High-performance liquid chromatography (HPLC) has proven to be the predominant

technology used in laboratories

worldwide during the past 30-plus

years. One of the primary drivers for the

growth of this technique has been the

evolution of packing materials used to

effect the separation. The underlying

principles of this evolution are governed

by the van Deemter equation, with

which any student of chromatography is

intimately familiar.1 The van Deemter

equation is an empirical formula that

describes the relationship between linear

velocity (flow rate) and plate height

(HETP or column efficiency). Since

particle size is one of the variables, a van

Deemter curve can be used to investigate

chromatographic performance.

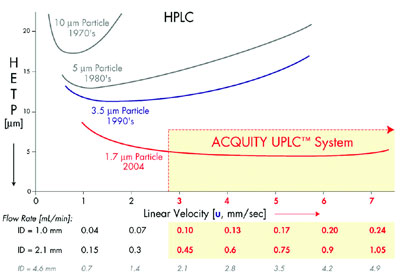

As illustrated in Figure 1, as the particle

size decreases to less than 2.5 μm,

not only is there a significant gain in

efficiency, but the efficiency does not

diminish at increased flow rates or linear

velocities. By using smaller particles,

speed and peak capacity (number

of peaks resolved per unit time) can be

extended to new limits, termed Ultra Performance Liquid Chromatography

or UPLC™ (Waters Corp., Milford,

MA). Using UPLC, it is possible to

take full advantage of chromatographic

principles to run separations

using shorter columns and/or higher

flow rates for increased speed with

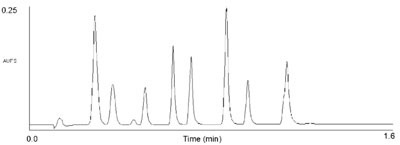

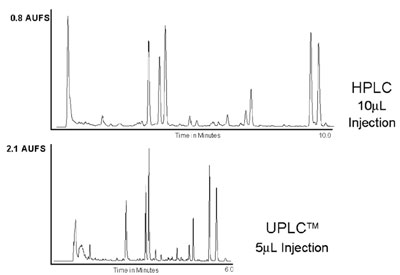

superior resolution and sensitivity. Figures

2 and 3 further illustrate UPLC in

action. With UPLC, compromises are

no longer necessary; in Figure 2 a separation

of eight diuretics is accomplished

in under 1.6 min. The same

separation on a 2.1 × 100 mm, 5-μm

C18 HPLC column yields almost identical

resolution, but takes 10 min. For

some analyses, however, speed is of

secondary importance; peak capacity

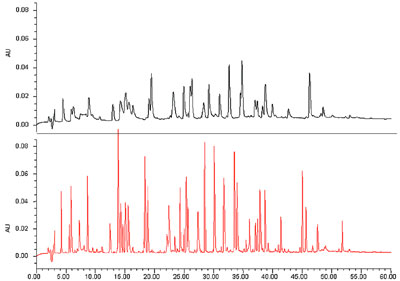

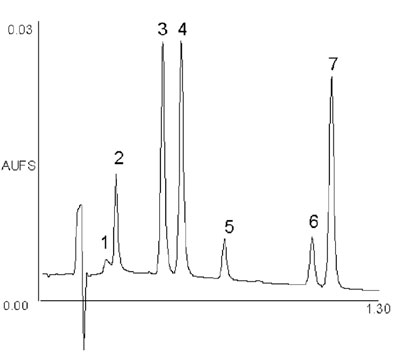

and resolution take center stage. Figure

3 shows a peptide map in which

the desired goal is to maximize the

number of peaks. In this application,

the increased peak capacity (number

of peaks resolved per unit time) of

UPLC dramatically improves the quality

of the data, resulting in

a more definitive map.

Figure 1 - van Deemter plot illustrating the evolution of particle sizes over the last three decades.

