Environmental concerns to limit and minimize sulfur in crude oil and petroleum fuels are continuing to spread to many regions of the world, requiring new standard test methods and modern instrumentation to meet the regulatory limitations on sulfur content and sulfur emissions. Energy dispersive X-ray fluorescence (EDXRF) is a technique widely used in the industry for sulfur measurement, as well for measuring other elements present in oils and fuels. New standard test methods for measuring ultra-low sulfur diesel (ULSD) include ASTM D7220, using monochromatic EDXRF instrumentation, and ISO 13032, a performance-based test method that includes the use of EDXRF systems. Demands in the crude oil industry have expanded and include the need to analyze for the possible presence of chlorine as well as sulfur. In the shipping industry, the latest marine pollution (MARPOL) regulations further reduce the allowable sulfur content in bunker fuels, as more sulfur emission control areas (SECAs) are established around the world’s major ports.

ULSD

Emission standards requiring the use of ULSD have been in place in many countries, including the Nordic region, Europe, North America, and Asia. These and other regions of the world continue the push for lower sulfur levels in diesel and other fuel oils based on regulatory guidelines in the U.S.A. and the Euro IV and V emission directives, as well as the new Euro VI directives expected to be in place in 2014. ULSD regulations limit the maximum allowable sulfur content in diesel to 10–15 mg/kg at the pump, depending on the global region. New international standard test methods to meet the ULSD measurement challenges include ASTM D7220 and ISO 13032.

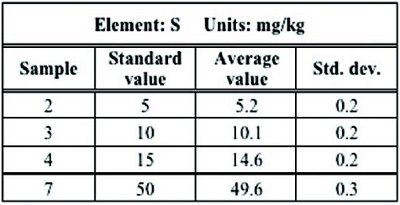

Table 1 – Results from Rigaku NEX CG EDXRF analyzer using polarization, 10 repeat measurements of each sample using 300-sec measurement time per analysis, as per ASTM D7220

ASTM D7220 is a test method utilizing monochromatic EDXRF instrumentation. In this test method, the use of an X-ray excitation target virtually eliminates background interference while producing a single energy of excitation ideal for ultra-low measurements of sulfur. In some instrumentation this target, along with a specific optical geometry, produces polarized X-rays, further reducing background interference. Using ASTM D7220, the performance of monochromatic and polarized excitation allows for reliable sulfur measurement down to 3 mg/kg, with a typical sulfur detection limit of 0.5 mg/kg using polarized monochromatic EDXRF. Table 1 shows typical precision results for the sulfur measurement using the NEX CG EDXRF analyzer from Applied Rigaku Technologies (Austin, TX).

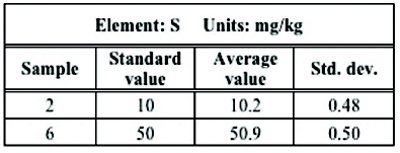

Table 2 – Results from Rigaku NEX QC+ EDXRF analyzer using direct excitation and SDD, 10 repeat measurements of each sample using 300-sec measurement time per analysis, as per ISO 13032

ISO 13032 is a new standard test method published in April 2012 that incorporates performance-based criteria requiring a system to meet thresholds for signal-to-background and precision. Benchtop EDXRF systems using direct excitation and a silicon semiconductor detector can meet these criteria and can be used for reliable measurement of sulfur down to 8 mg/kg as described in the scope in the method. Table 2 shows typical precision results using the Rigaku NEX QC+ EDXRF analyzer equipped with a silicon drift detector (SDD). A sulfur detection limit on the order of 1 mg/kg can be obtained, depending on measurement time used.

Sulfur content of crude oil

Because of the demands to lower the sulfur content in fuel oils, the sulfur content of crude oil affects the price and usefulness of crude. Less expensive high-sulfur “sour” crudes are often blended with the more expensive “sweet” crudes to provide the optimum feedstock at the refinery. The levels of sulfur in sweet and sour crudes are much higher than in the finished fuel oils and are easily measured with EDXRF instruments using such international test methods as ASTM D4294, ISO 20847 or 8754, IP 496 or 336, and JIS K 2541-4.

