Analytical laboratories are increasingly

challenged to improve data quality and

increase sample throughput. Exploration

of new ways to meet these requirements

has generated considerable interest in liquid chromatography systems utilizing

sub-two-micron (STM/<2 μm) column

technology. Providers of these instruments

claim reduced run times,

improved resolution, as well as other performance

enhancements.

Because questions have been raised concerning

the accuracy and specificity of some

of these claims, there has been a need for

objective criteria by which to gauge performance

of the various STM-capable LC

instruments. In the article in Ref. 1, authors

from a large pharmaceutical company outline

what they consider to be levels of performance

indicative of the potential of

STM technology. Their criteria include:

- Demonstrating instrumental capability for generating high LC flow rates for faster separations while minimizing increases in backpressure

- Utilizing elevated temperature to reduce separation times

- Accommodating all HPLC and STM-LC operational modes on a

single instrument and facilitating use of HPLC methods without the need for revalidation - Achieving separation efficiencies close to theoretical predictions

- Demonstrating the high-speed STM capability without compromising precision or sensitivity.

To these can be added:

- Maximizing sample throughput by minimizing cycle times

- Ensuring ease of use

- Providing robust system and data security

- Minimizing downtime through proactive diagnostic monitoring and maintenance.

Defining terms

Rapid Resolution liquid chromatography (RRLC, Agilent Technologies, Palo

Alto, CA), also known as ultra high pressure chromatography (U-HPLC) or

ultrafast LC (UFLC), are the terms used

to designate LC applications employing

STM columns with 1.0–4.6 mm i.d.

Pump pressure

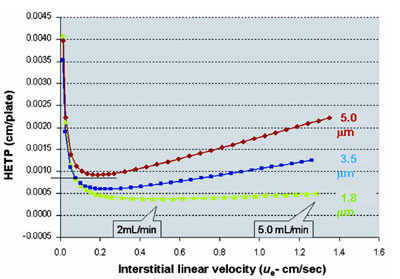

LC run times are primarily a function

of flow rate. With 3.5-μm or 5.0-μm

column packing, increases in linear

velocity beyond approximately 1.0

mL/min are accompanied by decreases

in column efficiency, which negatively

affects resolution. At flow rates

of about 2.0 mL/min, the decrease in

column efficiency for 3.5-μm and 5.0-μm particles is roughly 15% and 40%,

respectively. At a flow rate of 5.0

mL/min, the corresponding losses are

40% and 65%, respectively. This is

not the case for STM columns, for

which the efficiency remains fairly

constant over the same flow rate range

(Figure 1). As a result, STM columns

make it possible to shorten run times

considerably without compromising

resolution. (A 5–10 fold run time

decrease is typical, even without increasing temperature.) Sustaining

faster linear flow requires adequate

pumping capacity.

Figure 1 - Column efficiency at increasing flow rate for conventional HPLC vs STM-LC

columns. Unlike columns with 5-μm or 3.5-μm packing, STM-packed columns are efficient at high

linear flows and realize significant gains in analysis speed, typically 5–10× without changing temperature.

The STM column used here is a Zorbax 1.8-μm RRHT (Agilent Technologies) with 4.6

mm i.d. Experiments were performed on an Agilent 1100 series binary LC system.

At a given pumping pressure, a

decrease in packing particle size will

cause a corresponding drop in flow

rate. To overcome this effect, additional

increases in pumping pressure

are needed. Moreover, as linear speeds

increase, more stringent control of

flow rate variations and other deviations

in chromatographic dynamics

are necessary to maintain acceptable

precision. These conditions can be

met by a binary pump capable of producing

pressures up to 600 bar and

flow rates up to 5 mL/min. Perturbations

to constant flow are held within

narrow limits by the pump’s electronic

dampening control system. The result

is precisely reproducible chromatographic

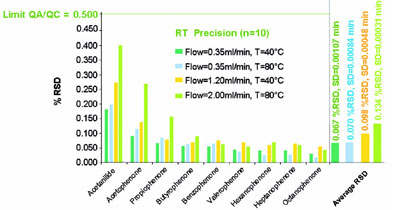

performance (Figure 2) as well

as lower baseline noise.

