Boron-doped diamond (BDD), a

working electrode material (ESA

Biosciences,

Chelmsford, MA)

developed for use with HPLC–electrochemical detection, promises to

open new areas for analysis with electrochemical detectors. Electrochemical

detection (ECD) with HPLC has

proven to be of significant value in measuring

biologically and clinically relevant

molecules. ECD detectors work

by applying a voltage between a working

and a reference electrode in a flow

cell. As molecules pass through the flow

cell, those that can be easily oxidized or

reduced at the applied potential react at

the working electrode, producing a flow

of electrons (Figure 1). The detector

(Figure 2) measures this flow of electrons.

With the electronics available

today, it is a highly sensitive measurement.

Only those molecules that will

oxidize (or reduce) at the electrode at

the applied potential are detected, thus

giving high selectivity. Because of the

inherent high sensitivity, selectivity,

and wide dynamic range of the technique,

it is used extensively in important

areas such as brain research and for

the diagnosis of specific cancers.

Figure 1 - In an electrochemical detector, a potential is applied between a working and reference electrode. The molecule of interest is oxidized or reduced at the working electrode. The result is a flow of electrons (current) that can be measured and quantified. This requires that the molecule be oxidized or reduced at the set potential.

Figure 2 - Coulochem III electrochemical detector (ESA Biosciences). The electronics control and hold the potential applied to the electrodes in the flow cell. The Coulochem III collects and processes the signal and sends it to the data station of an HPLC system.

Over the years, a number of materials

have been used for the working electrodes.

These include noble metals (such

as Au, Ag, and Pt) and various forms

of carbon (carbon paste, graphite, and

amorphous or glassy carbon). The carbon-based electrodes are considered general-purpose working electrodes and have

found extensive use in a broad array of

applications.1 All of these carbon-based

electrodes share a common microstructure

and demonstrate similar behavior.

Despite the high utility of such graphitic

and glassy carbon electrodes,

they are limited in the molecules they

can detect because of the restrictions

in the potential ranges that can be used

with such materials. (They may even

require high overpotential to produce a

response—some compounds simply do

not react well; other reactions actually

require the working electrode to take

part in the reaction mechanism, rather

than just acting as an electron source

or sink.) Additionally, some chromatographic

conditions and sample matrices

cause degradation in the electrode’s

performance that is not easily restored

during or following the analysis. This

is often the case resulting from

adsorption of contaminants in

the sample or even the analyte

onto the electrode surface. An

example of such an application

is the analysis of thiols and disulfides

in biological samples.

An ideal working electrode

that can extend the utility and

robustness of ECD would have

many of the properties of the

carbon electrodes but would be

able to operate at more extreme

(either higher or lower) potentials

than typical carbon-based

electrodes without suffering

from the high noise resulting

from oxidation of water in the

mobile phase.

During the 1980s, various forms of carbon

became widely used as electrodes

for general electrochemistry. This was

due to the simplicity of fabrication, the

relatively low cost, and the ability to

produce electrodes of high surface area.

The applications included electroanalysis,

energy storage devices, and electrosynthesis

and reaction, as well as flow

injection analysis and HPLC with ECD.

In the mid-1980s, techniques were

developed for low-pressure diamond

synthesis. Although diamond is a

mechanically resilient and strong material,

unfortunately, with its SP3 orbital

structure, it is notoriously inert and

unsuitable for use as a working electrode

material. Fortunately, methods became

available for the inclusion of metal dopants

in these diamond films, rendering

the inherently insulating diamond film

conductive. One such dopant is boron.

Typically, electrodes of boron-doped

diamond are constructed on a supporting substrate, often silica, glassy carbon,

or metals. The polycrystalline, thin film

is formed by chemical vapor deposition.

Considerable work has been published,

originally on the properties of

these materials and later on their use

in numerous applications. Pioneering

work in the early 1990s was conducted

by Swain2,3 and colleagues in

the U.S.A., and Fujishima4,5 and co-workers

in Japan. Despite the extensive

and impressive work of these

groups as well as others, the use of

BDD material for analytical electrochemistry

has remained primarily in

research laboratories.

The BDD electrode has several features

that make it a favorable working electrode

material for use in HPLC–ECD.

As previously noted, diamond itself is an

excellent insulator. When moderately

doped with boron, the material behaves

as a semiconductor, but at high levels of

boron doping, diamond takes on metal-like

properties, making it a suitable material

for a working electrode. BDD electrodes

have low capacitance, resulting in

lower inherent noise, a uniform surface,

high chemical and structural stability,

and resistance to fouling. When used

as an electrode, the BDD electrode can

operate with a wider range of working

potentials than glassy carbon.

Enhanced surface stability

The surface stability of the diamond

makes it resistant to surface modification.

It is common for thin-film carbon-based electrodes to change their

properties over time (e.g., oxygen termination versus hydrogen termination,

etc.), requiring extensive

polishing or electrochemical

processing to restore the original

behavior. Even at high potentials

the surface of the BDD working

electrode remains inert and has a

long working life without changing

its characteristics. Because of

the inherent characteristics of the

surface, there is little or no fouling

due to adsorption of contaminants

from the analyte or sample matrix.

