The previous article (American Laboratory, Apr 2011)

ended with an unsolved problem: how to implement

a pass-fail method if the blank matrix contains a non-negligible

amount of the analyte. This installment will

address the above situation.

The best way to proceed would be to locate a simulated or synthetic

matrix that is as similar as possible to the material at

hand. Then the analyst would have the “true blank” needed for

applying the above protocol. An example would be drinking-water. Calibration and recovery curves for ionic environmental

contaminants could be studied by preparing (in, e.g., deionized

or reagent-grade water) a solution containing typical drinking water

levels of chloride, carbonate, nitrate, and sulfate. Such

a simulation would not, by construction, contain any of the

analyte(s) of interest.

Another route would be to use a “recipe” adopted by a consensus-based

organization. The D19 Water Committee of ASTM International

(formerly known as American Society for Testing and Materials)

has developed both substitute ocean water and substitute

waste water. Such matrices may provide an acceptable substitute

for some methods.

If a simulated matrix is not feasible for whatever reason, then the

approach is more involved and using regression is almost inevitable.

A suggested path is the following and assumes that the blank

level is thought to be roughly at or below the spec level. The first goal

is obtaining as reliable an estimate as possible of the amount of analyte

in the blank.

Step 1—Estimate blank’s level via a calibration curve

A calibration curve (in pure solvent) (see earlier installments of

this column for details on calibration) should be obtained in the

concentration range of interest. This plot can then be used to

calculate a rough estimate of the blank’s analyte concentration.

(The qualifier of “rough” is used because no information is available

about the analyte’s recovery in matrix.)

Step 2—Conduct a spiking study to assess recovery

To check the rough estimate (and get a handle on recovery),

a spiking study (in the matrix) should be conducted, where

the top concentration is at least twice the rough estimate. A

minimum of three concentrations should be chosen between

the rough estimate and the doubled amount. If possible, each

concentration should be analyzed five times. A recovery curve

(see Parts 20 and 21, American Laboratory, Feb 2006 and Apr

2006, respectively, for a discussion of recovery curves) then can

be generated from the pure-solvent calibration curve (assuming

the concentration range is similar to that in the spiking work).

If the recovery is “close” to 100%, then the rough estimate probably

is a reasonable one.

Especially if the recovery is “well away” from 100%, the blank’s estimate

can be checked by comparing the response for the blank itself

with the response from the “twice-the-estimate” spike. If the higher

number is ca. twice the lower, then the estimate is probably reasonable.

Step 3—Utilize standard addition as a final check

If all is “OK” so far, then standard addition could be employed

as a final check on the blank’s estimate. (As has been mentioned

previously, standard addition, though often used as the only

alternative, has statistical drawbacks; for details, see American

Laboratory, Part 21.)

If the recovery curve: 1) is linear, 2) has a prediction interval with

an acceptable half-width, and 3) has an acceptable recovery (as

measured by the slope of the line), then it is reasonable to estimate

the blank’s level via the standard-addition approach. If this estimate

“matches” previous ones, then a “warm, fuzzy feeling” is probably

in order.

To apply the above protocol, an example will be shown where

there is no analyte in the blank matrix. Thus, the analyst can

“contaminate” the blank at a known level, thereby providing a

solid reference point for critiquing data. For this exercise, consider

a subset of the fluoride data that were discussed in Parts 20

and 21 of this series. No fluoride was found in the matrix blank,

so the lowest spike level of 10 ppb contained only that concentration.

To illustrate the above steps, the 10-ppb spike will be

considered to be the blank; concentrations of subsequent levels

will be the amount each level is above the 10-ppb “blank.”

Step 1—Calibration curve

The calibration curve (in deionized water) was based on 5–8

replicates of each of 12 standards, ranging from 1.5 to 47 ppb;

a blank (which gave no integratable response) was also tested.

The data indicated that weighted least squares was the appropriate

fitting technique; a straight line was adequate as the

model. This curve was used to evaluate the “blank” matrix.

The mean concentration (from eight replicates) was estimated

to be ~8 ppb.

Step 2— Spiking study

Five spike levels (above the “blank”) in matrix were prepared,

ranging from 2.5 to 15 ppb. Each solution was analyzed eight

times. Recovered concentrations were calculated using the calibration

curve from Step 1 and a recovery curve was constructed.

Ordinary-least-squares (OLS) was found to be the appropriate

fitting technique. A straight line showed some lack of fit

(p-value = 0.409), but a quadratic curve overfitted the data;

thus, a straight line was selected. The equation for the resulting

line was:

predicted ppb = 7.9 + (0.88 * true ppb)

The proportional recovery (0.88) was not as high as one would like,

but acceptable. The offset of 7.9 ppb was as expected, given the results in Step 1. At 95% confidence, the half-width of the prediction

interval was ca. 1 to 2 ppb.

Step 3—Standard addition

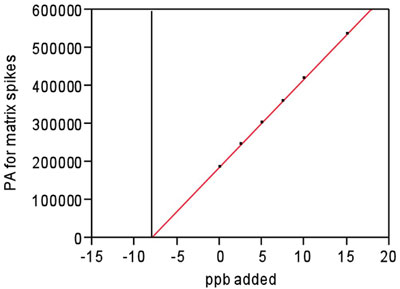

Figure 1 - For the matrix spikes, plot of response versus the added concentration.

Black vertical line shows the determination of blank’s level (8.06 ppb) via

standard addition. PA = peak area.

The above work showed that the three conditions for proceeding

with Step 3 were met. For the standard-addition procedure, the

responses (peak areas) obtained for each matrix spike (including

the “blank”) were plotted versus the spike concentration. A

straight line with OLS fitting was appropriate; thus, it was reasonable

to proceed with the standard-addition calculation. Extrapolation

of the line showed that ppb ≈ –8.1 when PA = 0 (see Figure 1).

In this illustration, the results from the various steps supported each

other and it was reasonable to assume that the “blank” contained

~8 ppb of fluoride, plus-or-minus ~1 to 2 ppb. Not bad agreement

with the known value of 10 ppb!