Figure 2 - Maintaining precision despite significant changes in flow rate and temperature. The

1200 series RRLC is equipped with electronic dampening of the system pump piston to minimize flow

rate fluctuations and electronic controls that hold temperature constant to within ±0.05 °C. These

system constraints also lower pump and heater contributions to baseline noise.

While brute pumping force is required

to generate the pressures needed for

faster chromatographic flow rates,

improvements in pumping efficiency

need to be considered as well. Optimizing

the instrument configuration to

minimize its contribution to the overall

backpressure enables greater utilization

of the pump’s capacity for generating

faster flows. Reducing the load on the pump also contributes to longer system

and component life and lowers both

maintenance downtime and operating

costs. To that end, an RRLC system

incorporates additional pressure reducing

characteristics such as:

- More efficient packing of the column and the use of STM columns with particle size distributions designed for pressure reduction (Zorbax 1.8-μm RRHT columns)

- Utilizing system-connecting capillaries with internal diameters and lengths that produce lower backpressure without increasing peak dispersion

- Autosampler valving and electronic controls designed for minimal injection pressure spikes.

The combination of higher pumping

capacity and system-engineered pressure

lowering enables an RRLC system

to operate efficiently over a flow

rate range of 0.05–5 mL/min, giving

linear flow rates of up to 16 mm/sec at

absolute flow rates of up to 2.4

mL/min (5 mL/min) on 2.1-mm (3-mm) i.d. RRHT columns.

Temperature

Because of its inverse relationship to

mobile phase viscosity, temperature is

another parameter that can be manipulated

to increase flow rate. (This may

not apply to non-Newtonian fluids

such as polymers and substances that

form immobilized bridged networks

such as gels.) This is especially the

case for important chromatographic

solvents such as water and alcohols

that exhibit strong intermolecularly

bonded networks that are considerably

weakened, with commensurate reduction in viscosity as the temperature

is increased.

The equation t/N ∝ η, which

describes the relationship between

temperature and viscosity, merits further

attention (t = temperature, N =

theoretical plate number, and η is viscosity).

Rearranging the terms t/η∝N

yields an expression indicating that

column efficiency increases rapidly

with increasing temperature since an

increase in t is accompanied by a

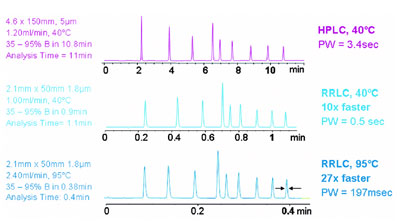

decrease in η. Figure 3 illustrates the

run time reductions gained by the use

of an STM packing in a narrow-bore/short-column format and the

additional reductions realized by running

this setup at elevated temperature.

Note that the decreases in run

times are achieved with resolution

comparable to HPLC. In certain

applications, such as LC-electrospray ionization (ESI)-MS, elevating the

temperature can also improve sensitivity

by increasing the efficiency of

nebulization and desolvation in the

electrospray ionization process.

Figure 3 - Maximizing run time reduction. Performing STM-LC in a short, narrow-bore column

at modestly elevated temperature achieves a tenfold decrease in run times on the 1200 series RRLC.

Using the same chromatographic configuration and elevating the temperature results in a 27-fold

increase in analytical speed compared with HPLC performed on a standard-bore column with a standard

particle size packing. STM-LC/temperature gains in analytical speed do not come at the expense

of resolution, sensitivity, or precision, which are comparable to the corresponding HPLC method.

High-temperature LC introduces a

set of constraints that must be properly

managed to avoid potentially

counterproductive effects. First and

foremost, the column packing

chemistry must be thermally stable.