“Chip” electrode design

Figure 3 - The BDD electrode is configured on a replaceable chip. The chip and gasket are placed in the cell body and are held in place with the pin assembly to make electrical contact and create a liquid seal in the flow cell.

To take advantage of the properties

of the BDD electrode, a thin-film

amperometric cell design was chosen.

The cell uses the ESA Biosciences

maintenance-free palladium reference

electrode. The BDD is deposited

on a wafer, which is then cut to

the proper size and shape. The wafer

is coated with a conductive backing

layer. This electrode chip is then

placed into the 5040 Analytical cell

(ESA Biosciences).

Contact with the

electrode and sealing against a gasket

is made with the pin assembly, which

makes continuous contact with the

working electrode (Figure 3). The

cell is then connected to and is controlled

by a potentiostat such as the

Coulochem

III detector.

Applications of the

technology

Thiols and disulfides are widely recognized

as biologically important molecules.

For example, glutathione controls the

potential of living cells and is involved in

the metabolism of drugs. However, our

knowledge of the role of thiols has been

hampered by the difficulty in generating

reliable analytical data. A number of

methods are available, including those

found in numerous publications describing

the use of HPLC–ECD. Although

electrochemical detection is a viable and

desirable detection modality, it has not

gained widespread use because of the problems

when using carbon electrodes. Thiols

are reactive and readily adsorb; disulfides

require a high potential and suffer from a

poor signal-to-noise ratio. Contaminants

in the mobile phase and sample matrix,

unless painstakingly removed, cause rapid

degradation of response.

Figure 4 - A hydrodynamic voltammogram is created for each compound as part of the methods development process. With the BDD electrode, the optimal potential for detection of 11 thiols, disulfides, and thioethers was found to be +1400 mV, well beyond the maximum operating potential of typical carbon electrodes.

Choosing the optimal potential for

oxidation of thiols, disulfides, and

thioethers requires the generation of

a hydrodynamic voltammogram. This

is done by injecting a given amount

of the compounds onto the HPLC–ECD system at different applied

potentials. The signal is then plotted

as a function of the applied potential,

and the optimal potential (typically where the response plateaus) is chosen.

The optimum applied potential

for this analysis is found to be +1400

mV (versus Pd reference) (Figure 4).

This is well within the potential window

of the BDD electrode but too

high for conventional glassy carbon

working electrodes.

The BDD demonstrates very good stability

over time and multiple runs. The

response is typically stable for at least

65 hr for standards with 1.5% RSD

for reduced glutathione (GSH) and

6.5% RSD for glutathione disulfide

(GSSG). Routine analyses of plasma

extracts do not adversely affect the

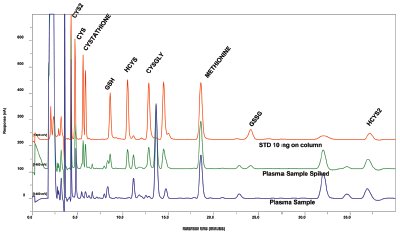

performance. Typical chromatograms

are shown in Figure 5.

Figure 5 - Typical chromatograms for standards, plasma with standards added, and normal plasma. With the BDD electrode, routine analysis of plasma sample showed no deleterious effects on the signal.

Technology that makes HPLC–ECD more useful

Despite the high sensitivity and selectivity

of HPLC–ECD, it has been

limited in the scope of addressable

molecules by the working electrode

material. The BDD electrode broadens

the range of molecules now addressable

by this technique. Unlike other

working electrode materials, BDD

electrodes do not suffer from fouling

and do not degrade when subjected to

prolonged high-oxidation potentials.

BDD is a robust and rugged working

electrode material, well suited to the

measurement of thiols and disulfides.

References

- Acworth, I.N.; Bowers, M. An

Introduction to HPLC-Based Electrochemical

Detection: From Single

Electrode to Multi-Electrode Arrays.

In Coulometric Electrode Array Detectors

for HPLC; Acworth, I.N., Naoi,

M., Parvez, H., Parvez, S., Eds.; Progress

in HPLC-HPCE; Volume 6, VSP:

Utrecht,

1997; pp 3–50.

- Swain, G.M.; Ramesham, R. Anal.

Chem.1993, 65, 345.

- Xi, J.; Granger, M.; Chen, Q.; Strojek,

J.; Lister, T.; Swain, G. Anal. Chem. 1997, 69, 591A–7A.

- Tenne, R.; Patel, K.; Hashimoto, K.;

Fujishima, A. J. Electroanal. Chem. 1993, 347, 409–15.

- Rao, T.; Fujishima, A.; Angus, J. Historical

Survey of Diamond Electrodes in

Diamond Electrochemistry; Fujishima,

A., Einaga, Y., Rao, T., Tryk, D., Eds.;

Elsevier: Amsterdam, 2005; pp 1–10.

Mr. Waraska is Manager, In Vivo Voltammetry,

ESA Biosciences, Inc., 22 Alpha

Rd., Chelmsford, MA 01824, U.S.A.; tel.:

978-250-7083; fax: 978-250-7087; e-mail:

[email protected]. Dr. Acworth is Vice

President, HPLC Products and Services, ESA

Biosciences, Inc., and Adjunct Associate

Professor of Pharmacology, Massachusetts

College Pharmacy, Boston, MA, U.S.A.