The attempt to stabilize stationary

phases for use in gas chromatography is

ongoing. This is because lower detection

is increasingly required and, in

order for the detection system to provide

high performance, the risk of contamination

must be minimized. Using

stabilization technology, the breakdown

of stationary phases was reduced, resulting

in low-bleed stationary phases with

tight specifications.

One of the parameters that initiates stationary

phase breakdown is the internal

surface of the GC capillary. Modifying

the surface made it possible to stabilize

stationary phases by a factor of 4–10

lower breakdown. This also resulted in

higher operating temperatures for such

phases as the UltiMetal column (Varian

Inc., Middelburg, The Netherlands) for

simulated distillation applications.

In the present study, arylene-stabilized

5% phenyl/95% methyl polydimethylsiloxane (PDMS) type

phases were tested in a high-temperature GC using fused-silica

columns that were deactivated in a way similar to the

UltiMetal columns. The result is an extremely stable and

low-bleed phase, the VF-5ht (Varian), which is capable of

operating at up to temperatures of 400 °C.

High-temperature capillary columns

Various approaches were taken in the past for performing

high-temperature separations. Columns with an aluminum

outside coating were commercialized 15–20 years ago. In

theory, these columns should have been very temperature

stable and easy to handle. Practical experience with the

aluminum-coated columns revealed, however, that they

became fragile after repeated temperature programming. On

the other hand, isothermal operations performed well. The

difference in thermal expansion coefficient has been the

main cause of this problem.

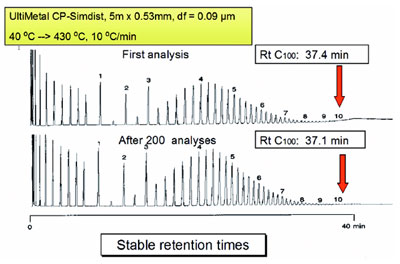

Figure 1 - Retention time stability following long-term, high-temperature exposure using

UltiMetal column coated with 100% PDMS.

Alternative solutions were discovered in 1990,1 when a new

deactivation technology was introduced for the deactivation

of metal capillaries. The resulting columns could be

used at up to very high temperatures. Figure 1 shows an example of such a column for a hydrocarbon sample running

up to C100. The column was used for 200 runs up to

430 °C, and retention time for C100 was altered from 37.4

to 37.1 min. This meant that the majority of the stationary

phase was rendered in the column. This is typical of

UltiMetal Simdist columns, i.e., very low bleed and high

stability. The columns are coated with 100% PDMS-type

phases, providing the best match with boiling-point-type

elution, as required for simulated distillation.

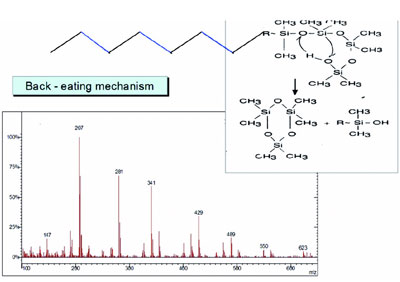

Figure 2 - Breakdown mechanism of siloxane stationary phases: formation

of cyclic degradation products.

Surface stabilization

In order to create a surface that stabilizes stationary

phases, the breakdown mechanism of stationary phases

must be known. Figure 2 depicts the most common mechanism

of siloxane breakdown: A terminal silanol attacks its

own chain and a cyclic (volatile) degradation product is

formed. This volatile degradation product can be detected

by any sensitive detection system. There will be various

ring sizes formed, which can be identified via MS by the

different masses.

There are three mechanisms responsible for the formation of

the terminal silanol group:

- Breakdown initiated by the silanol groups in the stationary phase.

The greater the amount of stationary phase, the more breakdown (bleed)

will be obtained, which is usually why the bleed increases linearly with

the amount of stationary phase in the column.

- Breakdown by the silanols formed upon application. When a

column is operated in a GC, there always will be water molecules

entering the system. This occurs via the carrier gas, leaks, injection,

and the septum. These water molecules will hydrolyze the siloxane chain

and split the siloxane molecule, forming terminal silanol groups. This

again initiates the breakdown and bleed. This can be controlled for

different setups since it depends mainly on the purity of the carrier

gas and how the system is put together and maintained.

- Breakdown initiated by the reactive surface silanol groups. The amount in these groups is determined by the surface and the surface deactivation.

Items 1 and 2 can be easily optimized/minimized using stationary

phase stabilization technologies as well as gas filtration

and thorough leak checking. Item 3 has to be optimized

via the internal column surface.

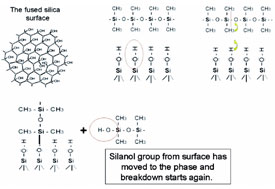

Figure 3 - Surface silanol group transfers to stationary phase, forming

a terminal silanol group.

Normal deactivation using siloxane deactivation reagents

will always leave a number of silanol groups at the surface.

These can react with the stationary phase, forming a surface

bond, and the silanol group will then “jump” to the stationary

phase, as shown in Figure 3. The degradation process

reinitiates, as shown in Figure 2.

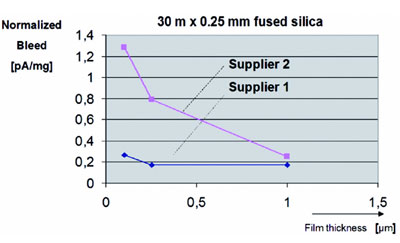

Figure 4 - Normalized bleed (bleed per mg stationary phase) for different

suppliers.

The impact of the surface can be visualized if we calculate the

bleed per milligram of stationary phase (normalized bleeding)

based on the specifications of different suppliers. It is clear

from Figure 4 that by decreasing the film thickness, the bleed

per milligram of stationary phase increases exponentially. This

is due to the impact of the fused-silica surface. Supplier 1 was

more successful at deactivating the reactive surface silanol

groups, resulting in a listing of lower-bleed specifications.

New deactivation of fused-silica surfaces

In addition to the standard siloxane deactivations of surfaces,

a new deactivation was introduced in 1990.2–4 This deactivation

was also applied to fused silica, which resulted in a new

method for extending the temperature stability of stationary

phases. By reducing the level of reactive silanol groups, this

contribution to degradation has been minimized.

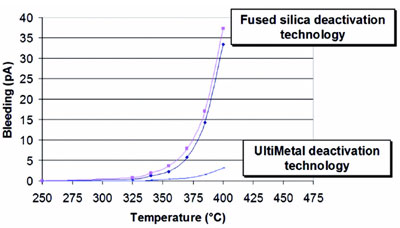

Figure 5 - Impact of column internal surface on stationary phase

degradation.

When coating stabilized stationary phases, there is a significant

improvement in thermal stability. Figure 5 shows a direct comparison of a similar layer of arylene-stabilized

stationary phase, VF-5ms (Varian), coated on a fused-silica,

deactivated surface, and the UltiMetal deactivation

technology. The result is lower degradation of the stationary

phase by a factor of almost 10. The phase stabilized

using this technology is the VF-5ht. These phases can be

used at much higher operating temperatures. Additionally,

when working at lower temperatures, there is hardly any

measurable bleed.

Column lifetime

In high-temperature analysis, column lifetime is often determined

by degradation of the stationary phase. Lower degradation

translates into increased lifetime. Furthermore, retention

times will be more constant, which allows easier

maintenance of integration parameters and calibration.

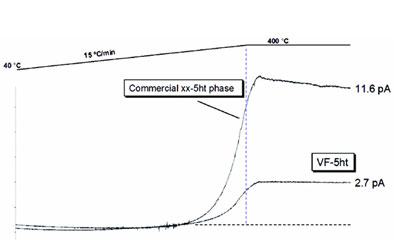

Although high-temperature phases that use fused silica are

commercially available, they are stabilized mainly by polymer

technologies. The effects of the fused-silica surface

have not been optimized, as shown in Figure 6. A comparison

was made of a 30 m × 0.25 mm fused-silica capillary

coated with a 0.10-μm high-temperature phase. There is a

significant difference in stationary phase degradation. For

high-temperature analysis, the loss of phase usually determines

the lifetime. This is significantly better for the VF-

5ht. When running different sample types, the difference

in column bleed is always seen when the upper temperature

is reached: The background of the VF-5ht is significantly

lower.

Figure 6 - Comparison of existing high-temperature phases with similar

siloxane composition.

Injection techniques

Most of the high-temperature applications deal with neutral

components. It is important to have a representative

sample on the column; an on-column injection technique

is recommended for this. With on-column injection, the

sample is introduced inside the capillary as a liquid. The

method results in minimal discrimination, since all material

injected onto the column will also elute from the column.

To apply the on-column injection technique, it is

important to have fused silica with a diameter of 0.32 mm in order to allow easy access of the syringe needle into the

capillary. This diameter is standard for the VF-5ht phase.

In addition, the phase is cross-linked and immobilized,

meaning that direct contact with liquids will not change

the column efficiency.

Split systems are also used for high-temperature operations.

If the split system produces a reproducible discrimination,

the technique will also produce acceptable data. Split injection

provides more flexibility with sample types. Column

diameters of 0.25 mm can be used, providing the highest separation

power.

The programmed temperature vaporizer (PTV) is a more

universal technique. It is growing in popularity and is applicable

for high-temperature analysis as well.

Impact of oxygen/water

Oxygen is generally not a problem in GC when analysis temperatures

are low. In some applications, air is used as the carrier

gas at temperatures up to 130 °C. Above 130 °C, the

impact of oxygen increases. When applications are run

higher than 200 °C, oxygen must be removed.

Water can also be a problem at lower temperatures and must

be eliminated. Because water forms terminal silanol groups,

it is the main cause of stationary phase breakdown. As the

reactivity increases with higher temperatures, the high-temperature

applications require ultradry conditions.

