Sample introduction has been a problem

for analytical chemists for decades.

In 1984, Richard Browner and Andrew

Boorn went so far as to call sample introduction

“The Achilles’ Heel of Atomic Spectroscopy.”1 Since that time, a multitude

of variations have been developed

and commercialized to address

some of the deficiencies. The most common

form in which samples are introduced

for analytical spectrometry is as

an aerosol via pneumatic nebulization.

The inherent inefficiency of the nebulizer–spray chamber combination has

been investigated by numerous authors,

and Barry Sharp presented a thorough

examination of the problem in two

papers in 1988—one on nebulizers and

a second on spray chambers.2,3 Attempts

to increase the mass-transfer

efficiency

of the sample introduction system

resulted in a wide range of solutions

such as ultrasonic nebulizers (USNs)

and high-efficiency nebulizers.

At typical flow rates, sample introduction

systems based on a nebulizer–spray chamber combination deliver

poor transport efficiencies, typically

between 1 and 3%. The optimum

strategy for improving performance

is to increase analyte transport efficiency.

Ultrasonic nebulizers are said

to improve delivery by an order of

magnitude, and nebulizers that introduce

the aerosol directly into the

plasma approach 100% efficiency,

albeit at greatly reduced flow rates.

Although solid sample introduction

techniques have been reported that

involve laser ablation, direct insertion

devices, powders, or slurries,

these methods appear to have limited

application, since most samples are

prepared in solution.

Inductively coupled plasma-atomic emission spectroscopy (ICP-AES) and ICP-MS are robust and established

techniques for elemental analysis.

These instruments are capable of providing

the required sensitivities, detection

limits, and linear dynamic ranges

for the quantitative determination

of the majority of elements required.

There are exceptions. The elements

of group 14–16 typically exhibit low

sensitivities, due in part to their relatively

high ionization potentials. An

area that continues to receive much

attention is vapor generation. Several

elements of particular concern to both

the environmental and metallurgical

communities are the so-called hydride-forming

elements (As, Sb, Bi, Ge, Sn,

Pb, Se, Te, and Hg). The transformation

of elements into volatile species

has continued to elicit interest from

both the academic community and the

contract laboratory environment.

There are several advantages to introducing

the sample as a volatile species,

and this has prompted Nakahara

to describe it as the ideal method for

sample introduction.4 The principal

advantage is the high transport efficiency

that can be achieved. Le et al.

showed that around 95% of arsenic is

removed from solution when solutions

of arsenic(III) react with borohydride.5

A second advantage is the possibility of

separating the analyte from the matrix.

In order to optimize these advantages,

especially the latter, proper design of the

phase separator is essential. One

major drawback is that the vessel

in which the hydride generation

took place has meant that applications

of the technique were

typically limited to either single-elements

determination, where

the atomic absorption technique

provides excellent results when

combined with a quartz tube

atomizer, or multielement techniques

using the ICP.6,7 Contract

laboratories are normally required

to determine and report on a

large number of elements for the

majority of samples that are analyzed.

This requirement dictates the use of a

multielement technique based on either

atomic emission or mass spectrometry in

order to provide timely results.

The use of vapor generation as a

means of sample introduction for

ICP-AES dates back to the late 1970s.

These early systems used atomic

absorption (AA)-type batch systems

for the generation of the volatile species.

Thompson et al. developed a

continuous system and proposed the

possibility of simultaneous determination

of the hydride-forming elements.

It was also realized that the multielement

capability of the ICP-AES

could further be exploited through the

simultaneous determination of conventional

and hydride-forming elements.

8 Efforts over the last two and a

half decades have provided a number

of designs that seek to combine the

nebulizing function with the vapor-generation

function into one device

in order to determine, simultaneously,

both hydride formers and nonhydride

formers. The first strategy used a dual

tandem nebulizer design.9 A reductant

solution aerosol, generated by the

first nebulizer, was introduced into the

gas orifice of the second nebulizer, to

which the sample solution was fed.

The mixed aerosol was subsequently introduced to the plasma. This

approach, as well as other systems

whereby the hydrides are formed using

a nebulizer or “detuned” nebulizer, are

nonideal, since a significant amount

of reagent is introduced to the plasma.

A second strategy involved collecting

the waste solution from the nebulized

aerosol in a reservoir formed using an

elevated drain inside the spray chamber.10 Here, the reductant solution

was pumped into the reservoir to generate

the hydride species. Hydrogen

gas, which is also formed during the

reaction, served to strip the volatile

species from solution and into the

spray chamber, where they become

entrained in the sample aerosol that

is transferred to the plasma. This basic

approach has been used several times.

