An all-digital cantilever controller for magnetic resonance

force microscopy (MRFM) was developed through

a close collaboration between SC Solutions (Sunnyvale,

CA), Cornell University (Ithaca, NY), and the

U.S. Army Research Laboratory (Adelphi, MD). The

advantage of an all-digital controller is its absence of

thermal drift as well as its great tuning flexibility. The

versatile controller comprises a field-programmable gate

array (FPGA) connected via a low-latency interface to

an analog input, an analog output, and a digital signal

processor (DSP) with additional analog outputs. Performance

of the controller was demonstrated in experiments

employing ultrasensitive silicon microcantilevers

fabricated at Cornell University’s Nanoscale Science

and Technology Facility.

The scientific questions we can ask are largely determined by

the quality of characterization technology available. In the

1980s, the scanning tunneling microscope (STM) generated

tremendous excitement because it enabled one to “see” and

manipulate individual atoms and molecules at a surface for

the first time, opening the door to resolving long-standing

questions about surface bonding, reactivity, and catalysis

at metal and semiconductor surfaces. The invention of the atomic force microscope (AFM) (and related scanned probe

microscopes) brought nonconductive surfaces

into view.1 The resulting ability to generate

nanometer-resolution surface maps of chemical

forces, magnetization, and charge has revolutionized

materials science.

The invention of the magnetic resonance

force microscope by John Sidles in 1991

offered scanned probe microscopy two exciting

new analytical capabilities: imaging subsurface

features and imaging with unambiguous

isotopic chemical contrast.2–4 Pushed to its

limit, MRFM has the potential to obtain the

full three-dimensional structure of any single

molecule. Such progress would be a revolutionary

advance, if it can be realized.

Imagine the scientific puzzles that could be

addressed with a “molecular microscope” capable

of nondestructively imaging the coordinates

of all the protons in any single molecule.

Such an instrument would allow us to form a

three-dimensional picture of any single protein,

in situ, with all of its post-translational

modifications in place.

- It would enable us to obtain the full structure of any

membrane protein and we could look at any cell’s outer

membrane with all the proteins and lipids frozen in

action together

- It would allow us to focus study on just the reactive part of

a molecule or a suspected binding site in a protein. Such

an instrument would open the door to studying impure

samples, samples that can be isolated in only small quantities,

and transient complexes

- It would permit us to study the conformational heterogeneity

among an ensemble of proteins in situ.

The magnetic resonance force microscope is a sensitive

new technique for detecting nuclear magnetic moments

(and unpaired electrons).5,6 MRFM is providing researchers

the unprecedented ability to acquire, nondestructively,

a three-dimensional image of subsurface nanoscale

features with isotopic selectivity. The instrument will be

invaluable to researchers and product developers in the

semiconductor, materials, and biotechnology industries.

The goal of the research reported here was to develop

an all-digital cantilever controller for a prototype magnetic

resonance force microscope capable of ultimately

detecting the nuclear magnetic resonance signal from one

proton. The paucity of tools for imaging materials with nanoscale resolution is presently a significant barrier to

the development of such technologies. The research summarized

here represents a significant step toward development

and commercialization of a magnetic resonance

force microscope for studying organic material at the

nanoscale.

Cantilever control

Within scanned probe microscopy (SPM), active control of

the cantilever is needed for several reasons:

- Fast damping of the cantilever is needed to increase imaging

speed in AFM. Cantilevers with a high quality factor

have lengthy ring-down time (many tens of seconds) that

slows imaging

- AFM imaging with constant frequency and/or imaging

with constant amplitude will provide different images.

Both types of imaging require feedback control

- In MRFM mode, the cantilever thermomechanical oscillations

can be many nanometers. These random oscillations

must be damped to below 0.1 nm rms if atomic-scale

imaging resolution is to be achieved

- As the cantilever approaches a surface, its natural frequency

can change significantly. For many applications,

it is favorable or required to track and measure the cantilever

frequency continuously.

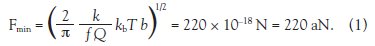

To accommodate these requirements, a generic cantilever

controller was proposed, as shown in Figure 1.

Figure 1 - Schematic of generic cantilever controller, including low-level motion controllers, as well as high-level characterization and detection algorithms.

Current analog cantilever controllers suffer from significant

thermal drift and are not easily tunable.7–10 To overcome

this, an all-digital cantilever was developed that

combines frequency shift measurements, phase shifting

and amplitude control, as well as positive feedback control

for driving the cantilever at resonance frequency.11–13

The versatile controller comprises a field-programmable

gate array connected via a low-latency interface to an

analog input, an analog output, and a digital signal processor

with additional analog outputs.

