In 1981, two research scientists from

IBM’s European research facility

in Rueschlikon, Switzerland, made

a discovery that would help change

the face of the world today. With the

invention of the scanning tunneling

microscope (STM),1 Gerd Binnig and

Heinrich Rohrer gave birth to a family

of techniques that have allowed

scientists to study materials from the

atomic level upward. Five years later

came an even more powerful invention,

the atomic force microscope (AFM).2 Binnig, now collaborating

with Cal Quate and Christoph Gerber,

produced the instrument that

was to become the father of scanning probe microscopy (SPM), spawning

a number of metrological tools that

were referred to as “the picks and

shovels of nanotechnology.” Unlike

the usual timelines of instrumentation

development, where an idea may

take 15 or more years to transition

from a concept to development tool

and finally to a routine analytical

solution, the AFM came along at

the start of the explosive growth

of the semiconductor industry

defined by Moore’s Law. In 1975,

Gordon Moore of Intel (Santa

Clara, CA) predicted that data

storage capacity and processing

power would double every two

years. To keep up with this model,

and sometimes exceed it, industry

required a means to locate and

measure the size and performance

of chips that were being packed

more and more densely onto silicon

wafers. The AFM had found

its first niche.

The advantage of the AFM

was its ability to study all types

of material in a variety of environments,

from air to liquid, ambient

pressure to ultrahigh vacuum. This

has led to AFM now being found in

the laboratories of multiple scientific

disciplines. Some of the most

exciting steps forward in recent

years have been seen in the life

sciences, where AFM techniques

have been used to enhance the

knowledge of molecules in vitro,

with the AFM probe being able

to look at individual or moleculeto-

molecule properties.

There are many great scientists

who have spent their lives working

in SPM research, but few have

had the impact in applying these

technologies as Kumar Wickramasinghe.

In the 1980s and ’90s,

Dr. Wickramasinghe was working

in the T.J. Watson Research

Center (Yorktown Heights, NY),

where he pioneered many applied

techniques that were to benefit

IBM’s work in semiconductor

manufacture. Having been one of

the first scientists to apply tapping

mode for imaging surfaces, Dr. Wickramasinghe

developed it to invent

other now established techniques

such as magnetic force microscopy,3

electrostatic force microscopy,4 Kelvin

probe microscopy,5 scanning thermal

microscopy,6 and the apertureless near-field optical microscope.7

Freed now from project work, Dr.

Wickramasinghe has been able to

go back to his first love, practical

research. For the past few years, he

has been able to focus on new areas

in which to apply scanning probe

techniques. Working with postdoctoral

research fellow Kerem Udal,

Dr. Wickramasinghe has published

a paper that details his work using

AFM to sort and deliver molecules at

extremely high speeds.8

Rather than the AFM being applied

as a microscope, it is now being used

as a tool that acts like a printer,

writing onto a surface. In the late

1990s, the Mirkin group at Northwestern

University (Evanston, IL)

first applied AFM in a technique called dip-pen nanolithography

(DPN),9,10 which was developed to

put down a variety of chemical compounds

onto a variety of substrates.

According to Dr. Wickramasinghe,

DPN was analogous to a quill pen,

with little control of the deposition

rate since the mechanism of writing

was through diffusion. Also, control

was related to the speed at which

the pen was moved over the substrate,

and the process was

stopped and started by the

pen being lifted to and from

the surface.

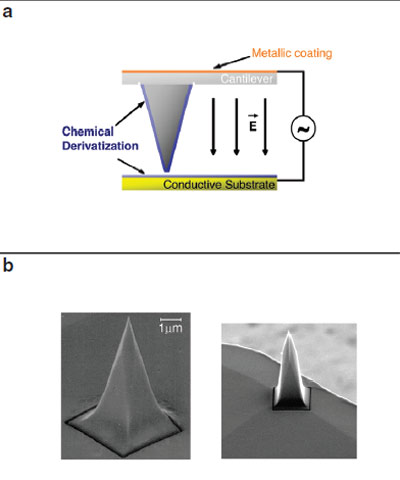

This latest approach, however,

works more like an inkjet

printer. A new type of probe is

used that is conical in shape;

where it connects to the cantilever,

IBM’s design incorporates

a reservoir to supply the

molecular ink. Not only can

the device write, but it can

also remove molecules from

the substrate.

