Assays that predict passive absorption

of orally administered drugs have

become increasingly important in the

early drug discovery process. A

molecule’s ability to be orally absorbed

is one of the most important aspects in

deciding whether it is a potential lead

candidate. The cell-based assays, like

those using Caco-2 cells, are common

functional models for drug absorption;

however, this labor-intensive and

expensive technique is often pursued

late in the drug discovery process.

Assays described by Kansy1 and Faller2

have addressed these issues by providing

rapid, low-cost, and automation-friendly

methods to measure a compound’s

passive permeability. These in

vitro assays have become an integral

part of early drug discovery because of

their simplicity.3,4 In vitro permeability

assays help predict the potential

bioavailability or in vivo absorption of

a molecule. This paper discusses the

benefits of enhanced throughput,

automation, and robustness of in vitro

permeability assays with progressive

plate technology.

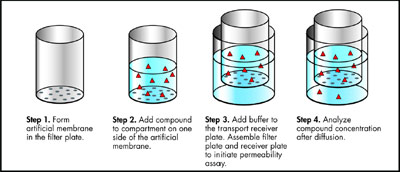

Figure 1 - PAMPA passive diffusion process.

The parallel artificial membrane permeability

assay (PAMPA) is a

noncell-based in vitro technique

used to predict the passive, transcellular

membrane permeability of

potential new pharmaceuticals.

Microplate filters impregnated with

mixtures of phospholipid/organic solvent

fit precisely into discrete

receiver wells to form 96 microdiffusion

chambers. Within the phospholipid

barrier, a concentration gradient

drives the passive diffusion of

molecules, which is the principal

mechanism of drug transport through

biological barriers (see Figure 1).

Data produced by these assays result

in a permeability estimate (effective

permeability, Pe). Fast, flexible, and

cost-effective compared to alternative

cell-based models, PAMPA also

enables the evaluation of different in

vivo absorption models by varying

pH or lipid composition.

Challenges

Traditional products for PAMPA had

limited handling capabilities with

standard laboratory robotics. Automated

assembly introduced trapped air

between the filter and buffer compartments,

reducing diffusion surface area;

receiver well shape limited shaking or

stirring capability; and inconsistent

evaporation necessitated the need for

controlled, humidified environments

due to inconsistent evaporation.

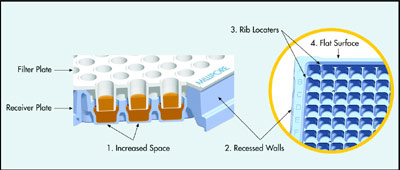

Figure 2 - PAMPA transport receiver design features.

A newly designed transport receiver

plate (Millipore Corp., Danvers, MA)

offers high data quality and throughput

for PAMPA. The molded receiver

plate has such built-in design features

(Figure 2) as increased diffusion space

(1), recessed side walls (2), rib locaters

(3), and a continuous flat top surface

(4) to help overcome many of the

challenges mentioned above.

Experiments

Handling consistency, assay flexibility,

and data reproducibility were

evaluated with standard automation.

Eighteen molded receiver

plates were tested for automated

assembly/disassembly and associated

cross-talk, evaporation, and occurrence

of trapped air. Tests were run

on three consecutive days with

three different automated liquid handlers (Packard® MultiPROBE®

II [PerkinElmer, Boston, MA], Tecan® Genesis™ [Zurich, Switzerland],

and Beckman® BioMek® FX

[Fullerton, CA]). Three machined

Teflon® (DuPont, Wilmington, DE)

receiver plates were used as controls.

Plate performance was evaluated

before, during, and after automated

handling and after overnight

incubation on the robot deck.

Cross-talk and trapped air

Cross-talk (cross-contamination)

between discrete adjacent wells was

measured fluorescently with a Spectrafluor™plate reader (Tecan).

Trapped air was checked visually on a

light box, and well-to-well evaporation

was measured using pathcheck on

the SpectraMax® Plus plate reader

(Molecular Devices, Sunnyvale,

CA). Fluorescent test solution or

buffer (300 μL/well) was dispensed in wells in a criss-cross pattern, and

cross-talk was calculated by dividing

relative fluorescence units (RFU) of

blank wells by RFU of adjacent fluorescent

wells (485-nm excitation/535-nm emission). Molded plates had no

cross-talk and controls averaged 22

wells per plate. Molded plates averaged

one trapped air bubble, while

controls averaged 12 per plate.

