The University of Washington (UW) is a leading public research and educational institution, with its largest of three campuses located in Seattle and adjacent to Lake Washington. With more than 40,000 students, 5500 faculty, and over $1 billion annually in academic and research funding, the UW is one of the nation’s largest public research universities. In addition, it is recognized as a leader in sustainability, as evidenced by its top ranking by the Sustainable Endowments Institute’s 2008 College Sustainability Report Card. The Seattle campus has over 3.1 million ft2 in faculty and staff offices, some of which were erected more than 50 years ago without mechanical conditioning. However, much of the office space built since then has included mechanical conditioning, and the university expressed interest in investigating whether the research offices in the new Molecular Engineering Building (MEB) could deviate from this de facto standard.

Climate studies

Figure 1 - Annual temperature and humidity analysis for Seattle Boeing TMY3. Image courtesy of ZGF Architects LLP (Seattle, WA).

Figure 1 - Annual temperature and humidity analysis for Seattle Boeing TMY3. Image courtesy of ZGF Architects LLP (Seattle, WA).The Seattle climate is almost unparalleled in the United States for its suitability for natural ventilation. A typical year (as documented by the Seattle Boeing Field TMY3 climate data file) has less than 85 hr of temperatures above 80 °F. In addition, summer days are typically dry, with rain showers rare and relative humidity typically less than 60% (see Figure 1). Analysis of site-specific climate data, provided by UW’s Department of Atmospheric Sciences located adjacent to the MEB site, confirmed these conclusions and suggested another opportunity for natural ventilation: When temperatures did exceed 78 °F, wind speeds surpassed 2 mph more than 95% of the time, and were virtually always from the northwest, providing the necessary air movement to remove accumulated heat and provide additional occupant comfort through evapotranspiration.

Using the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) adaptive comfort analysis for the Seattle TMY3 field, the team found that maintaining interior temperatures within 3 °F of exterior ambient temperatures would result in occupant comfort for over 97% of occupied hours. This analysis suggested that natural ventilation was a viable approach if architectural and mechanical systems were developed to support it.

Siting and project phasing

One initial challenge was the designated site of the MEB. For funding and development purposes, the project was divided into two phases that would meet at right angles and complete an academic courtyard on the UW campus. Consequently, siting and construction phasing issues necessitated that the primary façades of the first phase orient to the east and west (actually ENE and WSW, since the quadrangle is rotated 26° from true north). Because this dedicated research facility required a tight adjacency between researchers’ offices and their laboratories (separated only by a glass partition), cross-ventilation through the offices could not be employed. Instead, a strategy of stack ventilation allows air to be pulled through the offices without interfering with the mechanical ventilation and operations of the laboratories.

Initial schemes located the laboratories on the east side of the building, facing the quieter courtyard, while the associated faculty offices would face west, enjoying the longer views to the west. However, practical considerations related to natural ventilation necessitated a reversal of this scheme. Stevens Way, a campus arterial that serves bus and truck traffic, is located immediately to the west, and associated noise and pollution from this traffic would interfere with natural ventilation. The scheme reversal had another advantage: A western orientation would mean that peak solar radiation would coincide with peak afternoon temperatures, making occupant comfort more difficult to achieve. The laboratories, with their required high air changes, were much better equipped to deal with this condition.

Design development and technical analysis

At the beginning of design development, a full-day charrette was held in order to focus the development of this strategy. The workshop was led by Michael Hatten of Solarc Architecture and Engineering, a mechanical engineer with expertise in building simulation, climate responsive design, and passive design. An initial baseline energy model (DOE2 Quest) permitted the team to understand peak cooling loads and iteratively test basic façade concepts. Ultimately, an overall peak hourly cooling load of 12.5 btu/square foot (SF) was targeted as a level that natural ventilation could remove heat from the space without requiring so much airflow as to be disruptive to the work environment. Two key strategies were identified to reduce the baseline peak cooling loads from 26.7 Kbtu/SF/hr to the target: reducing peak solar insolation through optimized façade shading, and reducing electric lights through daylighting. With the employment of a single-zone bulk airflow equation, this target peak load also provided rough sizing of the stack chimneys (44 SF of cross-sectional area on the upper floor, the worst-case scenario since the shorter vertical distance provides less draw).

Solar studies and daylighting

Figure 2 - Peak load target reductions and associated solar shading strategy. Image courtesy of ZGF Architects LLP.

Figure 2 - Peak load target reductions and associated solar shading strategy. Image courtesy of ZGF Architects LLP.The architecture team explored numerous design alternatives to reduce peak solar loading by over 80%. Ultimately, three strategies were adopted that resulted in a combined 81.1% reduction: decreasing the glazed area of the façade by 40.8%, selecting better-performing glazing that reduced insolation by 34.1%, and integrating external horizontal shades that reduced insolation by 51.6% during peak late morning hours (see Figure 2).

At the same time, iterative daylight studies quantified expected savings from the reduction of daylight use. An early baseline digital model (using radiance) was calibrated with a physical daylight model tested at the UW’s BetterBricks Integrated Design Laboratory; the digital model could then be quickly adapted to test the effect on daylighting from various façade configurations. It was found that the selected façade configuration reduced electric lighting use during peak summer morning hours by 67%, if a high-performance daylight redirecting blind was employed to eliminate glare while redirecting daylight to the ceiling. The blind had the additional benefit of permitting airflow into the office (compared to a fabric shade).