Performance specifications for Zorbax

Stablebond C18 columns used

in the experiments presented here

demonstrate long-term stable operation

at temperatures up to 90 °C

and beyond. The LC column temperature

can be rapidly elevated by

means of a thermostated column

compartment equipped with Peltier-heating

technology. A low-volume

heat exchanger is employed to minimize

peak broadening on narrow-bore

columns.

A second Peltier-controlled heat

exchanger incorporated postcolumn

forms a feedback loop with the flow

cell temperature sensor, ensuring optimal

thermostating of the eluent and

the elimination of temperature-induced

noise in the detector. Low-noise

electronics complement the flow

cells that have been redesigned to

maximize sensitivity. Postcolumn cooling

coupled with fast run times also

significantly reduce the probability of

degradation by limiting analyte residence

time at elevated temperature.

Accommodating conventional HPLC and RRLC operational modes

Instrument flexibility is an especially

important attribute in a period of significant

technology transition. The

ability to accept both narrow- and

standard-bore columns eliminates the

need for separate HPLC and RRLC

instruments. Users can continue to

run current HPLC methods, maintain

the existing work flow, and meet regulatory

requirements while simultaneously

making the transition to RRLC.

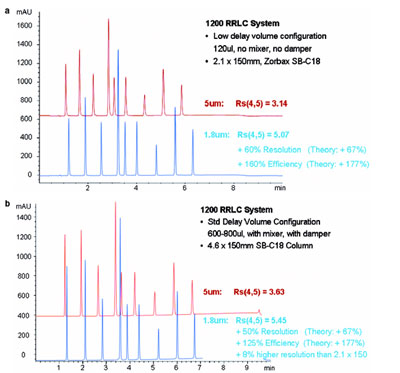

Figure 4 - Selectable delay volume avoids retention time mismatch when migrating methods from

HPLC to RRLC. RT shifts of up to 25% can occur when (a) an inappropriately low delay volume is

used for running RRLC on standard-bore columns. The RT discrepancy limits compatibility between

HPLC and RRLC applications and confounds peak tracking, requiring method revalidation. Selection

of the appropriate 600–800 μL standard delay volume (b) for both RRLC and conventional HPLC

methods run on standard-bore columns aligns run times, eliminating the need for method revalidation.

The lower 120-μL delay volume is reserved for narrow-bore column LC and LC-MS applications.

Adapting standard-bore column

methods to narrow-bore columns

ordinarily results in significant

alterations in retention time.

(Shifts as large as 30% have been

documented.) This large displacement

creates considerable uncertainty

with respect to peak identification, necessitating method

revalidation (Figure 4a). One way

to overcome this problem is to

employ selectable delay volumes: 600–800 μL for standard-bore

columns and 120 μL for narrow-bore

columns. Using the standard

delay volume eliminates the

HPLC-to-RRLC retention time

displacement, which is typically

held to <2%. As a result, existing

HPLC methods can be executed

without revalidation, and a

method changeover from HPLC to

RRLC often requires as little as 5

min (Figure 4b).

Figure

5 - Near theoretical separation efficiencies for STM-LC in both a)

narrow-bore and

b) standard-bore columns. 1200 RRLC performance in standard-bore columns

shows no sacrifice in

chromatographic efficiency as a result of a thermal mismatch between

mobile phase and column. (Such a

thermal mismatch would cause band broadening due to temperature

gradients across the column radius.)

The data shown here demonstrate nearly comparable column efficiency and

resolution, approaching theoretical

values for both standard- and narrow-bore STM columns.