Reservoir-based systems have two

primary disadvantages: sample cross-talk

cannot be avoided, and high acid

concentration is required to generate

sufficient hydrogen for adequate

stripping of the analyte. One system

has a dedicated pump channel for the

constant introduction of concentrated

hydrochloric acid to ensure adequate

hydrogen production. This extra

channel allows the sample to be prepared

at lower acid concentration, but

issues remain in regard to the cost of

the additional acid and to the safety

of handling, the consequences of a

highly corrosive environment, and the

disposal of highly acidic wastes.

A third approach was to use a manifold

system to mix the sample and reductant

together in a T, after which the mixture

is introduced into the spray chamber.11 The drawbacks associated with

this approach are described above.

A recurrent problem, and one that

has challenged many researchers over

the last three decades, has been the

rapid removal of the volatile hydrides

(and other species) from solution.

Early designs of the gas–liquid separator

relied on high acid concentrations

to strip the volatile species from solution,

as described above. However,

in a series of papers, Brindle and others

showed that low acid concentrations

resulted in better signals from

hydride-forming elements, but they

relied on a frit-based separator with

argon flowing through it to generate

small bubbles, thereby substituting

argon for the chemically generated

hydrogen to strip the volatile analytes

from solution.12 The importance

of gas–liquid separator design on performance

was further illustrated in

a paper by Brindle and Zheng, who

compared a variety of commercial and

purpose-built gas–liquid

separators

for the determination of mercury by

cold-vapor generation.13 The upshot

was that the two designs that performed

best were small dead-volume

systems, designed for applications to

flow-injection systems.

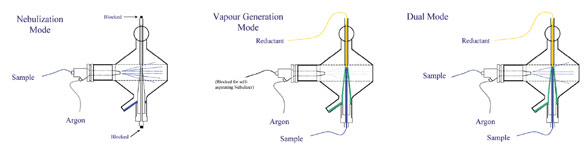

Figure 1 - Multimode Sample Introduction System.

In 2002, McLaughlin and Brindle

published a paper that presented a

radically new design for the combined

nebulizer/gas–liquid separator.14 The Multimode Sample Introduction

System (MSIS) is based on

a cyclonic spray chamber that has

been modified by the addition of

vertically opposed tubes in the center

of the chamber (Figure 1). The

device was patented in May 2005.15

Figure 2 - Modes of operation.

The system is capable of operating

as a conventional spray chamber,

as a gas–liquid separator, or

as both simultaneously. The various

modes of operation are shown

in Figure 2. The MSIS is unique in

its approach to vapor generation in

that it employs nonconfined point

gap mixing of the sample and reductant,

and effective stripping of the

volatile species using thin flowing

film technology. The mixed solution

in this case flows down a conical

ground glass tube to the drain, where

it is continuously pumped to waste.

Gas from the nebulizer strips the

volatile species and delivers them to

the plasma. The sample flow can be

split, delivering part of the solution

for nebulization and the remainder

for hydride generation. These

characteristics virtually eliminate

the possibility of sample cross-talk

that is inherent with reservoir-based

designs discussed above. The MSIS

essentially eliminates signal noise

caused by sputtering that occurs in

manifold systems, where reductant

and sample are mixed in a confined

tube and where generated hydrogen

inevitably results in bubble formation

and pressure increases.

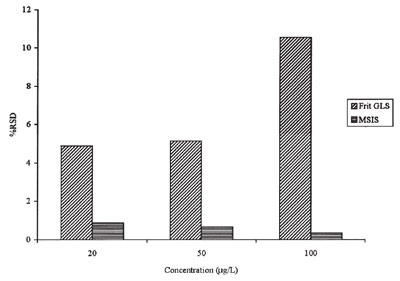

Figure 3 - Comparison of %RSD for the MSIS versus a frit-based gas–liquid separator.

Detection limits for hydride-forming

elements have values of 30 pg

mL–1 for arsenic (this work) and selenium.

The MSIS, unlike frit-based

gas–liquid

separators, delivers performance

similar to a conventional

nebulizer-spray chamber in that the

relative standard deviation (RSD)

decreases with concentration. Frit-based

gas–liquid separators, on

the other hand, show an alarming

increase in RSDs as the concentration

of analyte increases (Figure 3,

adapted from Ref. 14). Furthermore,

operation of the system for extended

periods of time does not lead to the

buildup of droplets in the injector

and, in this respect, the device

acts somewhat like a baffled cyclonic

spray chamber.

Several features of the MSIS have

attracted the interest of a number of

laboratories. The Canadian Association

for Environmental Analytical

Laboratories (CAEAL) has approved

its use for application to the determination of elements in sludges, biosolids,

soils, drinking waters, and wastewaters.

