Chloroplasts were successfully separated by centrifugation

in a sucrose density gradient into particle

fractions using a zonal rotor.1 Since then, various

aspects of the procedure have been used with different

swinging-bucket rotors. This technical article

describes the large-volume F10-6x500y rotor with

conical bottle and adapter assembly (Figure 1) that

was used in the Vortex 21K high-speed centrifuge

(Figure 2) for all centrifugal sample preparations

(FIBERLite Centrifuge Inc., Santa Clara, CA).

The conical bottles in the adapters (250 mL) were

used in place of swinging-bucket rotors for density

gradient separations and to collect sediment in the

small cone area of the conical bottles (Figure 3).

Standard round-bottom bottles were not used with

the fixed-angle rotors.

Figure 1 - F10-6x500y rotor with conical bottle and

adapter assembly.

Figure 2 - Vortex 21K centrifuge.

Figure 3 - Conical bottle and adapter assembly.

Methods and results

About 400 g of market spinach leaves were deveined

and blended for 15 sec in 500 mL of 0.4 M sucrose,

0.05 M tricine buffer at pH 7.4. The homogenate

was filtered through cheesecloth, and the filtrate was centrifuged for 10 min at 4000 × g (5000 rpm). The

pellet was resuspended in 250 mL of 0.3 M KCl, 0.05

M tricine, at pH 7.7, then pressed through a French

pressure cell (SLM Instruments Inc., Urbana, IL)

three times at 12,500 psi. The resulting homogenate

supernatant was centrifuged for 10 min at 4000 ×

g (5000 rpm) to remove the larger cell fragments.

The pellet was again diluted with 250 mL of 5% w/w

sucrose to make 250 mL homogenate sample containing

about 6.0 mg chloroplast per milliliter in the

5% w/w sucrose.

Each conical bottle was loaded with a stepwise

sucrose gradient of 70 mL per step made up in 0.15

M KCl and 0.05 M Tris buffer, pH 7.7. The sucrose

concentrations were layered in the centrifuge conical

bottles using a Pasteur pipet that reached to the

bottom of the bottle. The lightest step of the gradient

of 10% concentration was placed in the bottle

first. The second concentration, 30%, was layered

below the 10%, and finally the 50% concentration

was layered below the 30%. Care was taken not

to disturb the interfaces between the layers by

holding the tip of the pipet to the wall of the

bottle when removing it or introducing it into

the conical bottle.2

Immediately after the concentrations were layered

into each bottle, 40 mL of the homogenate

sample was layered in the top of each gradient to

prevent premature sample or gradient diffusion.

The bottles were then placed in the adapters and

installed in the rotor cavity. A slow acceleration/deceleration profile for the centrifuge was chosen to

prevent sample gradient mixing during acceleration

and or deceleration. The maximum speed of (10,000

rpm) 17,000 × g at 4.0 °C with a run time of 2.5 hr

was selected for the chloroplast separation.

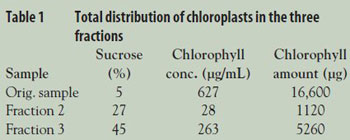

At the end of the run, three fractions were visually

observed, and they were removed from each bottle

by pipet. Spectrophotometric measurements of the

fractions were made at 680 nm. Fraction 1 at the top

of the bottle was removed first. This fraction represented

nongreen light scattering material. The visible

green fraction 2 in the center zone of the bottle

contained chlorophyll and was removed, and fraction

3 in the cone of the bottle that contained the

chloroplasts was removed. Each fraction was diluted

at a ratio of 1:2 with buffer and centrifuged at 4000

× g for 10 min to collect the sediment. Table 1 shows

the distribution of chloroplast in the three fractions.

Conclusion

The results presented in Table 1 show that good

separation of the fractions was accomplished, and a

substantial amount of each fraction was collected in

a single operation with the F10-6x500y rotor. The

conical bottles for all centrifugal sample preparations

including the density gradient separation of

the sample separation made it easy to determine the

relative amounts of chloroplast in each fraction. The

simplicity of use of the Vortex 21K high-speed centrifuge

was also noted.

The large-volume fixed-angle rotor with conical

bottles can be used successfully in place of a large-volume

swinging-bucket or zonal rotor to obtain

good separations by density gradient centrifugation.

References

- Brown, J.S.; Griffith, O.M. Year Book; Carnegie Institution:

Stanford, CA, 1971, 69; 705. - Griffith, O.M. Practical Techniques for Centrifugal Separations. FIBERLite Centrifuge, Inc.: Santa Clara CA, 2006; Vol. 1; p 40.

Dr. Griffith is Director of Research, FIBERLite

Centrifuge

Inc., 422 Aldo Ave., Santa Clara, CA 95954,

U.S.A.; tel.: 408-988-1103; fax: 408-988-1196; e-mail: [email protected].