Expanded bed adsorption (EBA) was introduced in 1999 with adsorbents that were used for pressure-driven packed beds.1 These had densities in the range of 1.1–1.5 g/mL, which was not much higher than the feed suspension or eluting buffer. First-generation expanded bed adsorption applications had very narrow operating windows and were slow. However, EBA had intuitive appeal as the capture step in bioprocessing, since it was compatible with suspended solids. The existing scheme involving displacement chromatography in packed beds was not.

Figure 1 – Rhobust Flex expanded bed adsorption system for rapid capture of large proteins from cell culture and fermentors. A 10-cm-i.d. column can capture and release about 100 g of antibody in 1 hr.

Figure 1 – Rhobust Flex expanded bed adsorption system for rapid capture of large proteins from cell culture and fermentors. A 10-cm-i.d. column can capture and release about 100 g of antibody in 1 hr.In expanded bed adsorption, the adsorbent is placed in a vertical column with the inlet at the bottom. A stable expanded bed is achieved when the adsorbent particles are levitated by balancing gravity with the frictional force of the upwelling liquid according to Stokes’ law. In first-generation EBA, even at a low flow rate some of the adsorbent found its way into the waste vessel.

Over the intervening years, the advent of specialized high-density column packings (Rhobust® High Density Adsorbents)* coupled with improved column design has opened the operating window wide. The heavier particles were synthesized by encasing a dense tungsten carbide core with cross-linked agarose. Rhobust particles have a density of 3.5 g/mL, which enables use of flow velocities of 200–600 cm/hr. This corresponds to 4–12 mL/min in a 10-mm-i.d. column and 8–25 mL/min in a 20-mm-i.d. column. Faster flow means shorter cycle times.

The selectivity of the adsorbent particles depends on the ligands bonded to the agarose. Sulfonyl propyl groups selectively adsorb cations by cation exchange. Protein A uses bioaffinity chromatography to capture antibodies. A mixed-mode phase combines hydrophobic and cation exchange selection. The agarose layer is open on the exterior surface, which improves binding capacity. The exact density is tailored to provide expansion of 20-, 35-, and 50-cm-high beds and different column diameters. Rhobust EBA adsorbents have binding capacities similar to packed bed. Ion exchange and mixed-mode adsorbents can be regenerated with 1 M NaOH, and Protein A adsorbent with 0.1 M NaOH.

The instrumentation for EBA has also improved. For example, Figure 1 shows an integrated unit called the Rhobust Flex. This platform is designed for 10 to 60-cm-i.d. columns. For generation 2, the Flex utilizes a Rotating Fluid Distributor (RFD) that directs the incoming liquid downward against the end of the column. This flow produces sufficient agitation to prevent sediment buildup on the bottom.

Figure 2 – Expanded bed chromatography with 1- or 2-cm-i.d. columns. The pump forces liquid to flow upward in the column with sufficient velocity to levitate a fluidized bed of adsorbent particles. Suspended solids in the feed travel up and out of the column to waste. The product is selectively retained by the adsorbent. After washing away the last of the debris, the pump is switched to the displacer buffer for harvesting the product by displacement chromatography. The separation process is so gentle that when purifying feedstock from cell culture, recovered cells are often still viable.

Figure 2 – Expanded bed chromatography with 1- or 2-cm-i.d. columns. The pump forces liquid to flow upward in the column with sufficient velocity to levitate a fluidized bed of adsorbent particles. Suspended solids in the feed travel up and out of the column to waste. The product is selectively retained by the adsorbent. After washing away the last of the debris, the pump is switched to the displacer buffer for harvesting the product by displacement chromatography. The separation process is so gentle that when purifying feedstock from cell culture, recovered cells are often still viable.For smaller-scale separations, DSM designed nozzle columns with diameters of 1 or 2 cm. These columns are used with conventional laboratory instruments such as peristaltic pumps or AKTA series LC (GE Healthcare, Piscataway, NJ), as shown in Figure 2. The smallest of the nozzle columns (20 × 1 cm) has a capacity of about 150 mg of antibody. Capacity scales linearly with column volume (length × diameter) (Figure 2).

Solutions are key

The liquids are very important since the density and flow affect the bed expansion. A bed expansion of 2.0 (twice the settled bed height) is usually ideal. The expansion and wash liquid generally have the same composition as the sample solution but without the sample, of course. This may also be used for wash and regeneration after the displacement step in preparation for the next cycle. The feedstock can be the growth medium including the host cells. The displacement solution depends on the particular adsorbent. Often it is a buffer with a significantly different pH and higher ionic strength.