Figure 2 - UPLC separation of eight diuretics. Column:

2.1 × 30 mm, 1.7-μm ACQUITY UPLC BEH C18 at 35

°C. A 9–45%B linear gradient over 0.8 min, at a flow rate of

0.86 mL/min, was used. Mobile phase A was 0.1% formic

acid; B was acetonitrile. UV detection was at 273 nm. Peaks

are in order: acetazolamide, hydrochlorothiazide, impurity,

hydroflumethiazide, clopamide, trichlormethiazide, indapamide,

bendroflumethiazide, and spironolactone; 0.1 mg/mL

each in water.

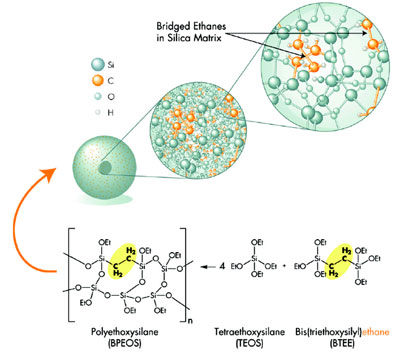

Chemistry of small particles

Figure 3 - Synthesis and chemistry of ACQUITY BEH 1.7-μm particles for UPLC.

The design and development

of sub-2-μm particles

is a significant challenge,

and researchers have been

active in this area for some

time to capitalize on their

advantages.2,3 Although

high-efficiency, nonporous

1.5-μm particles are commercially

available, they suffer

from poor loading capacity

and retention due to low

surface area. Silica-based particles have

good mechanical strength, but can suffer

from a number of disadvantages, which

include a limited pH range and tailing of

basic analytes. Polymeric columns can

overcome pH limitations, but they have

their own issues, including low efficiencies

and limited capacities.

XTerra® (Waters Corp.), a first-generation

hybrid chemistry that took

advantage of the best of both the silica

and polymeric column worlds, was

introduced in 2000. XTerra columns

are mechanically strong, with high

efficiency, and operate over an

extended pH range. They are produced

using a classical sol-gel synthesis

that incorporates carbon in the form of

methyl groups. In order to provide the

kind of enhanced mechanical stability

UPLC required, however, a second-generation

bridged ethane hybrid

(BEH) technology was developed: ACQUITY BEH (Waters Corp.).

ACQUITY BEH 1.7-μm particles

derive their enhanced mechanical stability

by bridging the methyl groups in

the silica matrix, as shown in Figure 4.

Figure 4 - HPLC vs UPLC peak capacity. In this gradient peptide map separation,

the HPLC separation (top) (on a 5-μm C18 column) yields 70 peaks, or a peak capacity

of 143, while the UPLC separation (bottom) run under identical conditions yields

168 peaks, or a peak capacity of 360, a 2.5× increase.

Packing a 1.7-μm particle in reproducible

and rugged columns was also a

challenge that needed to be overcome.

Requirements include a

smoother interior surface of the column

hardware and redesigning the

end frits to retain the small particles

and resist clogging. Packed-bed uniformity

is also critical, especially if

shorter columns are to maintain resolution

while accomplishing the goal of

faster separations. All ACQUITY

BEH columns also include eCord™

microchip technology, which captures

the manufacturing information for

each column, including the quality

control tests and Certificates of Analysis.

When used in the ACQUITY UPLC™ System (Waters Corp.), the

eCord database can also be updated

with real-time method information

such as the number of injections, or

with pressure information, to maintain

a complete column history.

Capitalizing on smaller particles

Instrument technology also had to keep

pace to truly take advantage of the

increased speed, superior

resolution, and sensitivity

afforded by smaller particles.

Standard HPLC

technology simply does

not have the horsepower

to take full advantage of

sub-2-μm particles. A new

system design with

advanced technology in

the pump, autosampler, detector, data system, and

service diagnostics was

required. The ACQUITY UPLC System has been

holistically designed for

low system and dwell volume

to take full advantage

of low-dispersion and

small-particle technology.

