According to the Occupational Safety and Health Administration (OSHA), on average, it takes between 18 and 36 months to develop and implement a new regulation, trailing the pace of science. As a result, life scientists developing new techniques are simultaneously developing the standards for laboratory safety and maintaining sample integrity.

There are more than 500,000 workers employed in laboratories in the U.S., many of whom are exposed to numerous potential chemical, biological, physical, and radioactive hazards, as well as musculoskeletal stress.

When implemented, new pipetting products can make the workplace significantly safer for molecular and cell biologists and increase data reliability, which in turn have long-term positive effects for workers and genomic information. The assays performed by these scientists are complicated and require a fair amount of routine pipetting to prepare samples.

Efficacy of new liquid handling systems

Figure 1 – Microlab 300 Series Pipettor, the first guided pipetting system.

Figure 1 – Microlab 300 Series Pipettor, the first guided pipetting system.In the last decade, companies have added more safeguards and automation to their instrument offerings. Semiautomated devices have recently been developed for smaller labs on a budget. The Microlab® 300 (Hamilton, Reno, NV) is a guided pipetting system that replaces 3–4 manual or electronic pipets with one device and costs less than multiple manual pipettors. The system, shown in Figure 1, can dispense between 0.5 and 1000 μL without exchanging pipets. This eliminates the steps for which repetitive force creates repetitive stress.

The lightweight, handheld device also enables laboratories to achieve quality assurance through reproducible and traceable programmable methods, and reduce sample preparation time by eliminating inefficient steps. The Microlab 300 can be implemented economically with a longer protocol when processing as few as 4–6 samples.

Automated liquid handling process

Fully automated systems require minimal human intervention, which means significantly less exposure to toxic fluids and no repetitive actions. For example, reliable and fast isolation of nucleic acids from variable samples is crucial for molecular analysis by polymerase chain reaction (PCR), reversed-phase (RT)-PCR, sequencing, arrays, and other methods. Automating magnetic bead-based nucleic acid extraction can reduce operator exposure to hazardous materials such as phenol or chloroform. Automated workstations can streamline protocols with a variety of different chemistries (i.e., from AGOWA, Life Technologies, Promega, and Omega-Biotek) and for different sample sources.

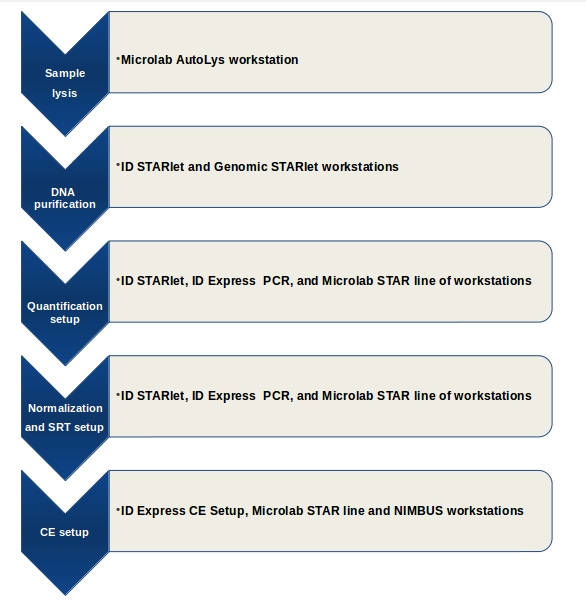

Figure 2 – The Microlab NIMBUS 96 automated multichannel pipetting workstation offers a high-density deck layout in compact footprint. The 96-channel CO-RE head provides a dynamic pipetting range from 1.0 μL to 1000 μL.

Figure 2 – The Microlab NIMBUS 96 automated multichannel pipetting workstation offers a high-density deck layout in compact footprint. The 96-channel CO-RE head provides a dynamic pipetting range from 1.0 μL to 1000 μL.Automated systems no longer need to be large and expensive. Bridging the gap between medium- and large-size labs is the benchtop Hamilton NIMBUS® workstation with optional safety hood (see Figure 2). This multichannel pipetting workstation is designed to automate sample preparation tasks that typically require a 96- or 384-well-plate format. The workstation is well suited for tasks such as DNA extraction from tubes, tube-to-plate reconfiguration, DNA quantification and normalization, as well as PCR prep and cleanup.

Larger, high-throughput systems have been around for more than a decade, but require significant capital investments. These systems are becoming more affordable with the advent of standardized solutions, and are capable of handling many routine and specialized applications right out of the box with minimal setup. Systems that previously took weeks or often months to set up can now be assembled and assimilated in hours and days without extensive training, thereby reducing even more risks associated with setup and downtime of larger instruments.

Safety solutions

Drug discovery

Drug discovery methods involve confirming the concentration of a dissolved compound, and technicians may need to dilute the solution, evaporate the solvent, and redissolve the compound in another solvent that is compatible with the mobile phase used for the particular LC/MS analysis method. Hamilton’s Anti-Droplet Control (ADC) feature enables accurate pipetting of volatile solvents such as methanol and acetonitrile without dripping. The enclosure of Hamilton liquid handlers can be equipped with a flange that allows a connection to the building exhaust system, effectively turning the liquid handler enclosure into a safety cabinet.

