Texture testing is a well-established technique for evaluating the mechanical and physical properties of raw ingredients, food structure, and designs, and for pre- and post-quality control checks. Texture testing has applications across a wide range of food types, including baked goods, cereals, confectionaries, snacks, dairy, fruit, vegetables, gelatins, meat, poultry, fish, pasta, and even pet food. Since texture is a property related to the sense of touch, it can be measured easily by mechanical methods in units such as force. In texture testing, standard tests such as compression, tension, and flexure are used to measure hardness, crispiness, crunchiness, softness, springiness, tackiness, and other properties of food. Comparing the results from mechanical texture analysis with trained human sensory panels has shown that the measurements have a high correlation with the various sensory attributes associated with textural quality.

For natural products such as fruit, vegetables, meat, and fish, textural properties can be traced back to the way the product is grown, or reared, while for processed food, the textural properties can be used to optimize the process. Texture analysis can highlight quality improvement opportunities throughout the supply chain and the production process. At the research and development stage, new or alternative ingredients can be compared with existing ingredients. In production, texture analysis is used for the measurement and control of process variations such as temperature, humidity, and cooking time.

Figure 1 - Chatillon MT150 Series manual food firmness tester.

Different types of testing instrumentation available from AMETEK Measurement & Calibration Technologies Division (Largo, FL) range from manual and motorized food firmness testers to a fully software-controlled texture analyzer. Instrumental testing allows standards to be introduced and implemented and can provide full documentation of the test procedures. The Chatillon MT150 Series (Figure 1) is a manual mechanical tester suitable for determining the firmness of fruit and vegetables. It uses a portable mechanical or digital force gauge to make either tensile or compressive measurements. The tester can be driven with a lever or hand wheel, while a digital indicator or ruler may be used to measure the puncture depth.

For firmness testing or associated puncture, compressive-extrusion, cutting-shear, tensile, and compressive testing, the manually controlled, motorized Chatillon LTCM-100 Series tester can be used. It features a hand switch or optional foot switch to control tester speed and direction. A digital force gauge is used to determine the peak forces encountered in order to test the firmness characteristics of the sample. Force accuracy is achieved up to 0.1% of full scale. The tester is well suited for the QA/QC laboratory or production or research environment.

Figure 2 - TAPlus high-performance food texture analyzer.

The TAPlus (Lloyd Instruments) (Figure 2) is a high-performance food texture analyzer for fully automated texture analysis. Mechanical texture analysis, with a calibrated texture tester run by software using fundamental algorithms, removes all elements of subjectivity from the testing. Easy to operate, the 220 lbf (102 Kgf, 1000N) capacity food texture analyzer is designed for both routine and sophisticated texture analysis using NEXYGENPlus materials test and control software (Lloyd Instruments). Measurements are accurate to ±0.5% of the reading and speeds are accurate to <0.2%. The standard system includes the base instrument, drip tray, food testing base, and half-inch probe for routine applications. The closed-loop drive system enables precise instrument control during a test. This permits accurate sample height measurement for testing samples to a percentage of their original size, with the ability to adjust test speed relative to sample dimensions. The analyzer features a sizable working area to accommodate large samples, and can be fitted with a wide range of specially engineered food texture fixtures and probes as well as multipurpose grips for general applications such as packaging testing. Control is via the easily configured NEXYGENPlus software, which features a vast library of food industry-standard tests.

Typical tests

Some of the parameters that can be measured using a texture analyzer include adhesiveness, chewiness, cohesiveness, consistency, crispiness, crunchiness, elasticity, extensibility, firmness, fracturability, gel strength, gumminess, hardness, rupture strength springiness, stiffness, stringiness, texture profile analysis toughness, work to cut, work to penetrate, and work to shear.

Figure 3 - Volodkevitch Bite Set fixture.

Key to the versatility of the texture analysis technique is the availability of over 70 probes, fixtures, and jigs that can allow the use of a single instrument to make a diverse range of measurements in a variety of food applications. The Volodkevitch Bite Set fixture is a good illustration of how the instrument translates a human action into a measurable quantity. It is designed to imitate incisor teeth shearing through meat, vegetables, fruit, and crispy or crunchy food products. The set comprises upper and lower “teeth” (Figure 3) that are brought together until they are almost touching. The sample is positioned on the lower “tooth,” and the result is measured as the peak force required to bite through the sample. The results correlate with the tenderness, toughness, and firmness of the sample. Grips and fixtures are available in a variety of sizes, gripping surfaces, styles, and capacities to meet different applications. The choice of specimen size depends on the homogeneity of the sample. A food with large voids will require a larger sample size than a food without voids to obtain similar repeatability. The choice of fixtures depends on the sample; if the sample has a flat surface, then generally compression platens that are larger than the sample are used. For surfaces that are uneven, such as fruit and vegetables, small-diameter probes are used.

Food testing fixtures

Figure 4 - Burger consistency test jig.