Achieving small-particle,

high-peak-capacity

separations requires a greater pressure

range than that achievable by today’s

HPLC instrumentation. The calculated

pressure drop at the optimum

flow rate for maximum efficiency

across a 15-cm-long column packed

with 1.7-μm particles is approx. 15,000

psi. Therefore, a pump capable of

delivering solvent smoothly and reproducibly

at these pressures that can

compensate for solvent compressibility

and operate in both the gradient and

isocratic separation modes is required.

Sample introduction is also critical.

Conventional injection valves, either

automated or manual, are not

designed and hardened to work at

extreme pressure. To protect the column

from experiencing extreme pressure

fluctuations, the injection process

must be relatively pulse free. The

swept volume of the device also needs

to be minimal to reduce potential

band spreading. A fast injection cycle

time is needed to fully capitalize on

the speed afforded by UPLC, which in

turn requires a high sample capacity.

Low-volume injections with minimal

carryover are also required to realize

the increased sensitivity benefits.

With 1.7-μm particles, half-height

peak widths of less than 1 sec are

obtained, posing significant challenges

for the detector. In order to accurately and reproducibly integrate an analyte

peak, the detector sampling rate must

be high enough to capture enough

data points across the peak. In addition,

the detector cell must have minimal

dispersion (volume) to preserve

separation efficiency. Conceptually,

the sensitivity increase for UPLC

detection should be 2–3 times higher

than HPLC separations, depending on

the detection technique. MS detection

is significantly enhanced by

UPLC; increased peak concentrations

with reduced chromatographic dispersion

at lower flow rates (no flow splitting)

promote increased source ionization

efficiencies.

Shown in Figure 5, the ACQUITY

UPLC System consists of a binary solvent

manager, sample manager (including

the column heater), detector, and

optional sample organizer. The binary

solvent manager uses two individual

serial flow pumps to deliver a parallel

binary gradient. There are built-in solvent

select valves that let the user

choose from up to four solvents. There

is a 15,000-psi pressure limit (approx.

1000 bar) to take advantage of the sub-2-μm particle in the linear velocity per

the van Deemter curve. The sample

manager also incorporates several technology

advancements. Low dispersion

is maintained through the injection

process using pressure assist sample

introduction, and a series of pressure

transducers facilitate self monitoring

and diagnostics. Needle-in-needle sampling

improves ruggedness, and a needle

calibration sensor increases accuracy.

Injection cycle time is 25 sec

without a wash and 60 sec with a dual

wash used to further decrease carryover.

A variety of multiple-well plate formats

(deep-well, mid-height, or vials) can

also be accommodated in a thermostatically

controlled environment. Using

the optional sample organizer, the sample

manager can inject from up to 22

multiple-well plates. The sample manager

also controls the column heater.

Column temperatures up to 65 °C can

be attained. A “pivot out” design provides

versatility to allow the column outlet to be placed in closer

proximity to the source

inlet of an MS detector to

minimize sample dispersion.

Figure 5 - ACQUITY UPLC System.

The ACQUITY UPLC Tunable UV (TUV) Detector

(Waters Corp.) includes

new electronics and

firmware to support Ethernet

communications at the

high data rates necessary for

UPLC detection. Conventional

absorbance-based

optical detectors are concentration

sensitive; for

UPLC use, the flow cell volume

would have to be

reduced in standard UV-VIS

detectors to maintain

concentration and signal.

Smaller-volume conventional

flow cells would also

reduce the pathlength upon

which the signal strength depends

(recall Beer’s Law). Worse, a reduction

in cross-section means the light path is

reduced and transmission drops, increasing

noise. Therefore, if a conventional

HPLC flow cell is used, UPLC sensitivity

would be compromised. The

ACQUITY UPLC TUV detector cell

consists of a light-guided flow cell

equivalent to an optical fiber. Light is

efficiently transferred down the flow cell

in an internal reflectance mode that still

maintains a 10-mm flow cell pathlength

with a volume of only 500 nL. Tubing

and connections in the system are efficiently

routed to maintain low dispersion

and to take advantage of leak

detectors that interact with the software

to alert the user to potential problems.

