The moisture absorbing polymer consumable described in this article is designed to remove moisture from wet samples inline during extraction as well as from the post-extraction solvent extract. Thermo Scientific ™ Dionex™ ASE™ Prep MAP moisture absorbing polymer (Thermo Fisher Scientific, Waltham, MA) is a copolymer (see Figure 1) of an anionic and cationic monomer. MAP’s unique formulation facilitates moisture removal in a wide range of ionic strength and inline accelerated solvent extraction (ASE) applications. The polymer can be easily mixed with Dionex ASE Prep DE (diatomaceous earth) in a 1:1 ratio for moisture removal extraction applications from wet samples and under high-temperature and high-pressure conditions.

Figure 1 – Dionex ASE Prep MAP moisture-absorbing polymer.

Figure 1 – Dionex ASE Prep MAP moisture-absorbing polymer.Accelerated solvent extraction technique

Organic compound analysis is becoming more and more important; also growing in importance is the need for isolation and analysis of trace levels of compounds from such matrices as sediment, soil, fruits, vegetables, and animal tissue. Accelerated solvent extraction is a technique that is used to extract the analytes of interest from a solid, semisolid, or adsorbed liquid sample. ASE performs extraction using an organic solvent at elevated temperature and pressure conditions. The elevated pressure increases the boiling temperature of the solvent and extraction can occur at relatively high temperatures, which leads to faster extractions. The extraction process is therefore significantly faster than traditional methods such as Soxhlet extraction. Both the Dionex ASE 150 and 350 systems (Figure 2) effectively carry out the solvent extraction procedure.

Figure 2 – Dionex ASE 350 system.

Figure 2 – Dionex ASE 350 system.Challenges with wet samples

It is well known that the presence of moisture in the sample can interfere with the efficiency of the extraction process. The analyte can partition between the aqueous phase from the moisture and the solvent phase from the extraction, resulting in poor recoveries. Moreover, co-extract water can cause issues with the analysis. For example, the presence of moisture is undesirable when performing GC analysis. Another issue is that, when the extract is evaporated, the aqueous phase can sputter and result in low recovery of analytes; in some cases the solvent moisture mixture can form azeotrope, which in turn can also result in analyte recovery problems.

Traditional drying protocols

In some samples that contain moisture or water, an additional step may be required either before or after the extraction step to remove the moisture. Before extraction, sample drying can be done using a procedure such as air drying or oven drying. However, neither drying protocol is suitable when analyzing volatile or semivolatile components, since these compounds would be removed from the sample prior to extraction or analysis.

Sodium sulfate as a drying agent

U.S. EPA Method 3545 recommends that the wet soil/sediment may be air dried or chemically dried with sodium sulfate. A common method for moisture removal is to use salts such as sodium sulfate, calcium chloride, magnesium sulfate, and calcium sulfate. These salts tend to associate to water molecules to form hydrated salts. Sodium sulfate, for example, tends to clump together when water is present. Sodium sulfate can dissolve in hot solvent to a small degree and in some cases can precipitate downstream, clogging the outlet frit, tubes, and valves. Moreover, sodium sulfate becomes an aggregate hard lump upon water absorption and is not easy to process during sample preparation for in-cell moisture removal and extraction. Hence, sodium sulfate is not suitable for in-cell moisture removal and extraction using the Dionex ASE system. In addition, with sodium sulfate user intervention is required, i.e., the operator must adjust the amount for a given moisture level.

MAP polymer

The water-absorbing ability of the MAP is independent of the ionic strength of the sample matrix, making it more suitable for sample preparation applications. The polymer absorbs water, and the water is held in the polymer matrix by hydrogen bonding. The MAP has a high capacity for water removal and does not suffer from the limitations outlined above for sodium sulfate salt.

In-cell mode

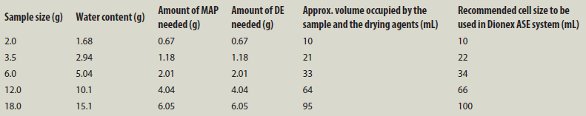

The in-cell moisture removal mode is designed for inline moisture removal inside the ASE cell in the Dionex ASE instrument. The MAP is combined with the DE, preferably in a 1:1 ratio, to aid moisture removal (see Tables 1 and 2). Addition of DE is recommended and results in improved flow and moisture removal. Table 1 shows the amount of MAP and DE required for in-cell moisture removal in the ASE technique under a variety of common temperatures. It is clear that as the temperature increases the water removal decreases. Typically, this mode is recommended for all samples in which the extraction method is run at 125 ºC and below. The benefit of this mode is that there is no need to dry the sample or remove the moisture in a postextraction step.

