Many biochemical assays involve the addition of different reagent fluids interrupted by delays or incubations to allow for a reaction to occur. Originally these assays were performed in test tubes, but they have since been converted to microplates as a means to reduce reagent volume and increase throughput.

ELISAs are ubiquitous in biomedical research and clinical testing. This heterogeneous assay typically uses a microplate as a solid surface to which specific antibodies are bound, permitting the capture and analysis of a seemingly infinite number of analytes. It does so by a series of incubations, reagent additions, and wash steps. During incubations, specific molecules are bound to the solid substrate by interactions with the previously absorbed antibodies. Following the binding step, unbound materials are removed by the washing step. After the unbound material has been removed, the next reagent (usually a conjugate) is added that is comprised of a specific antibody and an enzyme covalently linked. Again unbound material is removed and the next reagent (substrate) is added afterward. The substrate interacts with the enzymatic portion of the conjugate to produce a colored compound that can be detected by absorbance, fluorescence, or luminescence, depending on the substrate used. Regardless of the analyte, the same process steps are used in ELISA.

The EL406 Microplate Washer Dispenser (BioTek Instruments, Inc., Winooski, VT) is an automated microplate processor that can perform microplate washing steps in 1536-, 384-, and 96-well microplates. In addition to standard wash routines, it has built-in cell-washing capabilities. A buffer switching valve allows for up to four different wash buffers to be selected without changing bottles. A built-in ultrasonic cleaner enables automated maintenance of the wash manifold. In addition, the device has up to three different reagent dispenser heads. One head is a peristaltic pump device capable of dispensing from 1 μL to 3000 μL. The EL406 can also be configured with an additional module that has two independent syringe pump dispenser heads that can deliver from 3 μL to 3000 μL. The dispenser is capable of plate shaking at three different speeds and is robotic compatible.

The BioStack (BioTek Instruments) is a microplate handling and storage device that can hold up to 50 SBS standard height plates. A plate gripper lifts the microplate from the diving board of the device and places it on the carrier of the EL406. The BioStack sequentially delivers microplates from the bottom of the input stack to the EL406 and then receives them in the bottom of the output stack. The net result is that the first microplate to be processed will come from the bottom of the input stack and end up at the top of the output stack. Prior to subsequent processing, the stacks are moved from the output stack back to the input stack, a process called re-racking. In addition to resetting the microplates to be processed, this action also reorders them such that the first microplate to process is again on the bottom of the stack.

By using the BioStack as both an input/output storage device and an incubation location for the EL406, heterogeneous assays that involve the addition of reagents to, and the washing of, microplates can be automated. Liquid Handing Control™ (LHC™) PC software (BioTek Instruments) can be used to control both the BioStack and the EL406 and coordinate their actions. This allows for the automation of many assays that involve the addition and removal of fluids at timed intervals. This article describes the automation of the liquid handling portion of three different assays.

Avian influenza virus antibody ELISA

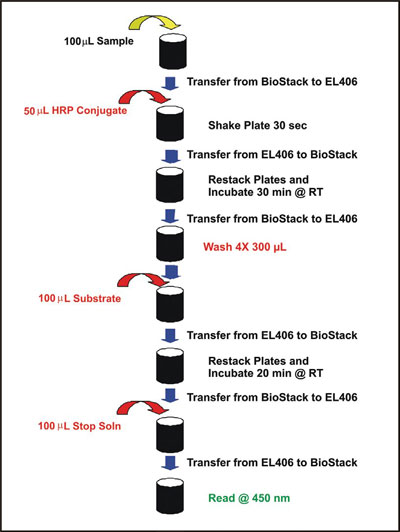

Figure 1 - Avian influenza virus antibody assay test procedure steps. The avian influenza antibody test used was an ELISA kit from Synbiotics and performed as described in the kit instructions. The absorbance of the wells at 405 nm was determined using a Synergy 4 Hybrid Multi-Mode Microplate Reader (BioTek Instruments). Processes carried out by the EL406 Microplate Washer Dispenser are indicated in red.

