Nuclear magnetic resonance (NMR) spectroscopy is a

powerful analytical technique

that is commonly used to provide

structural information as

well as other chemical metrics

such as sample composition

and highly involved

reaction kinetics. While

NMR is a very informative

tool, its sensitivity is orders of

magnitude lower than other

analytical detection techniques

(e.g., mass spectrometry or UV detection). A number

of approaches have been

developed to improve the

signal-to-noise ratio of an

NMR measurement (i.e.,

high-strength magnets and

cryogenically cooled probes).

These approaches do improve

the S/N, but they also lead to

a significant increase in

instrument cost. An alternative

way to enhance the sensitivity

is to increase the sample

size, but this is not an

acceptable approach for many

studies due to the difficulty of

obtaining the sample (especially

for molecules of biological interest).

In recent years, the use of microcoil

technology has dramatically

improved the sensitivity of NMR

measurements at a considerably lower

cost than cryogenic probes.1

Delivery of the sample to the microcoil

probe is an important issue that

is closely related to the improvement

in sensitivity, since both factors must

be optimized to maximize the

throughput of the system and its utility

to the analyst. In many facilities, a

high-throughput autosampler is

employed, while chromatographic or electrophoretic methods of separation

are used in other facilities. A

seamless analytical method is desired

to optimize the throughput of the

analytical laboratory.

This paper describes the use of microcoil

technology to improve the sensitivity of

NMR measurements. It discusses a

number of sample handling approaches

ranging from microflow injection to

solid-phase extraction (SPE), HPLC,

and electrophoretic migration.

Use of a microcoil to optimize

the sensitivity of an NMR spectrometer for analysis

of microgram and submicrogram

mass levels

In general, the radio frequency (RF)

receiver coil should closely conform to

the sample to ensure good detection

sensitivity. A properly designed NMR probe will maximize both the observe

factor, which is the ratio of the

sample volume being observed

by the RF coil to the total sample

volume required for analysis,

and the fill factor, the ratio

of the sample volume being

observed by the RF coil to the

coil volume. Since the sensitivity

of the coil is roughly

inversely proportional to the

coil size, a probe that employs

a 1-mm RF coil has a mass sensitivity

that is roughly tenfold

greater than a conventional

tube probe that utilizes RF

coils closer to 10 mm in size.

Due to their small size and

patented approach to magnetic

susceptibility matching,

CapNMR™ microcoil probes

(Protasis, Inc., Marlboro,

MA) are easy to use and shim

and typically require only a

handful of the available system

shims to meet resolution specifications.

A detailed discussion

of microcoil NMR design is

presented in Ref. 1.

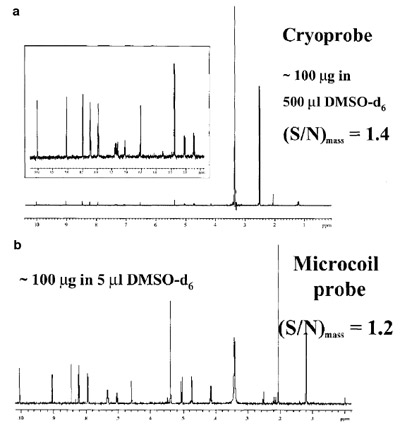

Figure 1 - NMR analysis by cryoprobe and microcoil probe. a) Single

scan using a cryoprobe. The S/N was normalized over the sample

quantity in the active volume (230 μL, Vmrm = 1.5 μL). b) Scan using a

microcoil probe. Reproduced with permission from Dr. Feng Xu, Bristol-Myers Squibb Research Institute (Wallingford, CT).

An example of the utility of

a microprobe is shown in

Figure 1, in which the spectrum of an

unknown is presented using a CapNMR probe and a cryoprobe. While

the S/N for the two spectra are similar,

it is important to note that the

spectrum obtained from the CapNMR probe had considerably less

background signal effects due to the

100-fold reduction in solvent volume

for the mass detected.

Use of a microcoil to obtain

NMR data from biomolecules

The use of a microcoil may be advantageous

for the collection of NMR

spectra of biomolecules since obtaining

a sufficiently large quantity of a

protein (or other large molecule)

may be exceedingly difficult or tedious. In a recent study, Peti et al.2

used the TXI HCN z-grad CapNMR

probe to determine protein folding,

as well as for complete sequence-specific

backbone assignment of a 10-kD protein (TM0979 from Thermotoga

maritima). The probe is well

suited for obtaining the NMR spectrum

of protein samples produced in

nonoptimized, highly automated protein

expression pipelines (where the

amounts of protein produced routinely

have not been sufficient for

traditional 5-mm tube NMR investigations).

The probe opens up a new

avenue for protein folding screening

in the context of structural proteomic

projects.

Peti and coworkers have demonstrated

sequence-specific backbone

assignment using heteronuclear

triple resonance HNCA and

HNCOCA experiments on the CapNMR probe. The group has also

demonstrated TOCSY transfer

between the aliphatic region and

the aromatic region for the first time

in an HCCH–TOCSY experiment

for purposes of side-chain assignments.

This measurement was possible

because of the low power

requirement of the CapNMR probe;

it is a direct result of the mass sensitivity

of the probe and is precluded

in many larger probes due to RF

power restrictions.

High throughput is an

increasingly critical consideration

in many laboratories

in which a large

number of samples are

delivered to the NMR

probe via an autosampler.

The overall time per sample

is a critical issue and is

determined by the residence

time of the sample

in the probe and the sample

preparation and delivery

steps. When the

microcoil probe is

employed, the sensitivity

of the measurement is

increased; thus, the residence

time for data acquisition

can be reduced. Additional

time can be shaved off the time per

sample by optimizing each of the

additional steps in the sample preparation

and transfer process.

One of the most widely used NMR

automation systems employed in

NMR flow injection systems is the model 215 liquid handler (Gilson, Middleton, WI). Protasis and MRM

(Savoy, IL) have developed a means

of loading samples into the CapNMR probe using this liquid handler

in conjunction with a high pressure, HPLC-grade pump. This

has convinced a number of major

pharmaceutical companies to adapt

their flow NMR system to the CapNMR probe.

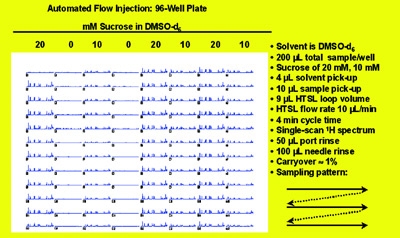

Figure 2 - Automated flow injection for capillary NMR. Reproduced with permission

from Dr. Timothy Peck, Protasis/MRM Corp.

Scientists at GlaxoSmithKline

(Research Triangle Park, NC) have

advanced this development by implementing

a filter maintenance protocol

that provides for significantly increased

mean time to failure. They have

reported error-free injection of thousands

of samples without filter change.

The Inova 600-MHz NMR spectrometer based system (Varian, Palo Alto, CA)

that was used in this study included a

specialized needle (Gilson), custom

loading port (Protasis/MRM), filter,

and CapNMR probe. Figure 2 shows a

collection of spectra from a 96-well

plate. This capillary flow automation

system requires considerably less sample

and solvent and provides less system

downtime and smaller solvent residual

peaks.

The Open Access Automation NMR

system (Protasis/MRM) comprises a

user interface to control the CTC

autosampler (Leap Technologies,

Carrboro, NC) with the NMR. It can

be used with all commercial spectrometers and provides an operator-centric

view of the system for sample control,

report management, and accounting

information. The liquid handler is

specifically designed for microliter volume

samples.