Hardware design

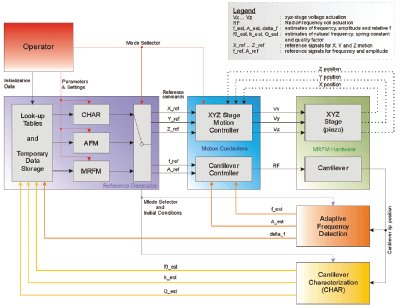

For the feedback controller, a C6711 DSP-based system

(Texas Instruments, Dallas, TX) tightly coupled to a

Virtex-II FPGA (Xilinx, San Jose, CA) was chosen. The

FPGA communicates directly through digital data lines to

a fast (80-MHz) analog-to-digital converter (ADC) and

digital-to-analog converter (DAC).

Figure 2 - Block diagram of cantilever controller. The scanned probe microscope provides a cantilever position signal, digitized at 80 MHz by the ADC, which passes it to the FPGA. The FPGA sends a phase-shifted AC signal to a fast DAC, which is used to drive the cantilever at its resonance frequency, thus closing the control loop. A DSP is used to set registers in the FPGA as well as control slow DACs.

As can be seen in Figure 2, the signal path is SPM—ADC—FPGA—DAC—SPM. The scanned probe microscope system

provides a signal that is proportional to a cantilever position. The

ADC digitizes this signal at 80 MHz and passes it to the FPGA.

The FPGA computes an estimate of the cantilever’s frequency,

amplitude, and phase. It also sends a phase-shifted AC signal to

a fast DAC, which is used to drive the cantilever at its resonance

frequency, thus closing the control loop. By using the FPGA to

perform all the calculations in the critical path of the control

loop, the overall system latency is reduced by eliminating the

need to pass data to and from the DSP over its input/output bus.

Figure 3 - Photograph of controller hardware installed at Cornell University. The stacked FPGA/DSP cards can be seen slightly right from the center.

The DSP controls the FPGA by setting the values of several

registers in the FPGA that determine the characteristics

of the control loop. The DSP also sets the values in three

slow (1-MHz) DACs. The slow DACs will be used for other

aspects of the scanned probe microscope. One is used to produce

a voltage proportional to the cantilever frequency, and

another controls RF power levels. This leaves the third DAC

free to control, for example, the height of the cantilever.

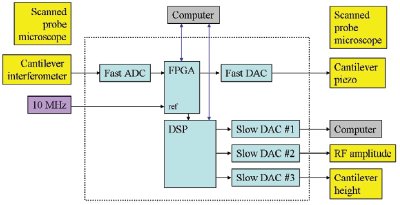

The 10-MHz clock reference for the ADC/DAC is externally

provided from a stable, low-phase-noise crystal. The

FPGA multiplies the 10 MHz up to 80 MHz using a digitally

locked loop (DLL), and this 80-MHz signal becomes the

clock for the ADC/DAC. The authors chose to provide the

10 MHz from an external source instead of using a DSP-generated

clock reference to guarantee that the reference

had low-phase noise. To obtain the rated accuracy of the

ADC/DAC, low-phase-noise clocks must be used. A photograph

of the completed all-digital cantilever controller

hardware is shown in Figure 3.

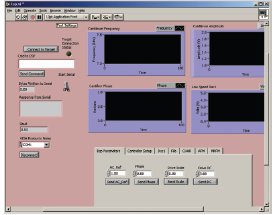

Figure 4 - Screenshot of the LabVIEW user interface (National Instruments, Austin, TX), which controls the hardware by setting control registers in the FPGA. The software also monitors the estimated frequency shift of the resonating cantilever.

Software interface

Figure 4 shows the main user interface. Key features are the

selection of the mode of operation, the display of relevant

data, e.g., the current estimate of the cantilever frequency

and/or frequency shift, as well as the magnitude of the cantilever

signal. Another feature is setting up the connection

with the target.

Figure 5 - Apparatus used to test the cantilever controller. a) Photograph of the scanned probe microscope head, b) schematic showing the cantilever approaching the surface in a perpendicular orientation to avoid snap-in to contact, and c) SEM of the cantilever. The scale bar is 10 μm.

Experimental setup

The experimental setup is shown in Figure 5. A custom-fabricated

silicon cantilever with resonance frequency of

roughly 7 kHz was brought within a distance d of approximately

5 μm of a gold surface. This is far enough away from

the surface that the cantilever is not affected by van der Waals

forces or friction, but close enough so that the cantilever

frequency can be shifted by applying a voltage Vtip between

the cantilever and the gold substrate. In the following experiments,

the voltage Vtip was stepped up to induce a frequency

shift that mimics an MRFM signal from nuclear or electron

spins below the sample surface. In this way, we can fully demonstrate

the performance of the digital cantilever controller

by detecting small frequency shifts without having to set up

a full MRFM experiment. The cantilever parameters were

spring constant—k = 7.4 × 104 N/m, resonance frequency: f =

7373 Hz, and quality factor: Q = 2.8 × 104. The operating conditions

were—temperature: T = 300 K, pressure: P ~ 1 × 106

Torr, rms cantilever drive amplitude: zrms = 55 nm, and detection

bandwidth: b = 5 Hz. Under these operating conditions,

the minimum detectable force is calculated to be: