Food safety practices are a major public concern because about one in six Americans endured a food-related illness in 2010. In response to this disturbing statistic, President Obama signed the FDA Food Safety Modernization Act (FSMA) in January 2011, which directed the FDA to focus more on preventing food safety problems than reacting to problems after they occur. With increased enforcement authority, the FDA is now able to require demonstration of safe practices in the production, transport, and processing of both domestic and imported foods. “Authority” translates into “responsibility.” So let’s change the wording:

With increased enforcement responsibility, the FDA is now able to require a demonstration of safe practices in the production, transport, and processing of both domestic and imported foods. This responsibility is a huge mandate, especially when food and drugs account for just over one trillion dollars of an economy with a GDP of $14.5 trillion in 2010. However, the preamble to the act specifically encouraged cooperation between academia, regulators, and industry.

With this as an introduction, I interviewed Dr. Janie Dubois, Manager of the IFSTL (International Food Safety Training Laboratory) at JIFSAN (Joint Institute for Food Safety and Applied Nutrition) of the University of MD (College Park) campus.

Risk analysis in the food sector

RS: FDA is an acknowledged global leader in science-based regulation. Recently, this has included risk-based sorting to focus resources on items of highest risk. What risks are on today’s radar screen?

JD: Indeed, risk analysis plays a vital role in the regulation, and in the allocation of resources, for testing. In the food sector, we worry about the risk of a product causing disease, especially in the weakest segments of the population such as infants, children, the elderly, and persons with weakened immune systems. There are foods that are intrinsically at higher risk for chemical or microbial contamination, and they receive more attention. The risk evolves as society changes; for example, industrialization and urbanization increased the risk associated with food due to the increased distance from production leading to longer transportation and storage. One thing that is new on today’s radar screen is the prevalence of imported foods in today’s diet. For example, it has become normal to eat fruits and vegetables all year round, regardless of whether it is the right season in our region.

RS: Is appropriate technology available for protecting us from the present and future risks?

JD: Food safety monitoring today uses a variety of techniques taken from many disciplines. These are selected to fit the purpose. Agar works well for quick and inexpensive screening for presence of bacteria. However, if one needs to know if a new event involves a new or old pathogen, this requires much more sophisticated instrumentation and techniques. Fortunately, new analytical techniques are evolving rapidly. Also, we must consider the entire work flow, including the capability of the analyst. Training is the key here. Training is not sufficient in itself, but lack of training will compound the problem.

RS: How are methods and results evaluated?

JD: The methods themselves are selected based on the fitness for purpose, i.e., how they are able to measure a component or multiple components found within food matrices. They include steps of sample preparation and extraction that are often specific for groups of food commodities. Recognized organizations, such as AOAC (Association of Official Analytical Chemists), publish these methods, and the FDA and other agencies in the U.S. and around the world evaluate the fit-for-purpose and recommend how the food shall be tested in their laboratories. Results are evaluated in a similar manner where the method used must fit the problem and be at least equivalent to the recommendation, the personnel involved must be qualified, and the results must be validated.

Preventing food-related illnesses

RS: The FSMA has a long-term goal of reducing problems caused by food. How do you see this happening?

JD: One of the difficulties in food testing is that we are looking for rare events in commodities that must reach consumers quickly. For example, fresh fish or fruits may spoil in a matter of days, even when kept in the best possible storage conditions. We must have methods that rapidly and unambiguously differentiate between good and bad.

The food supply in the United States is surprisingly safe considering the volume and diversity of the distribution. Still, we lose 3000 lives per year to food diseases. Think about it—food is an unparalleled commodity: Every person on the planet needs to eat food; consumption happens 24 hours a day and in a variety of settings. Food is stored and transported to both the most remote and most densely populated areas of the world, etc. When a food is found unsafe in any of these environments, the world press jumps on the entire industry; investigations later determine which part of the supply chain, all the way to the home consumption of the food, led to the problem. Corrective measures may then be put in place to avoid a similar occurrence in the future.

What the new law says is that we need to take a preventative approach to minimize the risk of adverse events. Beyond implementing sound agricultural and manufacturing practices, we must also monitor some foods. As we study events associated with unsafe food, we see patterns and can understand where interventions are needed. With good testing, we will have the data to identify and propose solutions to deficiencies in the food supply.

Sample collection and risk assessment

Figure 1 – Student preparing various food samples for assay.

RS: Can we rely on testing to ensure that our food is safe? Is infallibility really a practical goal? Sampling seems to be a potential weak point. Who collects the samples and how? How representative are these? How vulnerable is the process to adulteration or selective sampling?

JD: We cannot rely on food testing alone, and that is one of the reasons there is a strong focus on prevention and putting safeguards along the chain from farm to our tables, no matter where the food is from.

Sampling and sample processing is indeed a key concern (see Figure 1). Which shipments, lots, or even crates get sampled and how sampling is done are determined through risk analysis and statistical techniques. It is usually the greatest potential source of error for our analytical results, but again, a good understanding of the problem and proper training can help ensure appropriate sampling. In addition, there has been a growth in recent years of requirements for certification in a number of points in the path from farm to fork, which will help increase compliance to accepted sampling procedures through education.