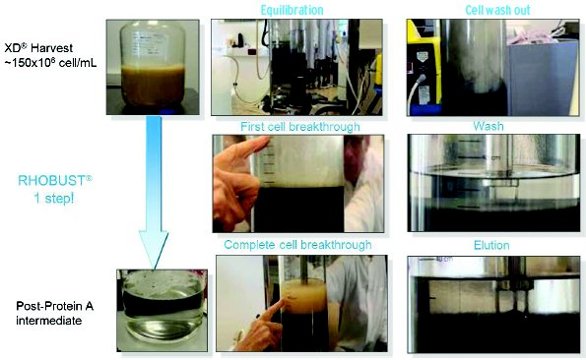

A typical EBA run is illustrated in Figure 3. The adsorbent is poured into the plastic column, with no need to pack the resin bed. Upward flow of buffer expands the bed as shown in “Equilibration.” The pump then starts pumping the sample suspension. Upon completion, the pump feed returns to the buffer. The important stages are “First cell breakthrough,” where the lightest cells (1 g/mL) and largest debris float up and out of the column. Pumping continues as light material is removed (“Complete cell breakthrough” and “Cell wash out”). Pumping continues on to provide a clear volume at the top of the column. Next, the displacement buffer is pumped into the bottom of the column to release the product. The product passes through the detectors and on to the collection vessel for further processing. The column is then regenerated.

Figure 3 – Operation of an expanded bed adsorption column. After the bed is stabilized, the sample is introduced. Solids including host cell debris pass upward through the fluidized bed. At the same time, the product is selectively adsorbed on the Rhobust Adsorbent of later release (see text).

Figure 3 – Operation of an expanded bed adsorption column. After the bed is stabilized, the sample is introduced. Solids including host cell debris pass upward through the fluidized bed. At the same time, the product is selectively adsorbed on the Rhobust Adsorbent of later release (see text).For repetitive cycles, the stages are easy to automate with a timer and liquid selection valve ahead of the feed pump. This EBA process replaces the capture stage of bioprocessing, which usually involves centrifugation, filtration, and displacement chromatography. Critical parameters of these processes are compared in Table 1.

Table 1 – Comparison of process parameters for packed bed and expanded bed adsorption of antibodies produced in Chinese hamster ovary (CHO) cells*

Results and discussion

As shown in Table 1, the properties of the product harvested from EBA and packed bed are comparable. However, EBA is faster since centrifugation, filtration, and column packing steps are avoided. Generally, the product can be processed without destroying the host cells, thus preventing intracellular contaminants from burdening the process.

Regulatory considerations for biotherapeutics

Over half the biotech therapeutic candidates in development are antibody based. The antibodies are produced usually by cell culture and occasionally by bacterial fermentation. The products are seldom unique molecular entities. They are large proteins with microheterogeneity in their primary, secondary, and higher order structures. The safety and efficacy of the drug will be evaluated based on the performance of the heterogeneous mixture. For any material to be considered a therapeutic candidate, the composition needs to be consistent from lot-to-lot. How consistent? That is a difficult question, but the regulators want to see negative results from a spectrum of tests that could show differences.

The FDA regulatory process for biotherapeutics is built upon results of clinical trials of a candidate material (i.e., for large-molecule biologics, it remains that “the product is the process”). Then, after marketing approval, the therapeutic is produced on a commercial scale. The commercial product is supposed to be a mimic of the material used in the clinical trials. If a problem occurs, the FDA often asks, “How does the suspected problem product compare with the material used in clinical trials?” The EBA process scales linearly by column volume from lab to pilot to production. Thus, one has a strong case to show that the product is consistent through clinical trials to and during postmarket surveillance.

Rapid cycles minimize exposure to proteases

For feeds that require lysis, such as fermentation broth, reducing the time the product is in contact with the proteases and glycosidases improves yield and, in some cases, product consistency. With EBA, proteases are usually removed during the cell washout step, which can be shorter than 30 min. Affinity purification with Protein A columns is usually effective in retaining the antibodies. Plus, immobilized proteins are often protected from proteolysis.

Enzymatic degradation is probably not uniform across all the antibody variants. There is concern that some members of the product fraction could be more degradation-resistant than others. Thus, the population profile could change during the processing and hold times. A change in population profile could change efficacy and possibly even safety. Good purification schemes therefore favor rapid processing, since it improves yield and also may avoid selective degradation.

Compatibility with high-density production

DSM is a contract manufacturer of therapeutic-grade intermediates and products.The company is committed to continuous innovation to provide more efficient and sustainable manufacturing solutions for the future of pharmaceuticals. The firm has developed process technology that improves yield by increasing cell density. However, higher biomass and yield increased viscosity, which caused problems in the capture step. Dilution was a workaround, but reconcentration of proteins downstream is undesirable for several reasons, including risk of aggregation.

Rhobust proved to be the ideal companion to the high-density harvest by separating the protein from the raw cell culture and supernatant in one process step. DSM acquired full ownership of the technology, and continues to commercialize Rhobust.

Benefits of EBA for bioprocessing

Expanded bed adsorption offers many practical advantages for bioprocessing, including speed and scaleability. The technology is different from standard LC, but with the improvements in EBA 2.0, it can be implemented with common laboratory apparatus, especially on the small scale. For large-scale bioprocessing, engineers can select optimized unit modules with a scale consistent with the rest of the purification scheme.

Reference

- Anspach, F.B. J. Chromatogr. A1999, 865, 129–44.

*EBA was first developed by UpFront Chromatography (Copenhagen, Denmark). In 2010, DSM (Heerlen, The Netherlands) acquired commercial rights to the technology. DSM licensed EBA to UpFront for all applications except bioprocessing.

Robert L. Stevenson, Ph.D., is a Consultant and Editor of Separation Science for American Laboratory/Labcompare; e-mail: [email protected].