Through the integration of automation-friendly evaporators, the entire process of dilution, evaporation, and buffer exchange can be automated.

Forensic labs

Robotic arms and these larger platforms make it easy to integrate other routine jobs, such as next-generation sequencing (NGS), sample prep, ELISA, cell biology, genetic analysis, and PCR setup. The handling of forensic DNA samples for evidence, blood sample analysis, and compound sample prep, for example, would benefit tremendously from automation by lowering the stresses and chemical risks of manual liquid handling.

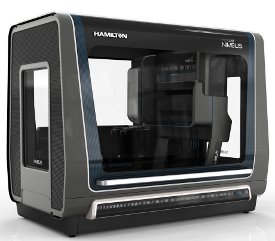

Figure 3 – The casework sample analysis has a set of very clear process steps known to all forensic scientists. A set of automated solutions developed by Hamilton Robotics helps scientists obtain the best-quality results while ensuring the reproducibility and traceability of each step in the process.

Figure 3 – The casework sample analysis has a set of very clear process steps known to all forensic scientists. A set of automated solutions developed by Hamilton Robotics helps scientists obtain the best-quality results while ensuring the reproducibility and traceability of each step in the process.Most U.S. forensic labs are backlogged and under pressure to guard the chain-of-custody of evidence samples. Automation of liquid handling not only reduces the physical stress of manual pipetting, but also reduces the added stress of protecting public safety. Too often, cases have been dismissed due to lack of reliable evidence. Workstations such as those mentioned here have software and instrumentation that can track the sample’s movement, providing prosecutors with proof that is less likely to be questioned. Hamilton offers a complete automated work flow for analysis of DNA evidence (see Figure 3).

Blood sample preparations

Figure 4 – The easyBlood workstation is a high-throughput, fully integrated workstation that enables technicians to reliably pipet the desired layer of primary blood samples, including the buffy coat.

Figure 4 – The easyBlood workstation is a high-throughput, fully integrated workstation that enables technicians to reliably pipet the desired layer of primary blood samples, including the buffy coat.Blood sample preparation for biobanking storage is another area that requires difficult extraction and handling techniques. Blood fraction layers (plasma, buffy coat, and red blood cells) are difficult to extract accurately and are critical for research applications. Automated pipettors, such as the Microlab easyBlood STARlet workstation (Hamilton) (Figure 4), eliminate strain on the eyes and mixing of the layers. The workstation employs state-of-the-art imaging technology to identify the desired layer of primary blood samples, including the difficult buffy coat.

The software tracks samples using barcodes, and robotics can integrate directly with automated biobanking systems, virtually eliminating physical human interaction. Hamilton provides automated storage systems such as the –20 ° C, SAM system, and the ultralow –80 °C BiOS high-capacity storage system that can be built to store more than 10 million samples and integrate with automated handlers both up and downstream of the sample management work-flow process.

Safety and security trends in liquid handling

We are seeing significant gains in bringing automation to small and large laboratories due to the desire to keep lab workers more productive and sample preparation more accurate. Eliminating much of the repetitive motion and other physical and mental strains from the lab ensures higher productivity and improves reliability of results.

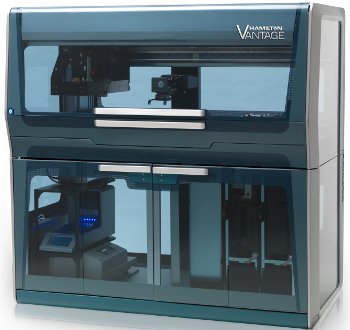

Figure 5 – The VANTAGE Rear Integration Cabinet module is a full-height integration space for the VANTAGE platform. It may be added to any system containing a pipettor, logistics cabinet, and track gripper, and is for the integration of third-party devices, entry/exit modules, or waste modules

Figure 5 – The VANTAGE Rear Integration Cabinet module is a full-height integration space for the VANTAGE platform. It may be added to any system containing a pipettor, logistics cabinet, and track gripper, and is for the integration of third-party devices, entry/exit modules, or waste modules.

There will always be larger and faster systems that eliminate more and more human intervention. Hamilton’s newest and largest liquid handler, the VANTAGE system (see Figure 5), provides a fully enclosed platform with vertically integrated workstations that maximizes space through high-capacity tip and plate shuttling from below the pipetting deck. It has a telescoping gripper that enables below-deck third-party device automation, eliminating the need for manual intervention, reducing physical stress and freeing time for analysis. Finally, wireless tablets with multitouch capabilities serve as remote access, virtual workspaces for location-free monitoring of the user’s application.

Automating one or more of a lab’s pipetting protocols improves technician safety and sample tracking and reduces errors. This permits laboratories to explore new applications faster, because they can program the methods into the device’s software.

The standardization of these workstations will also bring more consistency to lab results, making the tangible and intangible benefits outweigh the perceived cost savings when using manual pipetting resources.

Bobby Chavli is Associate Director of Marketing and Business Development, Hamilton Robotics, 4970 Energy Way, Reno, NV 89502, U.S.A.; tel.: 775-858-3000, ext. 540. Annette Summers is Sr. Editor/Founder, and Mary Napier is Scientific Writer and Researcher, GeneCom Group, San Francisco, CA, U.S.A.