Benefits of the MSIS are 1)

elimination of single-element

technology

(quartz furnace, for example)

and 2) improvement in turnaround

time for sample processing. Data for

two different sample types, run on

an Optima 4300DV (PerkinElmer,

Shelton, CT) operating in axial

viewing mode, have been presented

here. The first sample type was a

water pollution trace metals performance

testing standard (Wibby

Environmental, Golden, CO), and

the second a metals in sewage sludge

certified reference material (CRM)

(Resource Technology Corp., Laramie,

WY).

Results and discussion

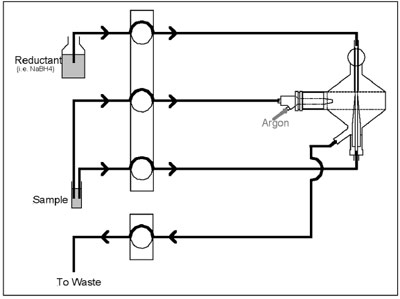

Figure 4 - Dual-mode flow scheme.

The results in Tables 1 and 2 reveal

the quality of data provided by the

MSIS operating in a routine fashion

using dual-mode operation (Figure

4). The Optima 4300 used relatively

short (1–5 sec) instrument-selected

integration times, indicating the

type of performance that could

be expected from an instrument

operating in a typical contract or

municipal laboratory. Results are

almost uniformly of high quality;

only in the sewage sludge standard

reference material does the value

for antimony vary significantly from

the expected value (this discrepancy

has been noted by others, who

report values lower than the certificate),

and the value for barium in

the same sample exhibits unusually

large standard deviation for reasons

that are not clear.

Conclusion

The MSIS is a robust device for the

determination of trace hydride-forming

elements in a production

laboratory. One of the authors

(P. Cheese) has been using it on

a routine basis for more than two

years in the vapor-generation

mode for the determination of As,

Sb, and Se, where it has delivered

satisfactory results in conformity

with CAEAL requirements.

For these elements, the required

method detection limits could not be achieved using standard nebulization.

Dual mode is not used

in the particular case of the environmental

laboratory since boron

must be reported in samples. The

MSIS, coupled with the ICP emission

instrumentation, has enabled

the laboratory to meet turnaround

time requirements, illustrating

how the MSIS delivers efficiency,

as well as accuracy, for the routine

environmental laboratory.

References

- Browner, R.F.; Boorn, A.W. Anal.

Chem. 1984, 56, 787A–98A.

- Sharp, B.L. J.Anal. Atom. Spectrom.

1988, 3, 613–52.

- Sharp, B.L. J.Anal. Atom. Spectrom.1988, 3, 8753–886.

- Nakahara, T.Prog. Anal. Atom. Spectrosc.1983, 6, 163–223.

- Le, X.C.; Cullen, W.R.; Reimer, K.J.;

Brindle, I.D. Anal. Chim. Acta 1992,

258, 307–15.

- Rigby, C.; Brindle, I.D. J.Anal. Atom.

Spectrom. 1999, 14, 253–8.

- Brindle, I.D.; Zheng,S. Spectrochim.

Acta, Part B1996, 51, 1777–80.

- Thompson, M.; Pahlavanpour, B.; Walton,

S.J. Analyst1978, 103, 568–79.

- Wolnik, K.A.; Fricke, F.L.; Hahn,

M.H.; Caruso, J.A. Anal. Chem.

1981, 53, 1030–4.

- Huang, B.; Zhang, Z.; Zeng, X. Spectrochim.

Acta, Part B 1987, 42, 129–37.

- Fengzhou, Q.; Guoying, G.; Chun, X.

Appl. Spectrosc.1991, 45, 287–92.

- Chen, H.; Brindle, I.D.; Le, X.C.

Anal. Chem.1992, 64, 667–72 and

references cited.

- Brindle, I.D.; Zheng, S. Spectrochim.

Acta, Part B 1996, 51, 1777–80.

- McLaughlin, R.L.J.; Brindle, I.D.

J.Anal. Atom. Spectrom.2002, 17,

1540–8.

- McLaughlin, R.L.J.; Brindle, I.D. Multimode

Sample Introduction System.

U.S. patent. Patent no. 6,891,605;

May 10, 2005.

Mr. McLaughlin, Ms. Ding, Mr. Ptolemy,

Ms. Conn, and Dr. Brindle are with the

Chemistry Department, Brock University,

St. Catharines, Ontario L2S 3A1, Canada;

tel.: 905-688-5550; fax: 905-682-9020;

e-mail: [email protected]. Ms. Cheese

is with the Niagara Regional Environment

Laboratory, The Regional Municipality of

Niagara, Thorold, Ontario, Canada.