In the world of laboratories, the discerning eye of an

efficiency expert must wince while witnessing sample preparation. Nowhere else in the laboratory is

there such an erratic work flow.

Laboratorians measure, heat, mix, centrifuge, and extract fragile biological samples in preparation for

accurate analyses. Incessant deadlines attempt to

maximize output, but the batching protocol for

plasma and serum samples fractures any illusion of

automation.

Over 330,000 specimens are processed per year by a

typical hospital or independent laboratory,1 with 85%

requiring some form of preanalytical preparation.2

Current methods require a medical technician to

make more than 60 decisions while preparing a sample.

The extrapolated conclusion here is that sample

preparation—in a high-work-flow laboratory—is a

by-product of 16.8 million decision points yearly, at

zero tolerance for error.

Laboratories today are investing in large, complex

laboratory automation systems that emulate manual

techniques. Much of this technology does not appear

to improve or streamline the sample preparation

process. If we are serious about laboratory automation,

we must dissect the process of sample preparation,

locate the inherent flaws, fixate on delays, and

reinvent the technology until the word “efficiency”

can be honestly reapplied to the entire laboratory.3

Centrifugation as a sample preparation technology

There is no better place to begin our critical examination

of sample preparation than to look at centrifugation.

Centrifugation is, by far, the most common form of plasma and serum separation

(70–80% of blood specimens are centrifuged).4 The technology’s primary drawbacks

are the subjugation of living organic

matter to 10–15 min of immense pressure—amounting to 1000–5000 g forces—and the

delays.

Why, then, should we be surprised that after

a resultant sample is analyzed, measured,

and interpreted, the analysis must be

rejected? After all, we have created the

harshest of conditions for cells, large proteins,

and molecules. Therefore, it should

not shock us that some results of subsequent

analyses mandate reprocessing.

Present-day methods require large ancillary

equipment investments for already shrinking

floor space, and entail additional

planning to calculate loading times,

spin-up times, spin-down times, and

unloading times. In addition, centrifuging

exacerbates batching, further delaying the

entire process.5

Microfiltration: a reliable, alternative technology

Is there a logical alternative to centrifugation?

Microfiltration gently separates living cells,

thereby ensuring the integrity of the specimen and, more

importantly, completely eliminating centrifugation.

Through specially constructed disposable filter cells

approximating the length of a baby’s finger, microfiltration

has evolved beyond an original

concept of cross-flow and/or tangential-flow

filtration.6,7

Basic microfiltration system

The fundamental microfiltration system from

Bio/Data Corporation (Horsham, PA) comprises

three primary components: 1) disposable

filter cell, 2) filtration module whose

design is determined by the back-end application,

and 3) proprietary software that manages

and controls the microfiltration process.

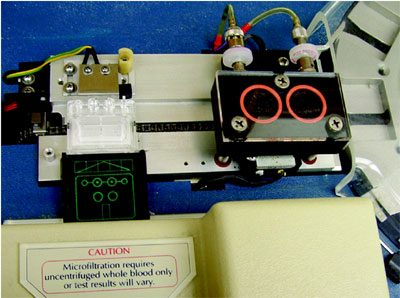

The filtration module processes the filter cell

(Figure 1). The filter cell’s patented architecture

highlights the intricate realities of

microfluidics therein. A whole-blood specimen

is precisely manipulated between two

reservoirs over a microporous membrane and

then along a specially designed, smoothly

sculpted flow channel.

Figure 1 - A filter cell (left) awaits injection of a specimen before cellular

and fibrin solids are removed from the processed plasma (or serum) in

the filtration station (right) during microfiltration. This image was photographed

inside the Microsample Coagulation Analyzer™ model MCA-210 (Bio/Data).

A back-and-forth motion continually cleans the

membrane pores. Optical sensors control the sample

movement until virtually cell-free plasma is determined

to be present. All the preanalytical variables

are radically reduced, as 400 μL of plasma for analytical

testing is produced from 2 mL of whole blood in

45 sec. The software ensures precision in the amount

of the deliverable sample.