Table 1 – Amounts of MAP polymer and DE required for in-cell moisture removal at various temperatures

An example of a high-moisture-content sample is shown in Table 2. The moisture content of the sample is roughly 84%. The amount of MAP needed can be calculated based on the water content and the information given in Table 1. Table 2 also provides some guidelines on the cell size needed for a given sample size. Therefore, for a given sample size, the user will know the amounts of MAP and DE needed to start the sample preparation protocol for the wet sample and the corresponding cell to use. An excess of polymer in conjunction with DE can be used for samples containing unknown moisture content.

In-vial mode

The in-vial moisture removal mode is designed for off-line moisture removal such as with the collected solvent extract from the Dionex ASE 150/350 system. The MAP is added in this mode to the extract for moisture removal. The amount of moisture-absorbing polymer needed is 0.20 ± 0.05 g for absorbing 1 g of water at room temperature. In contrast, more than 4 g of sodium sulfate is needed for absorbing 1 g of water at room temperature. The extract can also be dried by passing it through a bed of MAP placed on a filter paper. This mode is applicable to all accelerated solvent extraction methods independent of temperature.

Combination mode

In the combination mode, in-cell moisture removal is followed by in-vial moisture removal. If some breakthrough of moisture is observed in the extract during extraction, then addition of a small amount of polymer in the collection bottle can result in complete moisture removal.

Sample types

Typical samples such as wet soil and sediments (see U.S. EPA Methods 3545, 1668, and 1699), animal tissue-based samples such as meat and fish, and food samples such as fruits and vegetables can be dried using the MAP and DE in the in-cell mode.

Table 2 – In-cell moisture removal by the MAP and DE at 100 ⁰C for various cell and sample sizes in ASE

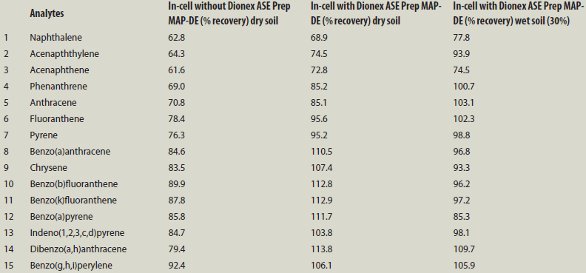

Table 3 – PAH recovery using GC-FID

Application of moisture-absorbing polymer

Polycyclic aromatic hydrocarbon (PAH) extraction was performed from spiked wet soil following in-cell moisture removal using MAP and DE (1:1 ratio). (Detailed sample preparation protocols are described in the MAP product manual.) The soil sample was then extracted employing the Dionex ASE 350 system using acetone/dichloromethane (1:1) at an extraction temperature of 100 ºC. The extracts were analyzed using GC-FID (gas chromatography-flame ionization detection); the results are shown in Table 3. PAH recovery results from wet soil for in-cell moisture removal are shown in the rightmost columns compared to two dry soils. Note that when the dry sample was not dispersed homogeneously, the recoveries shown in the first data column were not good. The recoveries increased, as shown in the second data column, when the dry sample was dispersed with dispersant such as MAP and DE. Good recoveries were obtained when the wet soil was dried using MAP and DE, as is evident from the data in the far-right column. Therefore, the utility of the polymer as a drying agent is evident from Table 3. It should be noted that further optimization of the extraction method is needed to improve the recovery of the two naphthalene compounds (Analytes #1 and 3).

Conclusion

The MAP is designed as a drying agent for in-cell (in-line) or in-vial (off-line) moisture removal applications. The polymer overcomes the limitations of salts such as sodium sulfate used for in-cell moisture removal and extraction, and thus can replace the use of sodium sulfate as a drying agent. Drying the wet sample using the MAP and DE is also faster than air drying, oven drying, and freeze drying.

Rahmat Ullah is Senior Chemist; Kannan Srinivasan is Director, Research Science; Chris Pohl is Vice President, Chromatography Chemistry; and Pranathi Perati is Product Manager, Thermo Fisher Scientific, 445 Lakeside Dr., Sunnyvale, CA 94085, U.S.A.; tel.: 408-481-4645; e-mail: rahmat.ullah@ thermofisher.com ; www.thermofisher.com