Figure 1 a)- Scheme of an AFM probe used in

this study with the associated electric field. b) SEM

images of a modified cantilever.

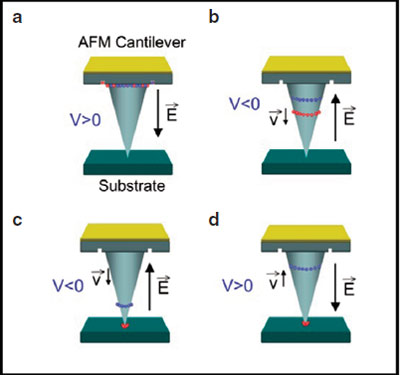

Figure 2- Depending on the voltage pulse and

polarity, molecules (red) may be released from the tip

and deposited on the substrate.

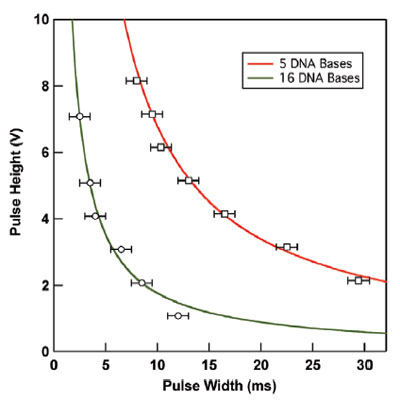

Figure 3- The different mobilities of 5- and 16-

base DNA fragments enable their separation using

this AFM-based electrophoretic technique.

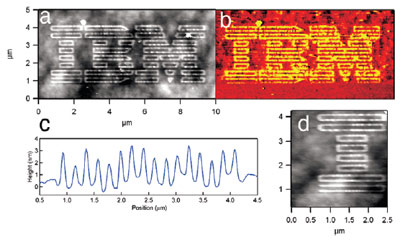

Figure 4- Topographic (a) and lateral force (b)

images showing controlled surface patterning with

5-base-long DNA fragments. Line scans (c and

d) show a mean height of 2.4 nm and line width of

between 59 and 79 nm.

The technique works because of

the thin film of water found on

the substrate and on the probe

itself (Figures 1–4 display the

ultrafast molecule sorting story). By

applying a field between a conducting

cantilever and probe and the

conducting substrate, it is possible to

exploit the electrophoretic mobilities

of molecules. Thus, by varying

field strength and polarity, it is possible

to precisely control deposition

and removal of the molecules

from the surface. When this is combined

with the positioning capabilities

of a modern AFM system, it is

possible to envision a method that

writes features five times smaller than

today’s e-beam lithography and 10

times smaller than photolithography.

It is the control of the thin film of

water through control of the humidity

of the experiment that makes this

method work.

Understanding the chemistry of

the process is also extremely important.

Close control of the probe

and surface chemistries is required

to ensure the molecules are immobilized to prevent diffusion. In

the experiments used to illustrate

this inkjet concept of writing, Dr.

Wickramasinghe’s team investigated

single-stranded DNA fragments.

Deposition was confirmed

using lateral force microscopy

(LFM) because it is particularly

sensitive to frictional change, thus

readily “seeing” the sticky molecules

on the smooth substrate.

The electrophoretic AFM method was

compared to traditional capillary electrophoresis.

The transfer times using

AFM were dramatically reduced: A

15-base-long strand of DNA could

be transferred in 5 msec compared to

170 sec in a conventional 8.5-cm-long

microfluidic channel.

The potential impact of this work

ranks alongside some of Dr. Wickramasinghe’s

other achievements.

The method has enabled the acceleration

of molecular separation,

and transfer has been speeded up

by several orders of magnitude.

Dr. Wickramasinghe believes this

wi l l have an impa c t on futur e

research in biology and medicine.

For example, DNA sequencing will

be speeded up through reduction

in sample size. The method is very

scaleable using either multiple-tip

arrays or multiple reservoirs with

different molecules.

It is work like this that makes

exploring the field of SPM so exciting.

With nanotechnology already

being part of today’s world, it is the

work of scientists like Dr. Wickramasinghe

that emphasizes the benefits

of working on the nanoscale

to enhance the quality of life today

and for generations to come. So

what will the next 25 years bring?

The only restriction is the power of

our imagination.