Evaporation

Final permeate absorbance is

required to calculate passive transport.

If permeate concentration and

absorbance increase due to evaporative

volume loss, the resulting

calculation leads to artificially

increased permeability rates.

Therefore, minimal and uniform

evaporation are critical for reproducible

and reliable data.

PAMPA incubations at ambient

humidity and temperature were

evaluated for overnight evaporative

volume loss. Based on a 300-μL

starting volume, outer perimeter and

inner well evaporation for the

molded plates was 4.5% ± 0.8% and

4.5% ± 0.6%, respectively (n = 18).

Machined Teflon control loss averaged

8.9% ± 3.8% and 4.6% ± 3.2%

(n = 3), a twofold and fivefold

increase in volume loss and standard

deviation, respectively.

Shaking and stirring

The diffusion rate of molecules

through a phospholipid barrier is

limited by the barrier and/or by

adjacent aqueous boundary layers

(ABL).5 Nonagitated in vitro ABLs

can be 10–100 times greater than

in vivo measurements. When the

ABL is thicker than the phospholipid

barrier, it becomes the rate-limiting

factor for the diffusion of

nonpolar, lipophilic molecules.

Therefore, agitation of the bulk

solution by shaking or stirring can

significantly reduce the ABL,

resulting in more accurate in vitro

permeability predictions.

- Shaking. Six molded plates were

assembled with the BioMek FX liquid

handler and evaluated for

cross-talk after overnight shaking

on the MicroMix5® (DPC, Randolph,

NJ) orbital shaker at

1200–1500 rpm (form 22, amplitude

5). One control plate was

static tested. Fluorescence was

measured with the Spectrafluor plate reader before and after assembly

as well as after overnight shaking.

Molded plates had no cross-talk,

and the control had seven

wells. Molded plates averaged 2.5

trapped air bubbles, and the control

had 22.

- Stirring. Six molded receiver plates

were assembled manually with

super-tumble stir disks (catalogue

no. VP 721F-1, V&P Scientific,

Inc., San Diego, CA) in every

well. Cross-talk was evaluated

after stirring for 1 hr (750 rpm) on

a VP 710C1 rotary tumble stirrer

(V&P Scientific). No cross-talk

was observed.

An integrity test was also performed

for potential stirring-related filter

damage. A lucifer yellow-buffer test

solution (150 μL) was dispensed to

filter plates. After 30 min of stirring

(300 rpm), permeate fluorescence

was measured with a Victor™ spectrofluorometer

(PerkinElmer) at

485/535 nm. Fluorescence of an

equilibrium plate (135 μL/well buffer

+ 65 μL/well test solution) and a

blank buffer plate were required to

calculate integrity. 1-(sample RFU-mean

blank RFU)/(mean equilibrium

RFU-mean blank RFU) = %

integrity. All stirred assemblies had

≥99% filter integrity.

Conclusion

As a result of design enhancements,

PAMPA can be a highly effective

way to characterize and optimize lead

candidates early in the drug discovery

pipeline. Being flexible, fast, low cost,

and automation-friendly,

PAMPA has become the emerging

method to complement cellular based

absorption models.

References

-

Kansy, M.; Senner, F.; Gubernator,

K. Physicochemical high throughput

screening: parallel artificial membrane

permeation assay in the

description of passive absorption

processes. J. Med. Chem. 1998, 41,

1007–10.

- Wohnsland, F.; Faller, B. Highthroughput

permeability pH profile

and high-throughput alkane/water log

P with artificial membranes. J. Med.

Chem. 2001, 44, 923–30.

- Di, L.; Kerns, E. Profiling drug-like

properties in discovery research. Curr.

Opin. Chem. Biol.2003, 7, 402–8.

- Brennan, M.B. Drug discovery (filtering

out failures early in the game).

Chem. Eng. News 2000, 78, 63.

- Kansy, M.; Avdeef, A.; Fischer, H.

Advances in screening for membrane permeability: high resolution PAMPA

for medicinal chemists. Drug Discov.

Today2004, 1, 349–55.

Mr. Kazan is a Biochemical Scientist, Bioscience

Div., Millipore Corp., 17 Cherry Hill Dr.,

Danvers, MA 01923, U.S.A.; tel.: 978-762-

5197; fax: 978-762-5386; e-mail:

[email protected].