Following an informal collaboration

with Affymax (Palo Alto, CA),

Agilent Technologies (Palo Alto,

CA), and Chem-Space Associates

(Pittsburgh, PA), studying electrospray

ionization 1 (ESI), the technology

invented by Prof. John Fenn,2

a simple technology called induction-based fluidics (IBF) (Nanoliter,

LLC, Henderson, NV)3 was

invented and patented.3 IBF charges

liquids, but without the adverse

electrochemistry inherent in ESI.

IBF has other merits as well. That

said, the charging of liquids has been

around for some time. Prof. Robert

Millikan employed it to determine

the charge on the electron, receiving

the Nobel Prize in 1923,4 and

many others have been charging liquids

for numerous purposes, including

printing, since 1951.5

In IBF, liquids are charged also, and

that action allows the performance of

many simple, useful tasks including

flying nanoliter and microliter quantities

of liquids nontouch to targets

of all types, such as humans, plants,

and animals; microscope slides; multiple-well plates; and scientific instruments.6–12 Through the presentation of

the physics of IBF, it has been shown

that unlike piezoelectric, sound, or any

other technologies that are applied

to transport liquids, IBF technology

employs an electric field that can 1)

kinetically launch drops to targets of all

types, 2) dynamically direct the liquids

in flight (a very desirable, i.e., required,

trait for small volumes of liquids), and

3) count them on arrival. This simple

technology has been called “elegant”

by the director of R&D of a major mass

spectrometry firm,13 and is revisited

here along with new devices and applications

(see Figure 1).

Figure 1 - Nanoliter liquid handling, including 22 nL, 3×, at 60× magnification to a matrix-assisted laser desorption ionization (MALDI) target; 40 nL flown to thumb; nL (varied) flown from a Gilson pipet (Middleton, WI); nL from syringe flown into a multiple-well plate; writing picoliter with pL; ca. 35 nL on dime; 8 channels, 50-nL dispensings; and the parallel LC/MALDI (Nanoliter, LLC), μm-sized droplets directly from LC columns.

Why nanoliters, again?

The nanoliter regime offers a number

of obvious benefits over microliters and milliliters. These include

1) significant savings in expensive

reagents; 2) major reduction in

human exposure to toxic chemicals,

allergens, agents, viruses,

etc.; and 3) greatly reduced waste

disposal costs. Because IBF has a

massive dynamic range (μL to

fL), it has a substantial application

space. It is a useful laboratory

tool that has wide application in,

for example, simple sample dilution;

MALDI biomarkers sample

preparation; drug delivery; drug

discovery; radiochemistry; homeland

security and defense applications;

forensics; the sampling of

human beings; medical diagnostics

sample preparation; and in the

manufacture of unique chemical

and other entities, i.e., electrets.

These charged spheres of reagents

can be manipulated with fields to

effect unique liquid/solid handling

tasks. (These were originally called

nanoliter-sicles.) Finally, IBF

allows nontouch dispensing in the

microliter regime as well, for more

classical assays, and also has interesting

consumer applications.

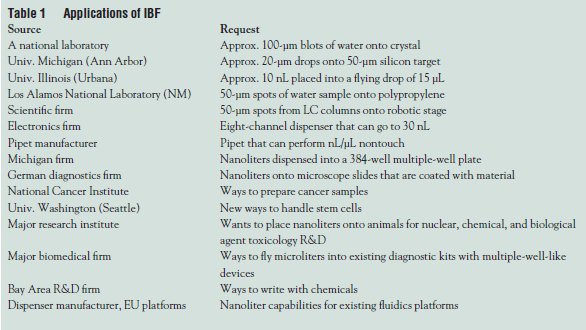

Applications

Of course there are countless routine

applications of the low-volume

dispensing and aspirating technology,

as given below. Applications

include sample preparation for

thin-layer chromatography (TLC),

or even simple sample dilution or

other sample handling tasks, which

can in fact be highly parallel. This includes the recently patented ability

to morph syringe, peristaltic, and

other pumps into nanoliter dispensers.