Technicians’ involvement is minimized, as is their

exposure to blood-borne pathogens. The laboratory

manager now observes a single operation in which the

plasma or serum is extracted. In addition, the primary

sample tube is never uncapped. (Microfiltration also

eliminates the sample pumps and rinse fluids required

in most analyzers.)

The filter cell

A plastic, disposable microfiltration filter cell comprises

three or four elements:

- Reservoir, to contain the sample—The reservoir consists of two

equal-volume chambers that, when assembled with the base, are connected

via a horizontal flow channel.

- Microporous membrane, 0.6 μm pore size, positioned between the reservoir and base with a flow channel above and a collection grid below.

- Base, which collects and delivers the filtrate for processing or testing.

- Cover sheet attached below the collection area to the bottom of the base (optional, dependent upon design).

Filter cells are intended to reside in an analyzer,

whose design varies by analysis type, e.g., optical

(density, color, or fluorescence), electrical (conductance

or impedance), or mechanical (magnetic bead

or bar). Design also depends upon whether test

reagents are introduced into the filter cell.

System operation

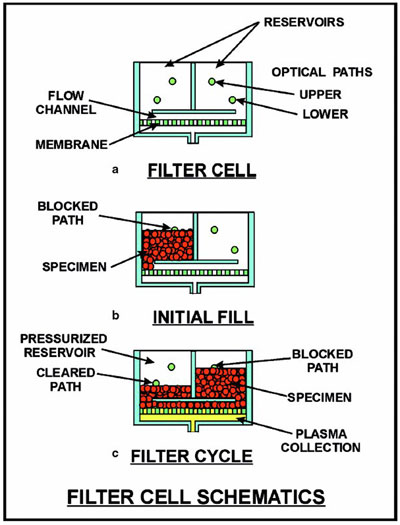

Two optical paths in each of the filter cell’s two reservoir

sections are continuously monitored by detection

circuitry arrays in the filtration module. The

two paths correspond to the lower and upper levels

of each reservoir, and the results from the optical

arrays engage and disengage the system’s variable filtration

motion, and determine when the proper volume

of plasma or serum is achieved (Figure 2a).

Figure 2 - Schematics depict how the optics from a filtration module guide

the back-and-forth movement of a specimen across a microporous membrane:

a) basic filter cell, b) introduction of a specimen into the cell, and c) operation

during microfiltration.

When both optical paths are clear, no blood is present.

If the paths in one reservoir are blocked, a fluid

is in the chamber. A filter cell is moved into position

to initiate operation, and the optical system checks

to confirm two paths in one reservoir chamber are

blocked and two paths in the other chamber are

clear (Figure 2b).

A pneumatic system gently pressurizes the side of the

reservoir whose upper path is shown to be blocked. The

pressure eases the blood down a passageway in the bottom

of the filled reservoir chamber into the flow channel,

across the microporous membrane, and up through

a passageway in the bottom of the empty chamber.

The pressure differential causes plasma to pass

through the membrane, as cells flow across the membrane

surface. The pressure continues to be applied until the lower optical path indicates the chamber is

clear, at which time the pressure is relieved.

The system then checks the opposite chamber to

ensure its lower path is blocked. Once confirmed,

pneumatic pressure is applied to that reservoir until

optics confirm its lower path has cleared. Thus, an

alternating forward-reverse flow ensues. Once the

optical sensors indicate a predetermined sample volume

has been produced, the plasma or serum is

promptly removed for analysis (Figure 2c).8

Plasma quality

The indiscernible attributes of native plasma are

maintained in microfiltration, because the separation

method is less traumatic to the cellular matter

in blood. The filtration pressure—about 129 mm of

mercury—is comparable to normal blood pressures of

120–140 mm of mercury. Cells are not subject to

extreme forces or pressures and do not excrete activating

materials into the plasma.