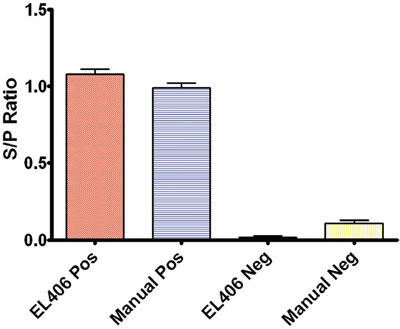

Figure 2 - Comparison of manual and semiautomated EL406 processing. Positive and negative kit controls were treated as unknown samples and the signal-to-positive control ratio (S/P) was calculated. Data represent a total of 72 samples of each from three different assay plates.

Avian influenza virus (AIV), a viral disease of domestic and wild birds, has a range of responses from almost asymptomatic to very high mortality. The Synbiotics ELISA kit (Kansas City, MO) is a specific screening test for the detection of antibody to AIV in chicken serum samples. The basis of the test is that serum from chickens exposed to AIV antigens will contain specific anti-AIV antibodies, which can then be captured on a test plate coated with AIV antigens through an antigen–antibody complex.

The screening of chicken flocks for AIV plays an important role in ensuring that bird flocks are disease free. The sheer number of animals that need to be tested under normal circumstances in many animal test facilities requires that large numbers of samples be processed daily. In the event of a disease outbreak, the test volume would be expected to increase many-fold above the current levels in specific regions. The ability to automate the process is a tremendous savings in time, labor, and cost. The BioTek robotic system was used to automate the liquid handling steps of the Synbiotics avian influenza virus antibody test kit (Figures 1 and 2).

Results

By semiautomating the AIV antibody detection assay with robotics and a combined washer dispenser, users realize time, labor, and cost savings compared to manual methods. In addition, since microplate movement and the automated process are controlled via LHC software, sources of error from human intervention are reduced, and consistency across multiple runs is increased. Very similar signal-to-positive control ratios are observed between manual processing and that of the EL406 semiautomated processing as well as similar well-to-well variability.

Melamine quantitation ELISA

Figure 3 - Melamine ELISA test procedure steps. The melamine assay used was an ELISA kit from Abraxis (Warminster, PA) and performed as described in the kit instructions. The absorbance of each well at 450 nm was determined using a Synergy 4 Hybrid Multi-Mode Microplate Reader. Processes carried out by the EL406 Microplate Washer Dispenser are indicated in red.

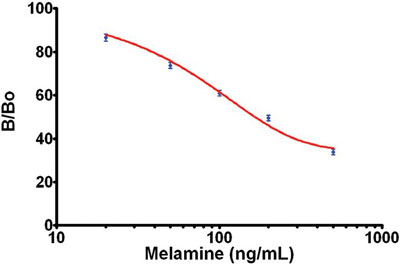

Figure 4 - Melamine concentration curve.

Melamine is a nitrogen-rich compound normally used as a flame retardant or in conjunction with formaldehyde to produce melamine resin, a durable thermosetting plastic used in the manufacture of countertops, fabrics, and glues. However, in addition to the normal use of melamine, several illicit uses for the material have been reported. The practice of using melamine scrap as an additive to animal feed and food products to give the appearance of increased protein content is widespread in many countries. Recently, a scandal in China1 implicated and even convicted several companies and individuals of knowingly adding melamine to milk and infant formula, leading to kidney stones and renal failure, and resulting in the deaths of several infants while sickening over 300,000 others.

The melamine assay is a competitive ELISA, where melamine–HRP conjugate competes for binding to the melamine antibody attached to the wells of a microplate. Following the completion of the binding reaction, unbound sample and conjugate are removed by washing. Substrate reagent is immediately added and the color allowed to develop. The color development reaction is terminated by the addition of stop solution, and the absorbance of each well is determined. Unknown concentrations are then determined by interpolating a standard curve generated by running standards of known melamine concentrations. In order to easily compare multiple experiments, the data are expressed as a ratio to the zero standard. This ratio is often expressed as B/Bo. An EL406 Washer Dispenser was used in conjunction with the BioStack and LHC software to semiautomate this ELISA application (Figures 3 and 4).