Moreover, IBF-based sample

preparation provides the ability to

save precious samples such as expensive

enzymes or evidence in forensic

settings, where disposable containers

can be the dispenser, minimizing

sample transfers and various loss

mechanisms. IBF can dispense, i.e.,

literally fly, nanoliter quantities of

highly viscous, complex liquids such

as glycerin, some glues and slurries,

and even heparinized whole human

blood to targets like microscope

slides, blotting media, and other

targets over short distances (μm)

to longer distances on the order of

meters using simple devices. In certain

settings, IBF can perform nanoliter

or other dispensings from inexpensive,

disposable patent-pending

pipet tips (www. nanoliter.com). IBF

applications demonstrating the wide

and varied interest in low-volume

dispensing are presented in Table 1.

With IBF, one can apply electric

fields of different shape, energy,

polarity, and intensity, and vary

them in countless other ways. Because of this, one can morph

existing traditional devices such

as syringes, pipets, pumps of all

types, LCs, solid-phase extraction (SPE) devices, and other instrument

introduction tools into

new, nontouch dispensing/sample

preparation devices simply by

appending IBF technology to existing

devices. Thus, common tools that are deployed in laboratories

and factories worldwide can take

on useful new attributes that can

facilitate the transport and treatment

of liquids from the macro

to micro to nano world and back,

often extending the dynamic range

of devices by 1, 2, or 3 orders of

magnitude. This property, the ability

to establish “world to nano”

connectivity or to provide a path

from the macro, micro, and nano

world, may prove to be one of the

most useful aspects of IBF. In fact,

one can place liquids onto humans

for drug delivery or sample them using a patent-pending

process

that is nondispersive (see

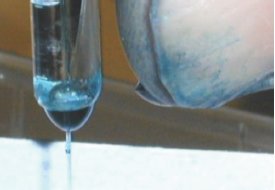

Figure 2).

Figure 2 - Liquid being pulled into a cone jet to the target from a human in a nondispersive manner.

Implementation

Recognizing that the technology

was originally introduced

at a very bad time historically,

i.e., September 2001,

one must wonder why the

nanoliter regime has not been

widely adopted given all of its

potential. One possible reason

was the lack of inexpensive,

commercially available tools. To,

in part, remedy this, the nanoliter,

microliter syringe was invented.

This simple device can morph any

common microliter syringe into a

nontouch nanoliter or microliter

dispenser (Nanoliter, LLC). In the

simplest applications, IBF technology

can now deliver cost-effective,

highly accurate, precise, routine,

economical nanoliter liquid handling

to laboratories worldwide.

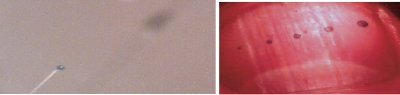

Figure 3 - The nanoliter, microliter syringe with ca. 40-nL dispensings of MALDI (α-cyano-4-hydroxycinnamic acid, CHCA) matrix on a MALDI Applied Biosystems (Foster City, CA) target. Circles are ca. 1 mm. Accurate volumetric and spatial sample placement can improve MALDI results by increasing sample homogeneity and by spatially concentrating analyte in spots the size of the laser beam, as compared to larger volumes of the dried droplet method that results in shooting target locales with no sample, generating prima facie-only noise.

The nanoliter, microliter syringe

(Figure 3) can morph standard microliter

syringes into a nontouch nanoliter

or microliter dispenser once

placed in the chamber. The same

device in 8- or N-channel mode

can place liquids into multiple-well

plates or on surfaces with the volumetric

and spatial accuracy needed

to improve MALDI quantitative and

qualitative analysis when coupled

with the programmable controller

(Nanoliter, LLC). This control can

be seen in a video at www.nanoliter.com

and in Figure 4, which shows the liquids

at the bottom of the multiplewell

plate instead of outside, or on

the sides of the wells, unlike other

technologies that do not dynamically

direct the liquid.

