pending Static Pressure Concentration (SPC) combined with NDIR technology to achieve high performance at lower concentrations.3,4

Experimental

Figure 2 - Example of an autocalibration curve that was made from deionized water and 1-, 5-, and 10-mg C/L working stock solutions diluted from a 20-mg C/L potassium hydrogen phthalate stock solution.

The following experiments demonstrate the ability of the Fusion to recover after analyzing samples containing high carbon concentrations. The first uses the automatic dilution feature of TOC TekLink software. The method parameters, preset by the user, dilute each 100 milligrams per liter of (mg C/L) sample to a predetermined concentration within the active calibration range (Figure 2 and Table 1). The major aspect of the carryover calculation is the effect of the 100-mg C/L sample on the first replicate of the subsequent solutions, which are between 10- and 100-fold differences in concentration. Carryover for the 10-mg C/L and 1-mg C/L samples is less than 2%.

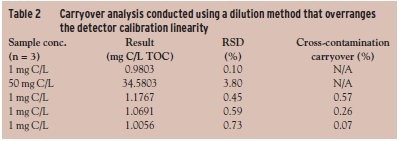

In the final experiment, the major aspect of the carryover calculation is the effect of the 50-mg C/L sample on the low-level samples. Although the 50-mg C/L sample is beyond the linearity of the calibration curve by fivefold, the Fusion again demonstrates its ability to rinse the sample pathway in between analyses. Carryover is less than 1% immediately following the out-of-linear-range sample, and the two samples subsequently show less than 0.1% carryover (Table 2).5,6

References

- Phoenix 8000 User; Teledyne Tekmar: Mason, OH, 2007.

- Fusion TOC User Manual; Teledyne Tekmar: Mason, OH, 2007.

- Heggs, E.T.; Price, E.K.; Proffitt, S.R. CO2 Measurements for TOC Analysis Using Static Pressure Reading of an NDIR. U.S. patent application, filed 2/21/07.

- Structure of the CARBOCAP® sensor; Vaisala: Helsinki, Finland, MRU p 1, Jan 2007.

- Yang, S.S.; Miller, M.; Martin, J.; Harris, J. Evaluation and application of a new total organic carbon analyzer. Application note. Teledyne Tekmar: Mason, OH, 2003.

- Wallace, B. Application of an Innovative Infrared Detection Technology to Total Organic Carbon Analysis of Pharmaceutical and Environmental Water Samples. Presentation given at Pittsburgh Conference, Chicago, IL, 2007.

Mr. Lawson is Applications Laboratory Manager, TeledyneTekmar, 4736 Socialville Foster Rd., Mason, OH 45040, U.S.A.; tel.: 800-874-2004; fax: 513-229-7050; e-mail: [email protected].