Ventilation and laboratory safety and cooling

Operable exterior windows were developed to achieve the required aperture area for adequate airflow. Two sets of awning windows were included. The upper windows were sized to provide the required airflow and opened by mechanized actuators to provide controlled airflow as necessary. The lower windows provided equal area, but were designed to be opened and controlled by occupants as needed.

Figure 3 - Sectional CFD test of worst-case infiltration situation. Image courtesy of Affiliated Engineers, Inc. (Seattle, WA).

Figure 3 - Sectional CFD test of worst-case infiltration situation. Image courtesy of Affiliated Engineers, Inc. (Seattle, WA).In order to ensure that the natural ventilation scheme would not compromise researcher safety, computational fluid dynamic (CFD) models (originally built to validate reducing the required laboratory air changes from the university standard of 10 to a more optimized value of 6) were adapted to test the effect of office airflow on laboratory ventilation. Among many probable variations, a key worst-case configuration was tested that included a 35-mph wind blowing directly into the laboratory façade, infiltration simulated by a 1-in. crack running the entire length of the laboratory wall, and a laboratory door that was propped open against established procedures. In this case (and all others), no pollutants were found to be leaving the laboratory environment, nor was laboratory exhaust compromised (see Figure 3).

Engineering

By the end of design development, it was confirmed that the amount of stack area that could be dedicated per floor was only about 75% of that required to provide completely passive air movement during peak load conditions. For that reason, and to provide greater assurance of the system’s viability, additional cooling features were identified and developed within the office environment, and air movement assists were designed into the chimney stacks. A night ventilation control scheme was developed to provide night cooling of exposed thermal mass when temperatures in the past 24 hr exceeded set thresholds (78 °F interior, or 72 °F exterior). In the office, concrete mass was left exposed in circulation areas, structural columns, and beyond a hanging acoustic ceiling cloud. In addition, a bio-based phase change material was integrated into the ceiling cloud as well as behind walls in private offices. Ceiling fans supply additional air movement during still conditions, providing additional human cooling through increased evapotranspiration during occupied hours, as well as increased air movement during night ventilation. Finally, two sources of additional cooling were recognized by virtue of the laboratory conditioning and ventilation requirements. The glass wall separating the office would effectively function as “thermal mass” since the laboratory air would be conditioned to approximately 72 °F at all times. Secondly, in order to ensure consistent negative pressure in the laboratory, 500 cubic feet per minute (cfm) of its (conditioned) makeup air was supplied on the office side of the partition, also providing bonus cooling to the office.

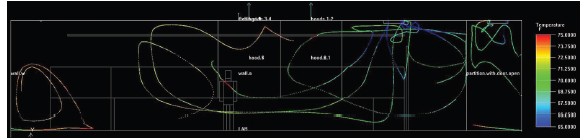

Figure 4 - Three-dimensional section showing airflow pathway from windows through stack turbine ventilators. Image courtesy of ZGF Architects LLP.

Figure 4 - Three-dimensional section showing airflow pathway from windows through stack turbine ventilators. Image courtesy of ZGF Architects LLP.Chimney exhaust stacks incorporate several elements to ensure adequate airflow. Turbine ventilators induce air exhaust with wind from any direction, and additional operable louvers and an electric motor backup in the turbines ensure airflow in all conditions. In addition, a glazed panel was incorporated in the west–southwest orientation of the stack, inducing a solar assist to airflow by increasing the buoyancy of exhaust air during peak summer months (see Figure 4).

Cost analysis

Cost analysis showed that additional expenses and savings associated with natural ventilation resulted in a minor overall increase of $130,000 to the project cost after accounting for reductions in the building cooling and ventilation system. The analysis also showed that in-slab radiant floor heating (with integrated insulation) provided the most cost-effective heating system in conjunction with natural ventilation. Thermal models showed that this scheme would provide occupant comfort in the office for over 97% of operating hours, and should save an estimated 68,000 annual kilowatt-hours over a mechanical conditioning baseline case.

Conclusion

Providing natural ventilation in a technical environment is not easy, and requires a dedicated team and integrated design. In addition, natural ventilation is possible in the Pacific Northwest climate, and presents a significant overall campus strategy for the University of Washington’s climate neutrality plan to reestablish the precedent of not using mechanical cooling in faculty and staff offices. At the same time, it must be recognized that given the energy intensity of the research environment, natural ventilation represents a minor portion of the overall building’s energy efficiency. In addition, as a building targeting Leadership in Energy and Environmental Design (LEED) Gold certification, it must also be recognized that natural ventilation is not necessarily encouraged by the LEED system and the ASHRAE 90.1 energy modeling guidelines. Ultimately, the reasons to pursue this strategy entail creating quality, comfortable environments, and the potential energy savings in pursuing natural ventilation on a larger basis through the built environment.

Mr. Flint Chatto is Associate AIA, LEED® AP, ZGF Architects LLP, 925 Fourth Ave., Ste. 2400, Seattle, WA 98104, U.S.A.; tel.: 206-623-9414; fax: 206-623-7868; e-mail: [email protected].