When SPECTRO Analytical Instruments (Kleve, Germany) sought to redesign its inductively coupled plasma (ICP) spectrometer instrument line, the company’s engineers worked to address some very specific features and functions of interest to users of the technology. The result is a range of instruments from high-end to baseline models; they may include such features as air-cooled load coil (no attached circulator/chiller), sealed UV Plus optics and dedicated radial and axial analysis in the same instrument.

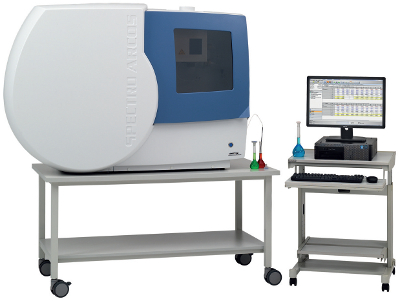

Figure 1 – SPECTRO ARCOS ICP-OES.

Figure 1 – SPECTRO ARCOS ICP-OES.The top-of-the-line SPECTRO ARCOS ICP-OES (Figure 1) is most at home in high-volume labs with challenging applications. The optical system is the heart of any OES, and the one designed for the ARCOS provides unrivalled performance for the most challenging samples. The analyzer’s innovative Optimized Rowland Circle Alignment (ORCA) optical technology utilizes few mirrors, providing a direct, high-luminance light path that minimizes light loss. This enables SPECTRO ARCOS to deliver constant resolution over a wide spectral range. With its optimized holographic master gratings housed in a single cast-aluminum hollow-section optical chamber featuring 32-line array detectors, SPECTRO ARCOS has a wavelength range from 130 nm to 770 nm and enables simultaneous capture of a sample’s complete relevant spectrum in under 4 seconds. It employs three integrated, optimized optical systems to provide full-wavelength coverage. The wavelength range and uniform optical resolution allows accurate analysis of even the most complex matrices.

In earlier instrument designs, the need for a standalone water recirculator to cool the instrument’s plasma load coil added to the system’s complexity. This was especially risky in high-volume labs, where a chiller malfunction could bring work to a halt. These conventional cooling units run water through a loop—they don’t need a continuous supply, but must be topped off now and then.

To improve system uptime, SPECTRO engineered a system that allows heat to be extracted from the interface and the torch area using an air-cooled heat exchanger—no cooling unit is required. Heat is removed through the existing lab exhaust system, so no extra ventilation is needed. Mindful of the high heat generated by the instrument’s plasma torch, SPECTRO undertook extensive studies to verify that during operation, the system delivered no heat buildup, which might otherwise cause drift. During these studies it was discovered that the air-cooled design actually created a more temperature-stable environment than a water-cooled system. Not only was the overall reliability improved, the analytical stability is also enhanced.

In addition to reducing operating costs by elimination of the cooling system, SPECTRO has also patented cost-saving innovations in the optical system. In conventional ICP-OES, it is necessary to eliminate atmospheric oxygen from the optical system. Removing it allows analysis of UV elements and enhances stability of near-UV elements. Removing the oxygen is most often accomplished by flushing the optic with argon or nitrogen— effectively replacing atmospheric oxygen with a continuous flow of inert gas. To eliminate this expense, SPECTRO has developed the UV-PLUS sealed optical system. Used exclusively in the SPECTRO ARCOS and SPECTROBLUE, this feature recirculates argon through the optical system without loss. The only maintenance is replacement of a cleaning cartridge once every two years. This eliminates the waste and expense (typically more than $3000 a year) required by conventional constant-purge designs, which also risk system contamination by purge gases.

An added benefit of gas recirculation is a more complete removal of oxygen than a traditional purge. The virtually complete removal gives access to halogens. Chlorine, bromine and iodine—elements not typically analyzed by ICP, but often tested in high-volume industrial laboratories—can be run on SPECTRO ARCOS because of its unusually wide 130–770 nm wavelength coverage.