Apparatus/experimental conditions—Test sample: set of nine compounds,

100 ng/μL each, dissolved in acetonitrile (ACN). 1)

Acetanilide, 2) acetophenone, 3) propiophenone, 4) butyrophenone, 5)

benzophenone, 6) valerophenone,

7) hexanophenone, 8) heptanophenone, 9) octanophenone. Instrument: 1200

Series RRLC with

binary SL pump, high-performance Autosampler SL, thermostated column

compartment, diode array detector SL (13-μL cell, 20-Hz data acquisition rate slit: 4 nm, signal: 245 nm). Columns: 4.6 and 2.1

× 150 mm SB-C18, 5 μm and 1.8 μm. Solvent A: H2O + 0.1% trifluoracetic acid (TFA). Solvent B:

ACN + 0.095% TFA. Gradient: 50–95% B in 7 min, hold over 1 min. Stop time: 10 min. Flow rate:

1.5 mL/min. Injection volume: 3 μL. Wash: 5 sec. Temperature: 50 °C.

Achieving separation efficiencies close to theoretical prediction

Run time reduction is not the only

objective of STM technology. The

term “rapid resolution” indicates

that improved separation efficiency

is also an important objective.

Figure 5a and b compare runs on 5-μm and 1.8-μm Zorbax 2.1 × 150 mm

and 4.6 × 150 SB-C18 columns,

demonstrating efficiency gains close

to theoretical prediction on both

narrow- and standard-bore columns.

Figure 5 also demonstrates that the

highest absolute resolution is

achieved on 4.6-mm columns, which

show an inherently higher efficiency

than 2.1-mm columns.

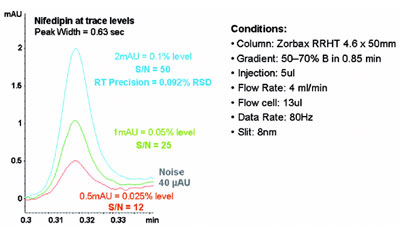

Figure 6 - Accurate impurity quantitation with rapid run times. Under ultrafast LC conditions,

the 1200 Series RRLC equipped with an Agilent DAD/MWD SL allows accurate quantitation of

impurities and side products at levels smaller than 0.05% of the main compound(s).

As retention times decrease, peaks

narrow (0.2–1 sec widths are typical)

and detection sampling rates must be

increased to preserve resolution. Use

of a low-noise diode array detector

(DAD) that can sample up to 80 Hz

makes it possible to routinely

achieve a S/N >10 at 0.5 mAU or

0.03% level, without dispersing

peaks by inappropriate low sampling

rates. This is in excess of the sensitivity

required for quantification of

pharmaceutical side products below

the critical 0.05% of the main compound

(Figure 6). Table 1 provides

further insight into the tradeoff

between data sampling rate, data

quality, and sensitivity. It shows that

a properly designed LC system can

provide significant flexibility to

adjust these parameters for various

application requirements.

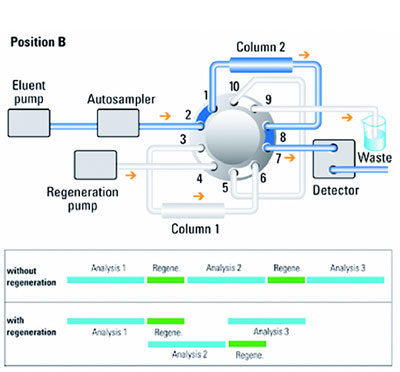

Fast run times: No assurance of high analytical throughput

Minimizing turnaround time is vital if

the savings from fast run times are to be

translated into high-volume sample

throughput. One approach to reducing

cycle times for high-throughput operations

is called alternating column regeneration

(ACR). This is a tandem, dual-column

configuration in which one

column is flushed and equilibrated while

the other performs a chromatographic

separation. ACR can reduce cycle times

by as much as 50% and produce throughputs

of more than 2000 samples per day.

ACR is enabled by means of a two-position/10-port valve system that

controls the timing and fluid paths

required for each phase of the chromatography

and/or column regeneration

(Figure 7). Because column flush and regeneration intervals are typically

shorter than analysis times, additional

means may be employed to further

shrink cycle times. Examples

include using an automatic delay volume

reduction that bypasses the sampling

assembly directly after the sample

has been injected and before the

gradient is introduced onto the

column (6 μL on the 1200 highperformance Autosampler SL) and

the ability to prepare the next injection

while the analysis takes place in

bypass mode, which is typically

referred to as overlapped injections.

