A molecularly imprinted polymer (MIP) film was fabricated using an electropolymerization technique after depositing carboxyl-functionalized multiwalled carbon nanotubes (MWNTs) onto a glassy carbon electrode surface. The molecularly imprinted sensor was tested by cyclic voltammetry and linear sweep voltammetry. The MIP-based sensor displayed excellent recognition capacity for uric acid compared to other structurally similar molecules. Additionally, the linear sweep voltammetry peak current was linear to the concentration of uric acid in the range from 2 × 10−7 to 8 × 10−5 mol/L, with a detection limit of 8 × 10−8 mol/L. The sensor was used successfully for the determination of uric acid in real samples, with recoveries ranging from 94% to 105%.

Background

Uric acid (UA) is the principal final product of purine metabolism in the human body,1 and is related to many disorders such as gout, hyperuricemia, and Lesch–Nyhan syndrome.2 The detection of UA in physiological samples using electrochemical techniques has been the subject of extensive interest because of its inherent advantages of simplicity, high sensitivity, and relatively low cost compared to conventional colorimetry and spectrophotometric methodologies.3 As a result, there has been great interest in this area, leading to the construction of various modified electrodes. Different modified electrodes, including molecularly imprinted polymers4 and nanoparticles,5 have been used for the determination of UA.

In this study, a novel MIP-based electrochemical sensor was fabricated by depositing carboxyl-functionalized MWNTs and electropolymerizing poly-o-phenylenediamine (oPD) in the presence of uric acid onto a glassy carbon electrode (GCE) surface. An electroactive substance, potassium ferricyanide, was used as the redox probe. Under the optimized conditions, the sensor exhibited good adsorption and high recognition capacity for UA.

Experimental

Chemicals

Multiwalled carbon nanotubes were obtained from Shenzhen Nanotech Port Co. Ltd. (Shenzhen, China). Uric acid (UA), dopamine (DA), phenacetin (PA), ascorbic acid (AA), adrenaline (AD), noradrenaline (NAD), o-phenylenediamine (oPD), and N,N-dimethylformamide (DMF) were purchased from Sigma-Aldrich (St. Louis, MO). All other reagents were of analytical reagent grade or higher, and double-distilled water was used for all solutions.

Preparation of modified glassy carbon electrode (MGCE)

The MWNTs (1 g) were treated as reported6 to obtain carboxylic acid-functionalized MWNTs (MWNTs–COOH). Prior to modification, the surface of the bare GCE was polished with a 0.3- and 0.05-μm alumina–water slurry in sequence, and thoroughly ultrasonically rinsed with ethanol and doubly distilled water for 5 min. A suspension of MWNTs–COOH (1 mg/mL) in dimethylformamide (DMF) was prepared by the dispersion of MWNTs–COOH using ultrasonic churning. The MWNTs–COOH layer was modified onto the electrode surface using a traditional dropping method. The electrode obtained is called the MGCE.

Figure 1 – Repetitive cyclic voltammograms during the electropolymerization of oPD (5.0 m

Figure 1 – Repetitive cyclic voltammograms during the electropolymerization of oPD (5.0 mM

) and uric acid (1.0 mM

): a) onto bare GCE and b) onto MGCE. Scan rate: 50 mV sec–1. Supporting electrolyte: N2-saturated PBS (0.05 M

, pH 7.0) containing 0.1 M

KCl. Scan circles: 20.Electrochemical measurements

Electrochemical experiments were performed on a CHI 800C workstation (ChenHua Instruments Co., Shanghai, China) with a conventional three-electrode system. Solutions were deaerated (using prepurified nitrogen) for 10 min before the electrochemical experiment.

Results and discussion

Electropolymerization

As shown in Figure 1, a broad and irreversible oxidation peak appeared with a peak potential at 0.6 V. The anodic peak current disappeared much more slowly compared to bare GCE and higher current densities were observed for o-phenylenediamine oxidation, confirming the higher electroactive area in MGCE. No notable differences were observed in the cyclic voltammogram with and without the presence of UA (not shown), which demonstrates that UA does not have any electroactivity on the MGCE under the chosen experimental conditions. Further, the structure of the template was not changed during the polymer synthesis around UA.

Electrochemical characterization of MIP-MGCE and nonmolecularly imprinted MIP (nMIP)-MGCE

Figure 2 – A) Cyclic voltammograms of: curve a) bare GCE, curve b) MGCE, curve c) MIP-MGCE before uric acid removal, curve d) MIP-MGCE. B) Curve e) MIP-MGCE before UA removal, and curve f) nMIP-MGCE; 1.0 mmol/L [Fe(CN)6]3– in N2-saturated PBS (0.05

Figure 2 – A) Cyclic voltammograms of: curve a) bare GCE, curve b) MGCE, curve c) MIP-MGCE before uric acid removal, curve d) MIP-MGCE. B) Curve e) MIP-MGCE before UA removal, and curve f) nMIP-MGCE; 1.0 mmol/L [Fe(CN)6]3– in N2-saturated PBS (0.05 M

, pH 7.0) containing 0.1 M

KCl. Scan rate: 50 mV sec–1.As shown in Figure 2a, a pair of typical redox peaks of K3[Fe(CN)6] appeared at bare GCE (curve a). When the surface was covered with the MWNTs–COOH layer, an increment of the redox peak current was observed (curve b). It is well known that MWCNTs–COOH have small dimensional size and excellent catalytic activity, which facilitated the redox reaction of Fe(CN)63–/4– at the MGCE.

When the imprinted film was electrosynthesized on the surface of the MGCE, the peak current was not observed (curve c). It is possible that the K3[Fe(CN)6] could not pass through the layer of polymer to arrive at the surface of the electrode. As shown in curve d, after the template removal, the redox current of Fe(CN)63− increased. This can be ascribed to the fact that once the template was removed, the formation of recognition sites or binding cavity made electronic transmission possible again.

