Valve switching applications are becoming popular in ion chromatography (IC). Example applications include matrix

diversion or matrix elimination prior to analysis of trace components.

A conventional ion chromatography system is usually

equipped with a single injection valve, and installing additional

valves for various applications such as two-dimensional

(2-D) separations and sample preparation applications is cumbersome.

The instrument detailed here has an integrated

automation management module supporting various valve

configurations and a reaction coil heater for postcolumn reaction

applications. Here, the authors will discuss the utility of

the system for various valve switching applications.

First, the instrumentation details of the system and the

automation module will be discussed. Next examples of

applications will be shown, including 2-D analyses of perchlorate

in high-ionic-strength matrices and a matrix neutralization

approach showing analysis of trace anions in concentrated

base. With the 2-D analysis method in

conjunction with suppressed conductivity detection, it is

possible to detect low levels of perchlorate without the use of

an expensive mass spectrometer.

System description

Figure 1 - The automation manager (AM) in the ICS-3000 detector/chromatography compartment (DC) is highlighted above. Mounted

as a sliding tray for easy plumbing, the AM is versatile enough to handle

difficult applications by supporting a variety of valve configurations.

The ICS-3000 Reagent-Free™ IC (RFIC™) system (Dionex Corp., Sunnyvale, CA) combines traditional

instrument improvements for signal enhancement with

valving and control for easy implementation of complex

applications. The system consists of a pump (single or dual,

SP or DP, respectively), eluent generator (EG), detector/chromatography compartment (DC), automation

manager (AM), autosampler (AS), and tablet PC. The system

can be configured as a single or dual system and incorporates

the latest advancements in RFIC system technology

(Figure 1). When configured as a single system, the additional

pump from the DP can be used for miscellaneous

applications such as pumping a deionized (DI) water stream

for sample preparation applications.

From ordinary DI water, RFIC systems generate high-purity

eluents that perform superior separations, and

then neutralize the eluent back to DI water in the suppression

step to facilitate sensitive detection using a conductivity detector. Using the EG with the continuously

regenerated-trap column (CR-TC) minimizes baseline

shift during the run, when pursuing eluent concentration

step changes or gradients.

The DC compartment consists of three sections for separation,

detection, and automation. The separator columns are

housed in the DC in a controlled thermal environment.

Capable of single or dual analysis, the DC houses conductivity

and electrochemical detectors. Two detector cells are

available for “plug-and-play” conductivity and electrochemical

operation. The DC also contains two valves in the

lower compartment for injection and sample preparation applications. All valves are on slide-out trays for easy installation and troubleshooting. An important feature within

the DC is the AM, a slide-out tray that is configurable with

up to two high-pressure valves, two low-pressure valves, and

a postcolumn reaction heater. The AM facilitates valve

switching applications.

The AM is mounted inside the DC compartment so that

sample preparation steps such as preconcentration and

matrix removal are in the near vicinity of the separator

columns. In conventional IC systems, mounting the sample

preparation valves close to the separator column is difficult

and often leads to excessive band dispersion. Due to the

close proximity of the AM to the separator columns, band

dispersion issues are minimized.

Two-dimensional perchlorate analysis

Although there are no federal drinking water regulations

for perchlorate, various states have adopted their own

advisory levels that range from 1 to 18 ppb. Trace-level

analysis in IC is typically done using concentrator

columns or large- volume injections. When high levels of

matrix ions are present, large-volume injections are preferred

over concentration methods since the matrix ions

can elute off the analyte of interest from the concentrator

column. It should be noted that large-volume injections

not only enhance the sensitivity of trace components, but

also enhance the sensitivity of matrix components. In

some cases, the matrix components interfere with the

analysis by coeluting or eluting the trace component into

a broad peak, leading to poor detection. This is the case

with perchlorate analysis.

Perchlorate in drinking water is typically analyzed in the ppb

range, whereas the matrix concentrations are at the hundreds-of-ppm level. U.S. EPA Method 314.0 was a direct injection

method but required an off-line matrix elimination step with

solid-phase extraction cartridges for samples containing high

levels of matrix ions. U.S. EPA Method 314.1 was published

as an update and allowed improved detection of perchlorate

in high-ionic-strength matrices. Alternatively, an automated

2-D heart-cutting method can be used as an in-line approach.

The ICS-3000 system was configured as a two-channel dual

system for this application. The injection valve in the first

dimension was fitted with a large-volume sample loop (4

mL). The injection valve in the second dimension was fitted

with a concentrator column that focused the heart-cut analyte

peak from the first dimension for further analysis in the

second dimension.

Figure 2 - Diagram highlighting components and configuration for

2-D IC in the ICS-3000.

The schematic for matrix removal and signal enhancement

is shown in Figure 2. There are several advantages of the 2-

D matrix diversion approach. Initial sample loading onto

the 4-mm column allows a large sample injection volume

(large amount of sample) due to the high capacity of the

analytical column and higher selectivity for perchlorate

relative to the matrix ions. Second, it is possible to focus

the perchlorate peak that is partially resolved in the first

dimension onto a concentrator column in the second

dimension. The suppressed effluent with hydroxide eluent

is water, which provides the ideal environment for ion-exchange

retention and focusing. Third, the second

dimension is operated at a lower flow rate relative to the

first dimension, thereby enhancing the detection sensitivity.