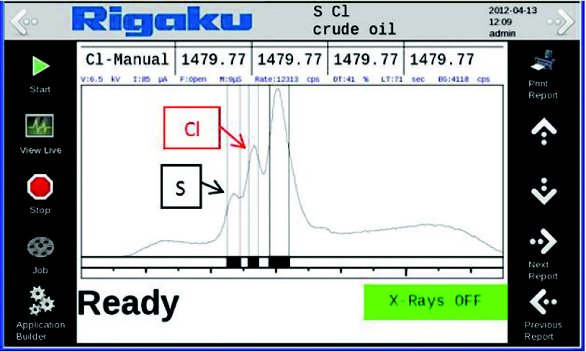

However, because of the high prices of crude oil and the need for the most efficient refining, the possible presence of chlorine in crude oils has become a concern in the industry. Chlorine may occur naturally at low levels in crude, but can also be introduced at higher levels by sea water in crudes from off-shore drilling, in solvents used in the refining process, and even through unwanted adulteration of crudes. Left undetected, the presence of chlorine has the potential to bias a sulfur measurement, resulting in an unreliable sulfur result. Modern low-cost EDXRF systems using a silicon semiconductor detector have the ability to distinguish the sulfur and chlorine measurements peaks, affording a corrected sulfur result. The chlorine concentration may also be simultaneously determined, if needed. The spectra shown in Figures 1 and 2 illustrate this idea. Detection and correction for the presence of chlorine are critical to many refining operations.

Figure 1 – Spectrum from Rigaku NEX QC using a semiconductor detector; sweet crude containing no chlorine.

Figure 1 – Spectrum from Rigaku NEX QC using a semiconductor detector; sweet crude containing no chlorine. Figure 2 – Spectrum from Rigaku NEX QC using a semiconductor detector; sweet crude containing chlorine contamination.

Figure 2 – Spectrum from Rigaku NEX QC using a semiconductor detector; sweet crude containing chlorine contamination.Refining X-ray transmission and EDXRF systems to meet MARPOL Annex vI directives

Figure 3 – Schematic of the Rigaku NEX XT X-ray transmission on-line process gauge, which achieves a sulfur detection limit of 45 mg/kg.

Figure 3 – Schematic of the Rigaku NEX XT X-ray transmission on-line process gauge, which achieves a sulfur detection limit of 45 mg/kg.In the 1970s, the International Maritime Organization (IMO) formed its ship pollution rules at the International Convention on the Prevention of Pollution from Ships, known as MARPOL 73/78. Since then, the allowed sulfur content of bunker fuels has continued to decline in the open seas and in areas referred to as sulfur emission control areas. SECAs are defined protected areas in which only low sulfur bunker fuels and marine diesels can be used. In August 2012, SECAs were established for the U.S. and Canadian ports, continuing the expanding global requirements for low sulfur bunker fuels to reduce pollutant emissions in ports as well as on the open seas.

Around the world, bunker fuels are monitored and blended to create fuels low in sulfur to meet the demands of the global shipping industry and the expansion of SECAs, as more regions adopt MARPOL regulations. To meet the analytical challenges enabling the reduction of sulfur in bunker fuels, X-ray transmission (XRT) systems and EDXRF benchtop analyzers have been modernized and refined.

Today, the X-ray transmission technique is embodied as a compact and rugged total sulfur process gauge that monitors hydrocarbon oils on-line and in real time. XRT can be used in many areas, including onboard ships in-line with the flow of fuel, at fuel blending facilities, bunkering stations and barges, as well as pipelines and at the refinery (see Figure 3).

Low-cost benchtop EDXRF, as described previously, is often used in conjunction with XRT systems as a way to validate sulfur trends measured on-line by XRT, and can be used to relate them to ASTM D4294 or other comparable international norms.

Conclusion

As global regulations continue to reduce the allowable sulfur content of petroleum oils and fuels, modern instrumentation has been adapted to meet the various analytical challenges. Benchtop EDXRF systems now incorporate semiconductor detectors, enabling the reliable measurement of sulfur from percent levels down to 3 mg/kg while expanding the analytical capability to multielement analysis. On-line XRT devices now allow measurements to be made in-line with the flow of oil, delivering reliable real-time sulfur measurements for refining as well as bunker fuel blending and dispensing. Modern EDXRF and XRT systems are important tools in the environmental efforts to limit sulfur, from transportation and refining of crude to blending and validation of bunker and diesel fuels.

Scott Fess is Product Manager, EDXRF, Applied Rigaku Technologies, Inc., 9825 Spectrum Dr., Bldg. 4, Ste. 475, Austin, TX 78717, U.S.A.; tel.: 512-225-1796; fax: 512-225-1797; e-mail: [email protected].