When the Montgomery County Crime Laboratory in Rockville, MD, needed a high-purity water system for a new laboratory area, a compact system that would supply Type I water from tap-water feed was chosen.

Part of the County’s police department, the Crime Laboratory is a small forensics lab with five DNA analysts who analyze evidence for the presence of biological stains. Once proper samples are obtained for comparison, the analysts conduct DNA analysis on these stains to obtain DNA profiles. The profiles are then compared to determine if a suspect could be the source of the profiled DNA obtained from an item of evidence. If a suspect has not yet been identified or an identified suspect has been eliminated, the DNA profile obtained from the evidence can be entered into the DNA databank for possible matches to convicted offenders, arrestees, or other crime scene samples.

There are three main steps involved with forensic DNA typing: DNA extraction; amplification, also known as polymerase chain reaction (PCR); and the actual DNA typing (electrophoresis step). After the laboratory extracts the DNA from the sample and quantitates how much DNA is present, the sample is amplified using a special kit that targets 16 areas on the DNA analyzed (this includes the FBI’s 13 core loci). The PCR procedure makes millions and millions of copies of those specific areas on the DNA so the laboratory can perform the DNA typing procedure. DNA typing is an electrophoresis process: The laboratory performs capillary electrophoresis using a genetic analyzer instrument that separates the DNA fragments based on their size. The laboratory uses the data obtained from the capillary electrophoresis step to generate a DNA profile for a sample.

The need for high-purity water

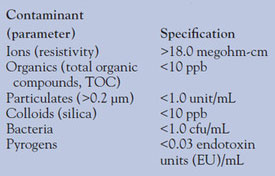

Table 1 - ASTM Type I water specifications

The laboratory requires American Society for Testing and Materials (ASTM) Type I water to prepare a buffer for the genetic analyzer, and also to rinse glassware before autoclaving. Table 1 shows the specifications for ASTM Type I water. Also referred to as ultrapure water, Type I water contains extremely low levels of ions, bacteria, organics, and particulates. If not removed, contaminants such as bacteria and enzymes such as DNase can destroy or degrade DNA. To remove these, the water must be treated with a combination of technologies to meet the laboratory’s final purity level.

There are many laboratory water systems available today that combine a number of technologies in one compact unit. The Montgomery County Crime Lab chose two PURELAB* Option-Q systems (Siemens Water Technologies, Warrendale, PA). The laboratory had been using older systems from another water treatment vendor, but liked the fact that the new system provides Type I quality in a space-saving, compact design with pretreatment and final polishing in one system. Having both purification steps in one box eliminates the need for additional pretreatment, reducing costs and saving valuable laboratory space.

The laboratory was already using Siemens Water Technologies to service its older systems. When the two new systems were purchased, a service agreement on those units, which covers preventive maintenance and any needed services, was also obtained. The water treatment system incorporates reverse osmosis (RO), deionization (DI), and ultraviolet sterilization technologies, as well as submicron filtration. It produces up to 15 L/hr of high-purity water direct from the tap and dispenses it at a flow rate of 1.0 L/min. A microprocessor continuously monitors the water purity level, and the water is recirculated through the system and storage tank (docking vessel) in order to maintain quality. When not in use, the system recirculates 10 min every hour to eliminate the potential for stagnant water and reduce the risk of bacterial contamination and biofilm. The water treatment system is contoured to fit into the docking vessel, thus reducing the overall footprint.

The system flow path is as follows: Tap water enters the water treatment system and flows through external and internal pretreatment cartridges to remove chlorine and particulates. The water then flows into the RO membranes, where organics, total dissolved solids, and bacteria are substantially reduced. The RO permeate is then fed to a 25-L docking vessel. The resulting prepurified water is pumped from the reservoir (docking vessel) through a dual-wavelength (185-nm and 254-nm) ultraviolet sterilizer, which disinfects the water and reduces organic levels. The water passes through the deionization cartridge pack, removing oxidized organics and remaining ions, and is finally passed through an absolute 0.2-µm point-of-use filter (purchased as an option with the system). A remote dispensing gun allows laboratory personnel to draw water either at the system or through the gun, offering them greater flexibility with their dispensing.

The first high-purity water system was installed in the Crime Lab in September 2007 and the second in December 2007. The laboratory reports that the systems have worked out well, citing the fact that they are small, take up minimal space, and supply consistent 18.2-megohm-cm water quality, which provides peace of mind.

Ms. Witham is Senior Technical Writer, Siemens Water Technologies, 10 Technology Dr., Lowell, MA 01469, U.S.A.; tel.: 978-614-7198; e-mail: [email protected]. For more information, visit www.siemens.com/lab-water.

*PURELAB is a registered trademark of ELGA LabWater.