Applications

Figure 6 - Comparison of HPLC and UPLC for the separation

of a ginger root extract. HPLC conditions—Column:

2.1 × 100 mm, 5.0-μm prototype BEH C18 at 28 °C. A

25–96%B linear gradient over 10 min, at a flow rate of 1.0

mL/min, was used. Mobile phase A was water; B was acetonitrile.

UV detection was at 230 nm, 10-μL injection. UPLC

conditions—column: 2.1 × 100 mm, 1.7-μm ACQUITY

BEH C18 at 28 °C. A 50–100%B linear gradient from 1.4

to 3.7 min followed by a hold until 6.0 min, at a flow rate of

0.3 mL/min, was used. Mobile phase A was water; B was

acetonitrile. UV detection was at 230 nm, 5-μL injection.

Chromatographers are used to making

compromises, and one of the most common scenarios involves sacrificing

resolution for speed. In addition,

for complex samples such as

natural product extracts, added resolution

can provide more information

in the form of additional peaks.

Figure 6 shows an HPLC versus

UPLC separation comparison of a

ginger root extract sample where

both speed and resolution are

improved, as well as an increase in

sensitivity. DryLab software (Rheodyne,

Rohnert Park, CA) was used to

model and redevelop the separation

and transfer it to the ACQUITY

UPLC System and BEH chemistry.

Figure 7 - UPLC separation of seven coumarins illustrating

fast method development. Column: 2.1 × 30 mm, 1.7-μm

ACQUITY UPLC BEH C18 at 35 °C. A 20–40%B linear

gradient over 1.0 min, at a flow rate of 0.86 mL/min, was

used. Mobile phase A was 0.1% formic acid; B was acetonitrile.

UV detection was at 254 nm and 40 pts/sec. Peaks are in

order: 7-hydroxycoumarin-glucuronide, 7-hydroxycoumarin,

4-hydroxycoumarin, coumarin, 7-methoxycoumarin,

7-ethoxycoumarin, and 4-ethoxycoumarin.

Faster separations can lead to higher

throughput and time savings when

running multiple samples. However, a

significant amount of time can also be

consumed in developing the method

in the first place. Faster, higher-resolution

UPLC separations can cut

method development time from days

to hours or even minutes. Figure 7 is

an example of a UPLC separation of

several closely related coumarins and

a metabolite that was developed in

under 1 hr, including UPLC scouting

runs for gradient optimization and

individual runs for elution order identification.

These runs were performed

in a fraction of the time that would be necessary with conventional

HPLC, resulting in significant

time savings in the

method development laboratory.

Conclusion

At a time when many scientists

have reached separation

barriers pushing the limits of

conventional HPLC, UPLC

presents the possibility to

extend and expand the utility

of this widely used separation

science. New ACQUITY

UPLC technology in chemistry

and instrumentation provides

more information per

unit of work as UPLC begins

to fulfill the promise of

increased speed, resolution,

and sensitivity predicted for

liquid chromatography.

References

- van Deemter JJ, Zuiderweg FJ, Klinkenberg A. Chem Eng Sci 1956; 5:271.

- Jerkovitch AD, Mellors JS, Jorgenson JW. LC·GC North America 2003; 21:7.

- Wu N, Lippert JA, Lee MA. J Chromotogr 2001; 911:1.

Dr. Swartz is Principal Consulting Scientist, and

Mr. Murphy is Manager, Corporate Communications,

Waters Corp., 34 Maple St., Milford, MA

01757, U.S.A.; tel.: 508-482-2742; fax: 508-482-3085; e-mail: [email protected].

The authors would like to acknowledge the contributions

of the ACQUITY program team at

Waters, particularly Eric Grumbach, Pat

McDonald, Michael Jones, and Marianna Kele,

for their contributions to this manuscript.