The sample load for a laboratory needs to be evaluated and planned in a realistic manner. There is no magic bullet, but there are many tools to increase the analytical capacity of a laboratory. And, of course, proper risk assessment enables the selection of higher-risk products to jump the queue.

Training in food safety/conclusion

Figure 2 – The laboratory is purpose-built for training, as shown for the workstations for sample prep.

RS: During the last year, some of the food problems—cucumbers and cantaloupes, in particular—were traced to domestic sources. How should domestic food providers, including labs, take advantage of the IFSTL?

JD: The IFSTL is a training facility for fit-for-purpose laboratory methods in food safety (see Figure 2). We are one of many programs in the Joint Institute for Food Safety and Applied Nutrition, a partnership between the University of Maryland and the U.S. FDA, with a 15-year history of education, outreach, and research in Good Agriculture, Good Aquaculture Practices (GAP and GAqP), commercially sterilized packaged foods, risk analysis, and risk assessment. Our liaisons and numerous collaborators at FDA, but also at USDA, help us define priorities for training, and we respond by planning specific courses. In some cases, a course may be designed to answer a need for training in a region where it is hard to obtain and we may consequently invite only participants from that region. Regionally focused groups also enable us to offer language support for participants who have difficulty following in English. In other cases, there may be a broad need for training, and we will not specify a region. Finally, and to the point of your question, sometimes there is a need in the United States and we tailor the course for a U.S. audience. One such example is a course we delivered in the fall of 2011 on the microscopic identification of botanicals used in dietary supplements; there are few experts in this field and it is difficult to obtain training, so we gathered three experts from FDA and trained a group of Americans working in the dietary supplements industry.

RS: The IFSTL program decided to focus on training. Why? How are training courses selected?

JD: Training is key to risk mitigation. We simply must deliver results that are reliable. We may be able to test only a small fraction of potential samples, but what we test, we must correctly classify. An important difference in the training offered at IFSTL is that we design the schedule to include presentations from a group of government experts to review the regulation, explain the state of situation (like the rate of noncompliance and reasons if they are known), what it means for producers, importers, or even countrywide groups of producers and importers when one falls in noncompliance. These are topics that many laboratory workers are less familiar with, but understanding them emphasizes the importance of the laboratory results that they will be producing with the methods that they will learn and practice in our course. We then bring in a different group of government and academic experts to explain and help the students practice the necessary laboratory methods.

RS: What about training in basic laboratory technology such as pipets? These are ubiquitous, but the proficiency of many users is poor.

JD: We include some aspects of basic laboratory skills as we see fit based on the skills of the participants, but we typically do not assign time per se for these skills. There are training programs that are available for a variety of topics and we need to keep our focus on food safety methods. What is different about the IFSTL is the training from expert scientists used to define or enforce regulations, so we want to focus on that.

RS: Is training enough? Do we need standard methods or protocols?

JD: We are training on methods that are published, some with more detailed protocols than others. There is no book available that covers all methods. Methods are recommended based on how well they fit the purpose and there are often multiple methods that work well enough to be recommended. The regulatory framework will be different than drugs or environmental. No USP analog is expected. Standards are required for some methods, and laboratory accreditation is already fairly widespread in developed countries, but it is expected to play an increasingly important role when evaluating the safety of foods. The FSMA will define new requirements in this field that will benefit public health.

RS: Who is responsible for the costs of testing? The grower? Packing operator? Shipper? Receiver? Retailer? Consumer?

JD: The testing is done by different organizations, depending on the country and the structure of the trade system; some private companies do their own testing and some send it out to contract laboratories. For imported products, the FSMA is placing the burden of assuring quality and safety on the importer, which is really the only stakeholder that has any filings with the U.S. government for any given shipment. The cost of testing is part of the cost of a commodity, and in the end, products must be produced, transported, transformed, and tested, for a total cost that the consumer is willing to bear.

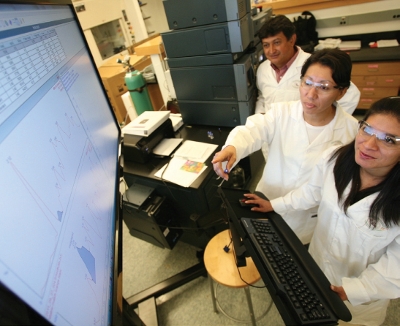

Figure 3 – Students using state-of-the-art UPLC®-MS (Waters Corp., Milford, MA) for assay of food samples they have prepared.

RS: What is the career path for your graduates?

JD: Our participants are professionals in the field of laboratory analysis and even more specifically in the analysis of food. The knowledge and skills they gain in our training course can have a significant impact on their career because they gain an insight into regulations and the rationale behind testing, tolerances, compliance levels, and a number of other sectors that are rarely taught to laboratory workers (see Figure 3). In addition, we try to promote a spirit of partnership and sharing between participants to help workers from less developed laboratories learn how more advanced laboratories in their region took steps to modernize and grow. By understanding why compliance levels are set and the methods that can be used to test food, we envision a move to harmonize the methods that get used worldwide through exchange and validation.

We hope to see some of our participants move into the regulatory sciences, and that the connections established between participants and with the trainers will help promote a better understanding of the food safety situation globally, and ultimately improve public health

Robert L. Stevenson, Ph.D., is a Consultant and Editor of Separation Science for American Laboratory/Labcompare; e-mail: [email protected].