Figure 4 - Nanoliters flown into a multiple-well plate, the patented energy controller, and an IBF spray-based deposition tool based purely on induction.

It is important to realize that IBF

can be used to place samples anywhere,

flying them in simple or

complex trajectories from humans

(not just to them), to instruments,

up to targets (i.e., aspirating

them), down, left, or right, in

a manner completely analogous to

how gas phase ions are flown in

a mass spectrometer as given by

SIMION™ (the software developed

by David Dahl for ion and

electron optics simulation, see www.simion.com). Unlike gas

phase ions in mass spectrometers,

however, IBF-based liquid trajectories

must include other forces.

To understand IBF,5 consider the

physics of a flowing laminar system.

The liquid volume passing through

a tube is given by the Hagen Poiseuille

equation. (IBF does not need

hybrid systems, and the flow can

be purely electrokinetic, but that

is beyond the scope of this paper.)

The volume of fluid (V) that flows

down a small-diameter capillary

tube per unit of time (t) is proportional

to the radius of the tube (r),

the pressure pushing the fluid down

the tube (P), the length of the tube

(l), and the viscosity of the fluid

(η). Note, V is linear in t.

Now, if we grow a drop on a capillary

under these conditions, we can

then charge (q) the drop using an

electric field E to energize it. Upon

charging, the ions rapidly migrate

to the surface of the drop. Now that

the liquid is charged, it can experience

the electrical force (qE)

imparted by induction, similar to

the manner in which gas phase ions

experience the qE force in mass

spectrometers. Since electric fields

can be rapidly toggled on and off

with high accuracy and precision,

the forces on the liquid drops can be changed rapidly and accurately

as well.

Because F is a vector, we can direct

the drop if we shape the field. Thus,

for a charged drop with initial value,

q0, which depends on well-known

solution specifics,

we have a relaxation time, λ,

where λ= (ε0εr/κ), ε0 is the dielectric

constant of free space, εr is the

relative permittivity, κ is the solution

conductivity, t is time, and q

is defined.

Now, a charged liquid drop in an

electric field not only can experience

the qE force, but experiences

different forces as well in the atmosphere

in x, y, and z space, depending

on the specifics of the system, as

stated previously. Using standard,

well-known physics, Newton’s Second

law, we can equate the forces (electric, drag, buoyancy, gravity,

and coulombic) acting on a drop to

those acting in the direction, x, as:

Fx = m (ax) = m (dvx/dt) = Felec + Fdrag + Fbuoy + Fgrav + Fcoul

Force equations can also be written

for the y and z coordinates; therefore,

with accurate model equations

for Fy and Fz, we can actually calculate

the trajectories of the drops

(distances of travel, d) at any time,

t, knowing that Vx = dx/t, Vy = dy/t,

Vz = dx/t, and the initial position of

the drop, and that V2 = Vx2 + Vy2 +

Vz2, but that discussion is beyond the

scope of this paper.

Simple observations of charged liquids

Figure 5 - Visit www.nanoliter.com to see this drop fly up, i.e., aspirate to a thumb; ca. 7.5, 15, 22.5, 45, and 90 nL, estimated using stepper-motor digital readout in this case.

One aspect of IBF is the sometimes

counterintuitive ways that charged

matter behaves. For example, when

a liquid is charged to some value, q,

in a field of strength, E, with gravity

acting in the opposite direction,

the drop can be aspirated, i.e.,

it flies up (www.nanoliter.com). In

fact, it has been known for many

years that one can literally levitate

drops in laboratories. However, with

IBF and this new tool, the technology

can be applied to such activities

as depositing the liquids onto

targets for proteomics biomarkers/cancer disease diagnostics, drug delivery,

placing samples into scientific

instruments, simple dilution, conserving

precious reagents, and countless

other purposes (see Figure 5).