Texture analysis grips and fixtures are developed regularly to further enhance the range of applications. Two test jigs for the TAPlus texture analyzer include one for the analysis of uncooked hamburger patties, which provides an objective measure of burger consistency. The second jig measures pasta stickiness. The huge demand for burgers, together with competitive pricing, means that their composition can vary significantly, from 100% prime ground beef to poor-quality meat containing a high percentage of fat, bulking agents, salt, and other additives. For testing, the burger is placed on a support plate containing a 27-mm-diam hole mounted on the TAPlus base table. A cylindrical probe, which opens out in an inverted cone shape with a flat end of 25 mm diam, is used to apply force to the burger (Figure 4). The jig can also be used for testing re-formed cooked meat.

Figure - 5 Lasagne stickiness test jig.

The stickiness of cooked sheets of pasta such as lasagne is related to the starch content of the pasta sheet, which in turn is related to the cooking temperature and time. These parameters can be optimized by measuring pasta stickiness. The cooked pasta sheet is mounted between the TAPlus base table and a rectangular plate containing a rectangular hole. A matching rectangular probe is used to apply a uniform compression force to the pasta sheet through the hole (Figure 5). The force required to withdraw the probe is then measured. The probe may be held in contact with the pasta sheet for a predefined time before withdrawal, if required.

Figure 6 - Five-blade Kramer Type Shear Cell.

Although the jigs are designed for specific applications, new test fixtures for more general applications are also of interest. A five-blade version of the Kramer Type Shear Cell (Figure 6) is an alternative to the conventional 10-blade configuration and is designed for measuring the bulk shear and extrusion forces of meats, fruit, and cereals, especially where the samples have irregular shapes and sizes and the forces expected are too high for the traditional 10-blade version. The Kramer Type Shear Cell comprises five parallel steel blades, which are driven down through guide slots into a rectangular container with corresponding slots in the base. The sample is sheared, compressed, and extruded through the bottom openings. Since the blades are set further apart than on the 10-blade version, there is a reduction in the force of bulk shearing or compression on samples with many particles or foods with nonuniform texture. The accessory operates from ambient temperature up to 100 °C, and is fitted with a spill container, which can also be used with the 10-blade version.

Software control

While the mechanical jigs and fixtures allow an increased range of testing options, software control of the texture analyzer permits the operator to control and monitor all aspects of the system and configure the tests themselves. NEXYGENPlus texture analysis software for the TAPlus texture analyzer features a comprehensive library of industry-standard test methods covering food, cosmetics, and packaging tests to AACC, ASTM, DIN, EN, ISO, and other standards. The software also offers user-defined test creation, data collection, reporting and exporting of test data, video and still picture capture, test data security and audit trails, and test automation and customization. The standard user-configurable test can be employed to create specialized multistage tests and is particularly beneficial for texture profile analysis, which replicates the effect of two bites on a sample. The software captures force, distance, and time during the test, enabling parameters such as adhesion force, adhesiveness, chewiness, cohesiveness, firmness, fracturability, gumminess, hardness modulus, resilience, springiness, and stringiness to be calculated.

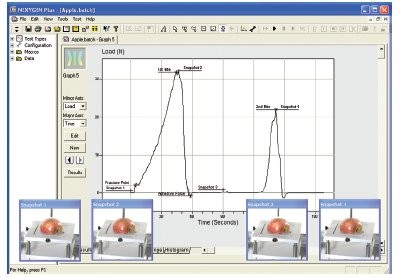

Figure 7 Texture profile analysis of an apple with still pictures.

In addition to the powerful measurement facilities, the software provides capabilities that can greatly enhance the presentation and understanding of test results. For example, video images of the entire test can be recorded and synchronized with the stress/strain data and replayed for detailed post-test analysis. Alternatively, still images can be taken at specific points during the test. These still images are recorded on the graph for ease of analysis (Figure 7). In addition, external plug-and-play devices such as temperature and humidity probes may be connected to the system to enable these parameters to be monitored during a test and reported in the software against force, distance, and time. Test start and stop conditions may also be controlled by these external devices. The security and audit trail module enables supervisors to manage user access and data traceability. The module can also be configured to assist manufacturers with FDA 21 CFR Part 11 compliance requirements. Electronic signatures and the ability to restrict user access rights increase security and avoid costly errors. Integrated audit trails covering operator usage and test results ensure that all changes to test procedures are recorded in a simple retrievable format.

Custom applications

In addition to the many standard tests that utilize the fixtures described above and others, many researchers opt to develop their own tests. Software control provides the versatility to create and conduct the appropriate test; all that is required is a special jig or fixture to hold the particular sample for the required test. The manufacturer provides a service that designs and fabricates specialized jigs. Many food products are packaged in flexible wrap that is required to be tested for its tensile strength, puncture resistance, heat bond peel strength, tearing strength, and coefficient of friction. The TAPlus can be easily configured as a dual texture analysis and packaging testing system by changing fixtures, offering even greater versatility.

Mr. Brown is Brand Manager, Chatillon, Lloyd Instruments, and Davenport Brands,AMETEK Measurement & Calibration Technologies Division, 8600 Somerset Dr., Largo, FL 33773, U.S.A.; tel.: 800-527-9999; fax: 727-539-6882; e-mail: [email protected].