Finally, this approach also allows the potential to combine

two different chemistries in two dimensions, thereby

enabling a selectivity not possible using only a single

chemistry dimension.

Figure 3 - Chromatograms of a 1-D (a) and 2-D (b) analysis of perchlorate

in a high-salt matrix. Note that perchlorate is not detected due to

interference from the matrix ions in the 1-D separation. In the 2-D separation,

the interfering matrix has been removed and the perchlorate peak

is enhanced and also quantifiable.

Figure 3a shows the analysis of a sample in the first dimension

consisting of 5 ppb perchlorate in the presence of 1000

ppm matrix ions. As can be seen in this figure, the matrix

interferes with the detection of the perchlorate peak,

which is broadened and difficult to quantify. This same

sample was analyzed using the 2-D approach by using the 2-mm column in a second dimension. As shown in Figure 3b,

perchlorate is well resolved and free from any matrix

effects. Chromatography with matrix diversion and concentration

followed by analysis on a 2-mm column and a

concentration-sensitive detector yields sensitivity proportional

to the flow rate ratio of the first dimension versus

the second dimension: a fourfold gain. Due to the physical

proximity of the two dimensions in the system and minimal

delay volume, it was possible to achieve excellent peak

shape and recovery.

AutoNeutralization

Another example of valve switching involves a technique

known as AutoNeutralization™ (Dionex Corp.). This technique

is used when it is necessary to quantify anionic contaminants

in concentrated bases. The strategy most often

employed is to dilute the sample. This dilution reduces the

concentration of the interfering matrix ion to a level that

does not affect separation. However, dilution also reduces the

concentration of trace anions, compromising their detection.

AutoNeutralization solves the analytical problem of achieving

good detection limits of trace anions in concentrated

bases by neutralizing the base using a membrane-based neutralizer

device. The sample anions are in a water background

after neutralization and can be focused back onto a

concentrator column that is located on a third valve in the

lower compartment.

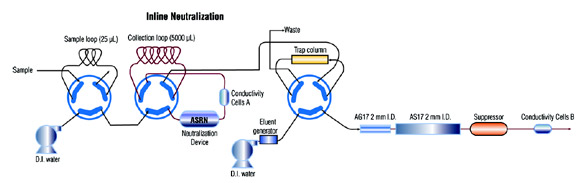

In this setup, the system was used in conjunction with an

AM module.

Two six-port valves on the AM module were used for neutralization.

The first valve was used for loading the sample onto

an ASRN™ neutralizer device (Dionex Corp.). The second

valve was used for holding the sample in the collection loop

and rerouting the sample back through the neutralizer and

diverting the neutralized stream onto a concentrator column.

Figure 4 - Plumbing configuration required for AutoNeutralization applications.

This plumbing configuration is shown schematically in

Figure 4. In the AutoNeutralization process, the concentrated

base sample is loaded into the 25-μL sample loop of

the sample valve. The sample loop is switched in-line and

flushed with a stream of deionized water (also known as the

carrier solution). The carrier solution transfers the concentrated

base from the sample loop to the ASRN, where the

sample is partially neutralized, then transferred to the 5000-μL loop. The recycle valve is then actuated to pass the sample

through the ASRN again so that it is completely neutralized.

The completely neutralized sample is finally delivered

to a concentrator column; since the anions are now in water,

they are concentrated as a tight band.

Finally, the anions are eluted from the

trap column to the analytical column,

separated, and detected.

Figure 5 - Chromatographic results of anion analysis with (a) and

without (b) AutoNeutralization, from caustic sample matrix.

Figure 5 shows the results of anion analysis

of a concentrated base sample with

(a) and without (b) neutralization.

Without neutralization, the anions are

broadened and show poor sensitivity in

a 1% sodium hydroxide sample matrix.

In the 50% sample matrix the presence

of the matrix causes a high background that makes detection

of additional anions virtually impossible. Figure 5a shows the

results after neutralization. Note that the large background

has been removed and detection of anions is now possible

with good recovery.

The AM allows easy implementation of the autoneutralization

application without any additional external

valves or controls. The system configuration for this

application was simplified with the AM installed. All

valves, plumbing, trap columns, and ASRN remain

inside the DC compartment, minimizing tubing lengths

and allowing all manipulation of sample to be contained

in a precisely controlled environment. In addition, all

valves are recognized through Chromeleon® control software

(Dionex Corp.), eliminating the use of external

TTL controls or triggers.

Conclusion

The ICS-3000 system provides an effective platform for pursuing

standard and multiple valve switching applications.

Applications have been shown that demonstrate the utility

of the system and the AM module for valve switching applications.

Due to the close proximity of the valves to the

columns and detector cells, this design provides a low-dispersion

platform for implementing multidimensional

sample preparation and analysis schemes. The inherent flexibility

and precise control of the system make such nonroutine

applications easier to implement.

Dr. Jack, Dr. Lin, Mr. De Borba, and Dr. Srinivasan are with Dionex

Corp., 1228 Titan Way, Sunnyvale, CA 94086-4015, U.S.A.; tel.: 408-737-0700; fax: 408-739-4398; e-mail: [email protected]. Dr.

Sekiguchi, Mr. Nakanishi, and Ms. Yoshimura are with Nippon Dionex,

K.K., Osaka, Japan.