Figure 7 - ACR-enabling two-position/10-port valve system.

ACR saves up to 50% of cycle time by utilizing parallel

column wash and regeneration, overlapped injections, and

accelerated sampling operations. Throughputs of more than

2000 samples/day can be achieved.

Reducing the intervals for operations

such as sampling and column

regeneration requires additional

measures to ensure that injections

remain precise and that carryover

between successive runs is minimized.

In certain instances, both

objectives can be facilitated with

the same technology solution. For

example, directing solvent flow

through the sampling assembly

(needle, loop, and metering device)

ensures continual flushing of the

internal surfaces. Simultaneous

external washing of the needle

helps prevent contamination of the

needle seat. Automatic additional

valve switches at different programmable

or automatic time points

provide the means for further flushing

persistent residues from the system.

High-throughput operations

are also beneficially supported by

the use of large solvent reservoirs

that permit unattended operation

for extended periods.

Control, compliance, usability, and servicing issues

System design that incorporates robust

user support helps to maximize performance

and ease of use while minimizing

downtime and operating costs. Especially

useful are instrument controller

enhancements such as highly readable

displays and the elimination of time-wasting

routines such as those requiring

system restarts whenever a configuration

is changed. Advances in electronics

make a faster software response possible,

and the extension of centralized control

to a larger universe of instrument components.

Controllers that incorporate

these innovations enable more rapid and

comprehensive data management (analysis,

retrieval, and review) and improved

system navigation.

LC instruments at the cutting edge now

offer a multiplicity of interactive help

functions that gauge performance;

proactively indicate when maintenance

is needed; and provide straightforward,

user-guided diagnostics. These routines

increase the efficiency with which the

instrument asset is managed by implementing

timely parts replacement and

rapid deployment of the requisite servicing

resource, when necessary.

A number of measures are increasingly

seen as intrinsic to secure and compliant

instrument and laboratory operations.

These include data loss protection in

the event of a communication interrupt

and electronic tags that unambiguously

track system parameters. Data and system

security are addressed through multiple

layers of protection, including

Internet firewalls, user control of communications,

end-to-end data encryption,

and compliance with network

security. Access is typically password

protected and can be ranked according

to a system of privileges.

Conclusion

The data presented here demonstrate

unequivocally that the 1200 series

RRLC meets the range of criteria for

delivering the full performance

potential of STM

technology as well as supporting

conventional HPLC.

It also shows that the system

provides an easy and secure

transition between the two

technologies. This flexibility

derives from the instrument

platform design that comprises

a matrix of functional

modules that can be configured

and reconfigured to

meet a diversity of analytical

LC applications. The various

configurations constitute a

continuum or glide path

across performance regimes

that address current and

anticipate future needs.

Users entering the 1200 series continuum with an 1100 series

emulation or by upgrading an 1100 series

instrument with 1200 series modules are

well positioned to reconfigure their system

for RRLC operations. Naturally, one

can start out with a fully equipped 1200

RRLC system configuration.

Reference

- Kofman, J.; Zhao, Y.; Maloney, T.; Baumgartner, T.; Bujalski, R. Ultra-high performance liquid chromatography: hope or hype? http://www.chem.agilent.com/Library/articlereprints/Public/5989-5169EN-lo.pdf.

Dr. Frank is Application Chemist, Dr.

Gratzfeld-Huesgen is Application Chemist, and

Dr. Schuette is Program Manager 1200 Series

Rapid Resolution System, Agilent Technologies,

Hewlett-Packard-Str. 8, 76337 Waldbronn,

Germany; tel.: +49 7243 602820, ext.

510; e-mail: [email protected].