Results

By semiautomating the melamine quantitation ELISA with robotics and a combined washer dispenser, time, labor, and cost are reduced in comparison to manual methods. Additionally, because microplate movement and the automated process are controlled via LHC software, sources of error from human intervention are reduced, and consistency across multiple runs is increased. Melamine quantitation assay results are very similar to data reported with the ELISA kit insert with a five-parameter logistic fit B/Bo calculation. The competitive assay results using the EL406 Washer Dispenser and BioStack Microplate Stacker system also demonstrate decreasing signal in the detection range of 10–30 μg/mL with increasing melamine concentration per kit insert data.

Space- and time-savings

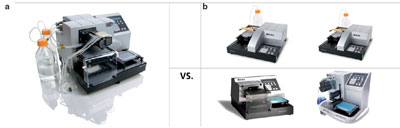

Figure 5 - Multicomponent manual assay and EL406 semiautomated systems. a) EL406 Washer Dispenser. b) The four instruments (ELx405 washer, MicroFlo Select dispenser, and two MicroFill dispensers) necessary to provide the equivalent capability of the EL406 Washer Dispenser.

Figure 6 - Schematic diagram of an automated ELISA Twister® II system (BioTek Instruments) with and without an EL406 Washer Dispenser. The necessary equipment to completely automate the avian influenza virus test kit process has been depicted using either individual components (a) or an EL406 Washer Dispenser (b).

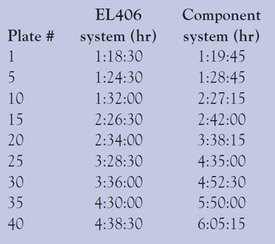

Table 1 - Simulated assay times for Synbiotics AIV antibody test kit

Laboratory bench space is a valuable asset that is often in short supply. Physically large instruments or the requirement for multiple instruments to perform assay functions leads to a crowded and cluttered work area that decreases productivity. Because the expense of adding new laboratory space is often cost-prohibitive, in order to improve productivity it is necessary to develop instrumentation that provides multiple functionalities in a compact package. The EL406 Microplate Washer Dispenser provides the same functionality as four individual instruments (ELx405 washer, MicroFlo™ Select dispenser, and two MicroFill™ dispensers, BioTek Instruments) in a footprint only slightly larger than that of the ELx405 washer it replaces (Figure 5). Even when a BioStack plate storage device is included with an EL406 (Figure 6), the footprint is considerably smaller than the combined footprint of four instruments. In addition to reducing footprint, the use of the EL406 Microplate Washer Dispenser will reduce assay times (Table 1) by eliminating the need to move plates between dispensers and washers.

Results

The EL406 Washer Dispenser provides the same functionality as four individual instruments with less overall cost and footprint. Additionally, robotic systems that utilize the washer dispenser are less complex to set up, operate, and manage, and save valuable laboratory space. By using an EL406 instead of individual components, the amount of time spent moving the microplates from one station to another can be significantly reduced (Table 1).

Conclusion

The EL406 combination Microplate Washer Dispenser provides ELISA and heterogeneous wash assay results equivalent to manual processes, along with additional benefits to improve laboratory productivity. It saves bench space and reduces complexity in an automated or semiautomated robotic system, and also saves time by eliminating microplate movement in these systems. Finally, the EL406 offers a significant cost savings when compared to separate instruments.

Reference

- Chinese milk scam duo face death. British Broadcasting Corporation, Jan 22, 2009; http://news.bbc.co.uk/2/hi/asia-pacific/7843972.stm; retrieved Feb 17, 2009.

The authors are with BioTek Instruments, Inc., P.O. Box 998, Highland Park, Winooski, VT 05404, U.S.A.; tel.: 888-451-5171; fax: 802-655-7941; e-mail: [email protected].