The effectiveness of plasma extraction may be gauged

upon how many residual platelets—the smallest cells

in blood—reside in the sample. For an example of

microfiltration’s effectiveness, blood was drawn from

three people and each specimen was placed into a

sodium citrate anticoagulant. The specimens were then

apportioned into batches of 20 and 16 for processing by

microfiltration and centrifugation, respectively.

The 20 specimen tubes were processed sequentially

for 30 sec each, utilizing the MCA-310 microfiltration coagulation analyzer (Bio/Data) with the filter

cells. The other 16 specimens were collectively spun

using a centrifuge at 2500 × g for 15 min.9

Platelet counts in the centrifuged samples ranged

from 4490 to 8000, well within the Clinical Laboratory Standards Institute’s tolerance of 10,000 platelets per cubic millimeter in “platelet-poor

plasma.”9 By comparison, microfiltration-prepared

samples were so low in platelets that final results had

to be determined manually. The samples studied contained

fewer than 200 platelets per cubic millimeter,

0.5% of centrifugation’s allowance (Table 1);10 thus,

samples processed by this technology can be

described as “virtually platelet-free plasma.”

Summary

Clinical managers are constantly evaluating, reviewing,

and reevaluating how their protocols expedite or

slow down the work flow. The constant emphasis on

better methods of sample preparation is a self-admission

of the challenges faced by laboratories utilizing

centrifugation. Microfiltration rapidly separates

plasma or serum from whole blood and easily integrates

into automated configurations to complement

standard laboratory testing.

The advantages of microfiltration are:

- Simplification of the sample preparation process, enhancing automation.

- Elimination of centrifugation.

- Major reduction of time required to obtain plasma or serum.

- Elimination of interferences from cellular materials.

- Suitability of samples for all existing test methods.

References

- Wolman, D.M.; Kalfoglou, A.L.; LeRoy, L. Medicare Laboratory Payment Policy: Now and in the Future. National Academy Press: Washington, DC, 2000; Table 2.1.

- Zakowski, J.; Powell, D. The future of automation in clinical laboratories. IVD Technol. Jul 1999, 5(4), 48–57.

- Valenstein, P.; Souers, R.; Wilkinson, D.S. Staffing benchmarks for clinical laboratories. Arch. Pathol. Lab. Med. Apr 2005, 467–73.

- Holman, J.W.; Mifflin, T.E.; Felder, R.A.; Demers,

L.M. Evaluation of an automated preanalytical robotic workstation at two academic health centers. Clin. Chem.2002, 48(3), 540–8. - Pfister, M. Laboratory automation—industry transformation or dead end. HBS Quarterly (London), Mar 2004, 7–9.

- Van Reis, R.; Zydney, A. Membrane separations in biotechnology. Curr. Opin. Biotechnol.2001, 12, 208–11.

- Murkes, J.; Carlsson, C.G. Crossflow Filtration Theory and Practice. John Wiley & Sons, New York, NY, 1988.

- Coville, W.E.; Trolio, W.M. Preanalytical specimen preparation. J. Assoc. Lab. Automat. Mar 2000, 5(1), 72–80.

- Procedures for the Handling and Processing of Blood Specimens; Approved Guideline, 2nd ed. Clinical Laboratory Standards Institute (CLSI, formerly National Committee for Clinical Laboratory Standards), H18-A2, Oct 1999, 19(21).

- Laurich, M. Microfiltration Platelet Counts. Product Development Study Report, Bio/Data, Mar 1998.

Mr. Coville is Manager of Product Development, and Mr.

Loika is Corporate Communications Manager, Bio/Data

Corporation, 155 Gibraltar Rd., Horsham, PA 19044-0347,

U.S.A.; tel.: 215-441-4000; fax: 215-443-8820; e-mail: [email protected].