The first commercial adaption of an ICP-OES utilized what is known as a radial view of the plasma. Plasma is actually a hot stream of ionized argon gas. It is toroidal shaped with the liquid sample nebulized through its center. The plasma provides enough power and stability to fully desolvate the sample, break down the molecular structure and excite the individual elements. These elements emit a characteristic photon when dropping back to ground state. This emission of light is the measurement of interest in ICP-OES. Early studies showed observing the plasma in a radial view provided the best signal-to-noise ratio. Years later, in a step change of the technology, axial views were proven to offer lower levels of detection and were widely adopted in the environmental laboratory. However, limitations of the axial view included reduced linear range and a host of interferences not seen in the radial view. A solution was devised with the introduction of the twin interface. It adopts a traditional axial view, with the addition of an optical periscope to pass a limited radial view to the optic. SPECTRO utilizes this style of switchable plasma viewing in the SPECTROBLUE. While versatile, there are limitations. The radial view of a dual view optic is compromised. Unlike a dedicated radial view plasma, light from the radial view in a dual viewing arrangement must pass through additional mirrors or lenses—limiting its performance.

With its recent development of MultiView technology, SPECTRO has been able to deliver an instrument that provides both a true radial view and a true axial view. A SPECTRO ARCOS analyzer equipped with the MultiView option allows physical rotation of the plasma torch, so that within 90 seconds the instrument can be changed from one fully functional view to the other. For a scientist presenting a range of different applications to the instrument, this provides great benefit. An example would be a company running both plating bath solutions and wastewater. Plating bath solutions are typically very high salts with a variety of concentrated metals. The preferred view is radial to minimize interferences and maximize sensitivity. With MultiView, the instrument can quickly be converted from a dedicated radial view for the plating bath to an axial view for the lowest limits of detection on wastewater.

Further examples wherein this capability is useful might include alkaline elements, which are typically studied in the radial view because they present some ionic buff ering issues, while transitional elements might benefit from axial view, because they are less affected by these issues.

All these capabilities are important to industrial clients, and any users that have high performance demands.

Figure 2 – SPECTROBLUE analyzer.

Figure 2 – SPECTROBLUE analyzer.With the introduction of the SPECTROBLUE analyzer (Figure 2) in 2011, the goal was to take a top-of-the-line product and make it appropriate for the commercial environmental laboratory. In this type of lab, the samples submitted typically belong to a fixed, regulatory-driven list. Lab personnel know what they need to run, and they know within what levels they need to operate.

Starting with the SPECTRO ARCOS platform, SPECTRO engineers initiated a judicious redesign for SPECTROBLUE. Specifications for level of detection were not changed, but a SPECTRO ARCOS spectrometer’s ability to analyze chlorine, bromine, iodine and other far-UV elements was not needed for the target market. Like the ARCOS, the external cooling system was eliminated and the UV-Plus system was included. These features ensure low cost of operation. SPECTROBLUE emerges as a midrange instrument that addresses the cost and performance requirements of environmental customers—an analyzer tailored to their specific needs.

Figure 3 – SPECTRO GENESIS ICP.

Figure 3 – SPECTRO GENESIS ICP.SPECTRO GENESIS (Figure 3) is an entry-level ICP designed for better affordability than others in its class, giving users of atomic absorption spectroscopy (AAS) instruments an upgrade path to more advanced ICP performance—without sacrificing the key benefits of simultaneous analysis and robust matrix tolerance.

SPECTRO GENESIS has been very successful in applications such as those in the petrochemicals sector. Performing oil additive analysis, waste oil analysis and similar sample analysis tasks, the instrument offers sensitivity that is perfectly acceptable for the level of detection required in these applications. Not unlike other instruments in its class, it comes with a set of factory-installed methods for common environmental and industrial methods: water, wastewater, soil, wear metals in oil, additives in oil and others. It is compliant with national and international norms, and is delivered ready for use.

Over all its product lines, SPECTRO focuses on using core competency in elemental analysis plus sophisticated engineering to address specific challenges that users in various sectors face in analyzing their samples. Further interesting developments—in ICP, XRF and metals analysis technologies—can be expected as these needs evolve.

Mark Grey is Vice President, SPECTRO Analytical Instruments, 91 McKee Dr., Mahwah, N.J. 07430, U.S.A.; www.spectro.com