Figure 3 – Molecular structures of uric acid (UA), caffeine (CA), theophylline (TP), adenine (AD), xanthine (XA), hypoxanthine (HXA), ascorbic acid (AA), and dopamine (DA).

Figure 3 – Molecular structures of uric acid (UA), caffeine (CA), theophylline (TP), adenine (AD), xanthine (XA), hypoxanthine (HXA), ascorbic acid (AA), and dopamine (DA).In contrast, for nMIP-MGCE, almost no peak current was observed (curve f in Figure 2b), which may be attributed to the fact that the nMIP film was polymerized in the absence of UA; therefore no cavities with binding sites were obtained. The results indicated that nMIP-MGCE was unable to recognize UA.

Performance of the imprinted sensor

Selectivity of the MIP-MGCE

Figure 4 – LSV curves of MIP-MGCE in 1.0 mmol/L [Fe(CN)6]3– after incubation in different concentrations of UA (from bottom to top): 0, 0.2, 0.4, 0.8, 2, 4, 8, and 20 μ

Figure 4 – LSV curves of MIP-MGCE in 1.0 mmol/L [Fe(CN)6]3– after incubation in different concentrations of UA (from bottom to top): 0, 0.2, 0.4, 0.8, 2, 4, 8, and 20 μM

. Supporting electrolyte: N2-saturated PBS (0.05 M

, pH 7.0) containing 0.1 M

KCl. Scan rate: 50 mV sec–1.The selectivity of MIP-MGCE to UA was evaluated by testing its linear sweep voltammetry (LSV) responses in the presence of some possible interfering substances (structures shown in Figure 3). The selectivity of the imprinted electrode to UA was evaluated by calculating the anodic peak current ratio (Is/I0), where Is and I0 are the anodic peak current of K3[Fe(CN)6] in the presence and absence of interfering substances. A tenfold excess of caffeine (CA), theophylline (TP), adenine (AD), xanthine (XA), hypoxanthine (HXA), dopamine (DA), and ascorbic acid (AA) over UA caused a minimal change in peak current: The peak current ratio varied only slightly, from 0.90 to 1.05. These results indicate that MIP-MGCE showed higher recognition selectivity for UA.

Calibration graph and detection limit

A linear relationship between the anodic peak current and UA concentration was obtained covering the concentration range from 2.0 × 10–7 to 2.0 × 10–5 M; the linear regression equation is Δi (μA) = 0.0644 +1.2632 C (μM) (current data obtained from Figure 4), with a correlation coefficient of 0.9997. The detection limit is calculated to be 8 × 10–8M based on the 3σ of the blank signals.

Reproducibility and stability of MIP-MGCE

The reproducibility of the measurements was evaluated by measuring the LSV responses of K3[Fe(CN)6] in the presence of 2.0 × 10–6 M uric acid at the same MIP-MGCE. The relative standard deviation (RSD) for seven successive determinations is about 3.5%. The response of the imprinted electrode decreased to 94% after storing for one week, and 90% of the original responses were retained after two weeks.

Determination of UA in human urine samples

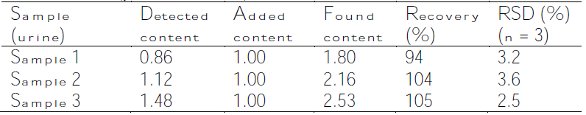

Table 1 – Determination of UA concentration in human urine samples using MIP-MGCE (µmol L–1, n = 3)

All of the samples were diluted 200 times with 0.05 M phosphate-buffered saline (PBS, pH 7.0) in order to fit into the linear range of UA determination. To verify the efficacy of the proposed method, the samples were spiked with UA solution, and the amount of UA was then determined. The results are shown in Table 1.

Conclusion

In this study, an MIP-MGCE formed by the cyclic voltammetric electropolymerization of an oPD film on MGCE was successfully fabricated. The proposed low-cost chemical sensor can potentially be applied to measurements of UA in physiological samples.

References

- Dutt, V.V.; Mottola, H.A. Determination of uric acid at the microgram level by a kinetic procedure based on a pseudo-induction period. Anal. Chem. 1974, 46, 1777.

- Yamanaka, H.; Togashi, R. et al. Optimal range of serum urate concentrations to minimize risk of gouty attacks during anti-hyperuricemic treatment. In: Purine and Pyrimidine Metabolism in Man Ix. Plenum Press: New York, NY, 1998, pp 13.

- Zen, J.M.; Kumar, A.S. et al. Recent updates of chemically modified electrodes in analytical chemistry. Electroanalysis 2003, 15, 1073.

- Po-Yen Chen, Vittal, R. et al. A novel molecularly imprinted polymer thin film as biosensor for uric acid. Talanta 2010, 80, 1145.

- Wang, X.; Wu, M. et al. Simultaneous electrochemical determination of ascorbic acid, dopamine and uric acid using a palladium nanoparticle/graphene/chitosan modified electrode. J. Electroanal. Chem. 2013, 695, 10.

- Zhang, Z.H.; Luo L.J. et al. A polypyrrole-imprinted electrochemical sensor based on nano-SnO2/multiwalled carbon nanotubes film modified carbon electrode for the determination of oleanolic acid. Electroanalysis 2011, 23, 2446.

Dr. Peng is a Senior Researcher, Department of Chemistry, Quanzhou Normal University, Bincheng Rd. 28, Quanzhou 362000, Fujian, PR China; tel.: +86 595 2291 9531; fax: +86 595 2291 9530; e-mail: [email protected]. The author is grateful for the financial support provided by the Science Foundation of Quanzhou, Fujian Province (grant no. 2012Z112).