Therefore, leaks must be minimized and carrier gas must be

absolutely pure, preferably filtered with special filters before

the GC. Gas Clean filters (Varian) are highly recommended.

With the indicator in the filter, the risk of water

introduction is reduced to a minimum.

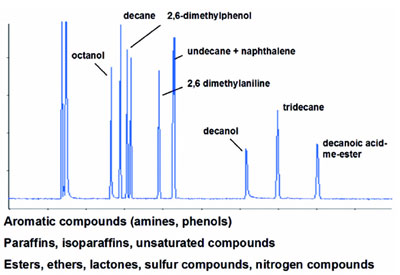

Figure 7 - Different classes of components that can be analyzed using

the high-temperature column.

Loadability/inertness

The high-temperature columns are coated with thin films to

have the lowest possible elution temperatures. The challenge to using thin films is always the loadability and the

inertness of the resulting column. The VF-5ht is a good

compromise. Generally, a wide range of compounds having

different functionalities can be analyzed (see Figure 7).

Highly polar compounds such as alcohols and free acids,

however, will exhibit nonsymmetrical peak shapes. The

majority of high-temperature applications involve neutral or

slightly polar compounds. It is recommended that highly

polar and heavy compounds be derivatized to improve chromatography

and volatility. When using thin-film-coated

columns, there is a constant risk of overloading, and samples

need to be diluted to minimize the overloading effects.

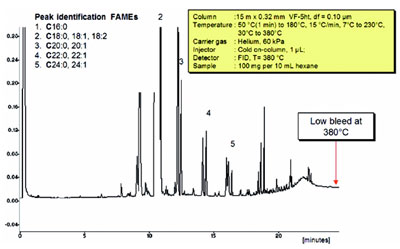

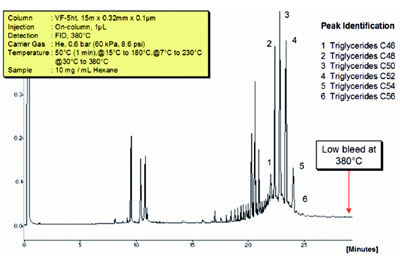

Figure 8 - Analysis of biodiesel according to ASTM D6584.

Applications

The main application area for the VF-5ht phase is for the

separation of high-boiling-point components/mixtures.

ASTM D6584 describes the analysis of biodiesel, which

requires high elution temperatures. Figure 8 shows the separation

of biodiesel using the VF-5ht phase. Up to temperatures

of 380 °C, virtually no bleed can be observed. On-column

injection is used for this application to elute the

heavy boilers with minimal discrimination. In this analysis

in particular, it is important to have good quantification.

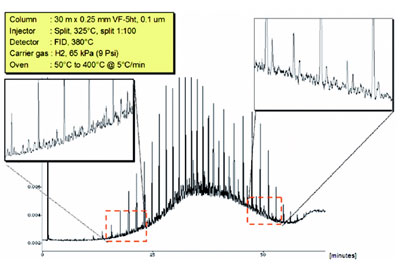

Figure 9 - Triglycerides of palm oil.

The same injection technique was used for the separation of

triglycerides. Separation is by carbon number (see Figure 9).

Since the column has a stabilized polyimide outside coating,

long-term operation at high temperatures will oxidize and

weaken the protective coating. The degree of oxidation

depends on the type of GC, position of the column in the

GC, temperature, and the time exposed. Although the VF-5ht phase on this surface can withstand temperatures of

400 °C, it is recommended that the column be as short as

possible at such high temperatures. High-resolution hydrocarbon

separations can be done using the 0.25-mm-i.d. column,

as demonstrated in Figure 10. The high efficiency of

the columns is also shown. In addition, at higher temperatures,

the VF-5ht phase remains very efficient.

Figure 10 - High-resolution separation of a wax sample.

Conclusion

The VF-5ht stationary phase offers extreme temperature stability,

permitting efficient, high-temperature separations.

The stability of the phase provides reproducible retention

times to allow a reduced number of calibration runs. Column

lifetime is significantly improved. It is important to ensure

that the GC system is absolutely leak free, and carrier gas

must be of high purity in order to gain the full benefit of

these phases for high-temperature separations.

References

- Buyten, J.; Duvekot, C.; Peene, J.; Mussche, P. Eleventh International Symposium on Capillary Chromatography, Monterey, CA, May 14–17, 1990; 91.

- Buyten, J.; Duvekot, C.; Peene, J.; Mussche, P. Int. Chromatogr.

Lab.1990, 2, 5. - De Zeeuw, J. Chrompack News1990, 17(2), 3.

- Schaller, H. Fat Sci. Apr. 1991, 93, 510.

- High Temperature Gas Chromatography. Chrompack, no. 03551, 1990.

The authors are with Varian Inc., Herculesweg 8, 4330 EA Middelburg,

The Netherlands; tel.: +31 118 671279; fax: +31 118 67235; e-mail: [email protected].